Product Description

Starshine Drive Cycloid Geared Motor Characteristics

1. Features:

1. Smooth running,low noise gear tooth needle more engagement.

2. Cycloidal tooth profile provides a high contact ratio to withstand overload shocks

3. Compact size: single ratio available from 1/9 to 1/87, double stage up from 1/99 to 1/7569

4. Ideal for dynamic applications: frequent start-stop-reversing duties suits for cyclo speed reducer since inertia is low

5. Reduce maintenance costs: high reliability, long life, minimal maintenance compared to conventional gearboxes

6. Internal parts replaceable with other brands to ensure running.

7. Grease Lubricated & Oil Lubricated Models Available

8. Output Shaft Rotation Direction: Single Reduction: Clockwise Rotation; Double Reduction→ Counter Clockwise Rotation

9. Ambient Conditions: Indoor Installation:10-40 Celsius, Max 85% Humidity, Under 1000m Altitude, Well Ventilated Environment, Free of corrosive, explosive gases, vapors and dust

10.Slow Speed Shaft Direction: Horizontal, Vertical Up & Down, Universal Direction

11.Mounting Style: Foot Mount, Flange Mount & Vertical F-flange Mount,

12. Input Connection: Cyclo Integral Motor, Hollow Input Shaft Adapter

13. Coupling Method With Driven Machine: Coupling, Gears, Chain Sprocket Or Belt

14. Cycloid reducer Capacity Range: 0.37kW ~ 11kW;

2. Technical parameters

| Type | Old Type | Output Torque | Output Shaft Dia. |

| SXJ00 | JXJ00 | 98N.m | φ30 |

| SXJ01 | JXJ01 | 221N.m | φ35 |

| SXJ02 | JXJ02 | 448N.m | φ45 |

| SXJ03 | JXJ03 | 986N.m | φ55 |

| SXJ04 | JXJ04 | 1504N.m | φ70 |

| SXJ05 | JXJ05 | 3051N.m | φ90 |

| SXJ06 | JXJ06 | 5608N.m | φ100 |

About Us

ZheJiang CHINAMFG Drive Co.,Ltd,the predecessor was a state-owned military mould enterprise, was established in 1965. CHINAMFG specializes in the complete power transmission solution for high-end equipment manufacturing industries based on the aim of “Platform Product, Application Design and Professional Service”.

CHINAMFG have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CHINAMFG and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our Team

Quality Control

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend;

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

product is a product inspection to determine the qualified products.

7. Certification.

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Agricultural Machinery, Ceramic |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical or Horizotal Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary Conedisk Friction Type |

| Step: | Stepless |

| Customization: |

Available

|

|

|---|

What are the maintenance requirements for gear motors, and how can longevity be maximized?

Gear motors, like any mechanical system, require regular maintenance to ensure optimal performance and longevity. Proper maintenance practices help prevent failures, minimize downtime, and extend the lifespan of gear motors. Here are some maintenance requirements for gear motors and ways to maximize their longevity:

1. Lubrication:

Regular lubrication is essential for gear motors to reduce friction, wear, and heat generation. The gears, bearings, and other moving parts should be properly lubricated according to the manufacturer’s recommendations. Lubricants should be selected based on the motor’s specifications and operating conditions. Regular inspection and replenishment of lubricants, as well as periodic oil or grease changes, should be performed to maintain optimal lubrication levels and ensure long-lasting performance.

2. Inspection and Cleaning:

Regular inspection and cleaning of gear motors are crucial for identifying any signs of wear, damage, or contamination. Inspecting the gears, bearings, shafts, and connections can help detect any abnormalities or misalignments. Cleaning the motor’s exterior and ventilation channels to remove dust, debris, or moisture buildup is also important in preventing malfunctions and maintaining proper cooling. Any loose or damaged components should be repaired or replaced promptly.

3. Temperature and Environmental Considerations:

Monitoring and controlling the temperature and environmental conditions surrounding gear motors can significantly impact their longevity. Excessive heat can degrade lubricants, damage insulation, and lead to premature component failure. Ensuring proper ventilation, heat dissipation, and avoiding overloading the motor can help manage temperature effectively. Similarly, protecting gear motors from moisture, dust, chemicals, and other environmental contaminants is vital to prevent corrosion and damage.

4. Load Monitoring and Optimization:

Monitoring and optimizing the load placed on gear motors can contribute to their longevity. Operating gear motors within their specified load and speed ranges helps prevent excessive stress, overheating, and premature wear. Avoiding sudden and frequent acceleration or deceleration, as well as preventing overloading or continuous operation near the motor’s maximum capacity, can extend its lifespan.

5. Alignment and Vibration Analysis:

Proper alignment of gear motor components, such as gears, couplings, and shafts, is crucial for smooth and efficient operation. Misalignment can lead to increased friction, noise, and premature wear. Regularly checking and adjusting alignment, as well as performing vibration analysis, can help identify any misalignment or excessive vibration that may indicate underlying issues. Addressing alignment and vibration problems promptly can prevent further damage and maximize the motor’s longevity.

6. Preventive Maintenance and Regular Inspections:

Implementing a preventive maintenance program is essential for gear motors. This includes establishing a schedule for routine inspections, lubrication, and cleaning, as well as conducting periodic performance tests and measurements. Following the manufacturer’s guidelines and recommendations for maintenance tasks, such as belt tension checks, bearing replacements, or gear inspections, can help identify and address potential issues before they escalate into major failures.

By adhering to these maintenance requirements and best practices, the longevity of gear motors can be maximized. Regular maintenance, proper lubrication, load optimization, temperature control, and timely repairs or replacements of worn components contribute to the reliable operation and extended lifespan of gear motors.

Can you explain the role of backlash in gear motors and how it’s managed in design?

Backlash plays a significant role in gear motors and is an important consideration in their design and operation. Backlash refers to the slight clearance or play between the teeth of gears in a gear system. It affects the precision, accuracy, and responsiveness of the gear motor. Here’s an explanation of the role of backlash in gear motors and how it is managed in design:

1. Role of Backlash:

Backlash in gear motors can have both positive and negative effects:

- Compensation for Misalignment: Backlash can help compensate for minor misalignments between gears, shafts, or the load. It allows a small amount of movement before engaging the next set of teeth, reducing the risk of damage due to misalignment. This can be particularly beneficial in applications where precise alignment is challenging or subject to variations.

- Negative Impact on Accuracy and Responsiveness: Backlash can introduce a delay or “dead zone” in the motion transmission. When changing the direction of rotation or reversing the load, the gear teeth must first overcome the clearance or play before engaging in the opposite direction. This delay can reduce the overall accuracy, responsiveness, and repeatability of the gear motor, especially in applications that require precise positioning or rapid changes in direction or speed.

2. Managing Backlash in Design:

Designers employ various techniques to manage and minimize backlash in gear motors:

- Tight Manufacturing Tolerances: Proper manufacturing techniques and tight tolerances can help minimize backlash. Precision machining and quality control during the production of gears and gear components ensure closer tolerances, reducing the amount of play between gear teeth.

- Preload or Pre-tensioning: Applying a preload or pre-tensioning force to the gear system can help reduce backlash. This technique involves introducing an initial force or tension that eliminates the clearance between gear teeth. It ensures immediate contact and engagement of the gear teeth, minimizing the dead zone and improving the overall responsiveness and accuracy of the gear motor.

- Anti-Backlash Gears: Anti-backlash gears are designed specifically to minimize or eliminate backlash. They typically feature modifications to the gear tooth profile, such as modified tooth shapes or special tooth arrangements, to reduce clearance. Anti-backlash gears can be used in gear motor designs to improve precision and minimize the effects of backlash.

- Backlash Compensation: In some cases, backlash compensation techniques can be employed. These techniques involve monitoring the position or movement of the load and applying control algorithms to compensate for the backlash. By accounting for the clearance and adjusting the control signals accordingly, the effects of backlash can be mitigated, improving accuracy and responsiveness.

3. Application-Specific Considerations:

The management of backlash in gear motors should be tailored to the specific application requirements:

- Positioning Accuracy: Applications that require precise positioning, such as robotics or CNC machines, may require tighter backlash control to ensure accurate and repeatable movements.

- Dynamic Response: Applications that involve rapid changes in direction or speed, such as high-speed automation or servo control systems, may require reduced backlash to maintain responsiveness and minimize overshoot or lag.

- Load Characteristics: The nature of the load and its impact on the gear system should be considered. Heavy loads or applications with significant inertial forces may require additional backlash management techniques to maintain stability and accuracy.

In summary, backlash in gear motors can affect precision, accuracy, and responsiveness. While it can compensate for misalignments, backlash may introduce delays and reduce the overall performance of the gear motor. Designers manage backlash through tight manufacturing tolerances, preload techniques, anti-backlash gears, and backlash compensation methods. The management of backlash depends on the specific application requirements, considering factors such as positioning accuracy, dynamic response, and load characteristics.

How does the gearing mechanism in a gear motor contribute to torque and speed control?

The gearing mechanism in a gear motor plays a crucial role in controlling torque and speed. By utilizing different gear ratios and configurations, the gearing mechanism allows for precise manipulation of these parameters. Here’s a detailed explanation of how the gearing mechanism contributes to torque and speed control in a gear motor:

The gearing mechanism consists of multiple gears with varying sizes, tooth configurations, and arrangements. Each gear in the system engages with another gear, creating a mechanical connection. When the motor rotates, it drives the rotation of the first gear, which then transfers the motion to subsequent gears, ultimately resulting in the output shaft’s rotation.

Torque Control:

The gearing mechanism in a gear motor enables torque control through the principle of mechanical advantage. The gear system utilizes gears with different numbers of teeth, known as gear ratio, to adjust the torque output. When a smaller gear (pinion) engages with a larger gear (gear), the pinion rotates faster than the gear but exerts more force or torque. This results in torque amplification, allowing the gear motor to deliver higher torque at the output shaft while reducing the rotational speed. Conversely, if a larger gear engages with a smaller gear, torque reduction occurs, resulting in higher rotational speed at the output shaft.

By selecting the appropriate gear ratio, the gearing mechanism effectively adjusts the torque output of the gear motor to match the requirements of the application. This torque control capability is essential in applications that demand high torque for heavy lifting or overcoming resistance, as well as applications that require lower torque but higher rotational speed.

Speed Control:

The gearing mechanism also contributes to speed control in a gear motor. The gear ratio determines the relationship between the rotational speed of the input shaft (driven by the motor) and the output shaft. When a gear motor has a higher gear ratio (more teeth on the driven gear compared to the driving gear), it reduces the output speed while increasing the torque. Conversely, a lower gear ratio increases the output speed while reducing the torque.

By choosing the appropriate gear ratio, the gearing mechanism allows for precise speed control in a gear motor. This is particularly useful in applications that require specific speed ranges or variations, such as conveyor systems, robotic movements, or machinery that needs to operate at different speeds for different tasks. The speed control capability of the gearing mechanism enables the gear motor to match the desired speed requirements of the application accurately.

In summary, the gearing mechanism in a gear motor contributes to torque and speed control by utilizing different gear ratios and configurations. It enables torque amplification or reduction, depending on the gear arrangement, allowing the gear motor to deliver the required torque output. Additionally, the gear ratio also determines the relationship between the rotational speed of the input and output shafts, providing precise speed control. These torque and speed control capabilities make gear motors versatile and suitable for a wide range of applications in various industries.

editor by CX 2024-04-25

in Concepcion Chile sales price shop near me near me shop factory supplier Bw Single-Step Cycloidal Stainless Steel Horizontal Pinwheel Motor Reducer manufacturer best Cost Custom Cheap wholesaler

Our AdvantagesProducts Massive volume in Stock, No MOQ essential We comply with all the international requirements, this kind of as ISO9001 and TS16949 specifications. Our major products are Needle Roller bearings, Cylindrical Roller Bearings, Rod conclude Bearings, Spherical simple bearings, Observe roller Bearings for Guideway, Roller Bearings, Blend Bearings for forklifts, H2o Pump Bearings, SNR Vehicle Bearings and all kinds of Spherical Bearings. In this way, our products have ongoing to obtain industry acceptance and clients pleasure more than the earlier few years.

XWD2/ XWD3/XWD4/XWD5/XWD6/XWD7 /XWD8 EPTT with ac motor

Cycloidal EPTT adopts meshing cycloid pin EPT, planetary EPTT basic principle, so generally also named planetary cycloid EPTT. Planetary cycloidal EPTT can be extensively employed in petroleum, environmental security, chemical, cement, transport, textile, pharmaceutical, food, printing, lifting, mining, metallurgy, development, EPTT era and other EPTT.

As a EPT or reduction EPT, the EPTT is divided into horizontal, vertical, biaXiHu (West EPT) Dis.al and straigEPTT league assembly way,and so forth. Its EPT steady structure can exchange ordinary cylindrical EPT EPTT and worm EPT EPTT in a lot of situations. As a result, planetary cycloid EPT EPTT is commonly used in various EPTT and fields, and is EPTTly welcomed by the vast majority of end users.

XWD/BWY cycloid EPTT motor particulars:

B collection:

BW basedoard horizontal set up double axes sort

BL flange vertical installed double axes sort

BWY basedoard horizontal put in motor immediate-connection sort

BLY flange vertical mounted motor direct-relationship type

X collection:

XW basedoard horizontal put in double axes kind

XL flange vertical put in double axes type

XWD basedoard horizontal put in motor immediate-link sort

XLD flange vertical put in motor immediate-relationship type

FAQ

one, Q:what’s your MOQ for ac EPEPT ?

A: 1pc is alright for each kind electric powered EPT box motor

2, Q: What about your warranty for your induction speed EPEPT ?

A: 1 12 months ,but apart from gentleman-created ruined

three, Q: which payment way you can settle for ?

A: TT, western union .

4, Q: how about your payment way ?

A: a hundred%payment in EPTd less $5000 ,thirty% payment in EPTd payment , 70% payment prior to sending in excess of $5000.

five, Q: how about your EPTT of speed reduction motor ?

A: plywood scenario ,if measurement is modest ,we will pack with pallet for significantly less one container

6, Q: What information need to be presented, if I acquire electric helical EPTed motor from you ?

A: rated EPTT, ratio or output speed,kind ,voltage , mounting way , quantity , if more is EPT ,

in Konya Turkey sales price shop near me near me shop factory supplier Cycloidal Gearbox Cyclo Speed Drive Planetary Gear Motor Sumitomo Pins Planetary Bwd Xwed Cycloid Gearbox Robot Reducer Stainless Steel manufacturer best Cost Custom Cheap wholesaler

Having accumulated treasured knowledge in cooperating with international buyers, EPG is a expert manufacturer and exporter that is involved with the design and style, improvement and creation. The new products incorporate a series of higher-tech and high high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, large-pace tooth chains, timing chains, self-lubrication chains, amongst which have variety large speed tooth chain for vehicle branch dynamic box and aerial chains fill in the blanks of chain in China.

Cycloidal EPT cyclo velocity generate planetary equipment motor sumitomo pins planetary bwd xwed cycloid EPT robot EPT stainless steel

in Hufuf-Mubarraz Saudi Arabia sales price shop near me near me shop factory supplier Low Price B09 Cycloidal Pin Gear Reducer Horizontal Gearbox Bwd Bld Cycloid Reducer Gearbox manufacturer best Cost Custom Cheap wholesaler

The team has taken part in the generating and revising of ISO/TC100 worldwide chain regular numerous several years in achievement and hosted the 16th ISO/TC100 Worldwide annual meeting in 2004. Retaining in head that excellent support is the key to cooperating with clientele, we try to meet substantial quality expectations, supply competitive charges and make sure prompt shipping. Great interest has been paid on environmental security and power saving.

XWD2/ XWD3/XWD4/XWD5/XWD6/XWD7 /XWD8 EPT with ac motor

Cycloidal EPT adopts meshing cycloid pin gear, planetary EPT principle, so generally also called planetary cycloid EPT. Planetary cycloidal EPT can be extensively used in petroleum, environmental defense, chemical, cement, transportation, textile, pharmaceutical, meals, printing, lifting, mining, metallurgy, development, EPT technology and other EPT.

As a travel or reduction equipment, the EPT is divided into horizontal, vertical, biaXiHu (West Lake) Dis.al and straigEPT league assembly way,etc. Its EPT secure framework can change normal cylindrical gear EPT and worm gear EPT in numerous situations. EPTrefore, planetary cycloid equipment EPT is broadly utilized in various EPT and fields, and is EPTly welcomed by the bulk of customers.

XWD/EPTWY cycloid EPT motor information:

EPT sequence:

EPTW basedoard horizontal mounted double axes sort

EPTL flange vertical put in double axes type

EPTWY basedoard horizontal set up motor direct-link sort

EPTLY flange vertical set up motor direct-relationship type

X sequence:

XW basedoard horizontal installed double axes variety

XL flange vertical installed double axes type

XWD basedoard horizontal put in motor direct-link variety

XLD flange vertical installed motor direct-connection kind

FAQ

one, Q:what is actually your MOQ for ac EPT motor ?

A: 1pc is ok for every type electric gear box motor

2, Q: What about your warranty for your induction speed EPT motor ?

A: a single yr ,but apart from male-created wrecked

three, Q: which payment way you can settle for ?

A: TT, western union .

four, Q: how about your payment way ?

A: 100%payment EPTd much less $5000 ,thirty% payment EPTd payment , 70% payment ahead of sending above $5000.

5, Q: how about your EPT of speed reduction motor ?

A: plywood case ,if dimensions is modest ,we will pack with pallet for much less one particular container

6, Q: What information ought to be presented, if I buy electrical helical geared motor from you ?

A: rated EPT, ratio or output velocity,type ,voltage , mounting way , quantity , if much more is greater ,

in Malegaon India sales price shop near me near me shop factory supplier The Welcomed Foot Mounted Xb Series Cycloidal Reducer manufacturer best Cost Custom Cheap wholesaler

Our organization pays particular interest to customers’ demands, listening to the particular requirements of each and every buyer and guaranteeing complete pleasure. With many years’ knowledge in these lines, we have been distinguished from other suppliers in China by our rewards in competitive pricing, on-time shipping, prompt responses, on-hand engineering help and excellent after-product sales companies. The group is focused on generating all variety of regular roller chains and sprockets, gears & gearboxes, these kinds of as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just offered its merchandise all above china, but also marketed much more than sixty five% products to oversees, including Europe, America, South-east Asia, and it also has established up storage logistics in places like Europe.

The Welcomed Foot Mounted Xb Series Cycloidal EPT

Components:

one. Housing: Cast Iron

two. Gearset: Cycloid Wheel amp Pin Wheel

3. Input Configurations:

Geared up with Electric Motors (AC Motor, EPTrake Motor, Explosion-proof Motor, Regulated Pace Motor, Hydraulic Motor)

IEC-normalized Motor Flange

Keyed Reliable Shaft Enter

four. Output Configurations:

Keyed Strong Shaft Output

Functions:

1. Large reduction ratio, 1-stage ratio 9~87, 2-phase ratio 121~1849, larger reduction ratio is accessible by 3-phase or multistage combinations

2. High effectiveness, the typical efficiency is more than ninety%

3. Compact construction, ligEPT fat

four. Stable and reputable operation, reduced noise5. EPT service lifestyle

Parameters:

| Versions | EPT | Ratio | Max. Torque | Output Shaft Dia. | Input Shaft Dia. |

| one Phase | |||||

| X2(EPT0/EPT12) | .37~1.5 | 9~87 | 150 | Phi25( Phi30) | Phi15 |

| X3(EPT1/EPT15) | .55~2.2 | nine~87 | 250 | Phi35 | Phi18 |

| X4(EPT2/EPT18) | .75~4. | nine~87 | 500 | Phi45 | Phi22 |

| X5(EPT3/EPT22) | 1.5~7.5 | nine~87 | 1,000 | Phi55 | Phi30 |

| X6(EPT4/EPT27) | 2.two~eleven | nine~87 | 2,000 | Phi65( Phi70) | Phi35 |

| X7 | 3.~eleven | 9~87 | two,seven-hundred | Phi80 | Phi40 |

| X8(EPT5/EPT33) | 5.five~eighteen.5 | 9~87 | four,five hundred | Phi90 | Phi45 |

| X9(EPT6/EPT39) | 7.5~thirty | nine~87 | seven,one hundred | Phi100 | Phi50 |

| X10(EPT7/EPT45) | 15~forty five | 9~87 | 12,000 | Phi110 | Phi55 |

| X11(EPT8/EPT55) | 18.5~55 | nine~87 | twenty,000 | Phi130 | Phi70 |

| two Phase | |||||

| X32(EPT10) | .twenty five~.55 | 121~1849 | – | Phi35 | Phi15 |

| X42(EPT20/EPT1812) | .37~.75 | 121~1849 | – | Phi45 | Phi15 |

| X53(EPT31/EPT2215) | .55~1.five | 121~1849 | – | Phi55 | Phi18 |

| X63(EPT41/EPT2715) | .seventy five~2.2 | 121~1849 | – | Phi65( Phi70) | Phi18 |

| X64(EPT42/EPT2718) | .seventy five~two.2 | 121~1849 | – | Phi65( Phi70) | Phi22 |

| X74 | 1.one~3. | 121~1849 | – | Phi80 | Phi22 |

| X84(EPT52/EPT3318) | 1.5~4. | 121~1849 | – | Phi90 | Phi22 |

| X85(EPT53/EPT3322) | two.two~5.5 | 121~1849 | – | Phi90 | Phi30 |

| X95(EPT63/EPT3922) | three.~7.5 | 121~1849 | – | Phi100 | Phi30 |

| X106(EPT74/EPT4527) | 4.~11 | 121~1849 | – | Phi110 | Phi35 |

| X117(EPT84/EPT5527) | 4.~fifteen | 121~1849 | – | Phi130 | Phi40( Phi35) |

one Stage Ratio: nine, 11, 17, 23, 29, 35, forty three, fifty nine, 71, 87

two Phase Ratio: 121, 187, 289, 385, 473, 595, 731, 989, 1225, 1849

Set up:

Foot Mounted

Flange Mounted

Lubrication:

| – | Foot-mounted | Flange-mounted | ||

| one Phase | X2~X4 | X5~X11 | X2~X4 | X5~X11 |

| Grease Lubrication | Oil-bathtub amp Splash Lubrication | Grease Lubrication | Oil Pump Circulation Lubrication | |

| two Phase | X32~X42 | X53~X117 | X32~X42 | X53~X117 |

| Grease Lubrication | Oil-bath amp Splash Lubrication | Grease Lubrication | Oil Pump Circulation Lubrication | |

Cooling:

Organic Cooling

product pictures:

Our business :

EPT reg was launched in 1982, which has a lot more than 36 years in R amp D and production of EPTes, gears, shaft, motor and spare elements.

We can provide the suitable solution for uncountable apps. Our merchandise are widely used in the ranges of metallurgical, steel, mining, pulp and paper, suXiHu (West Lake) Dis.Hu (West Lake) Dis. and alcoholic beverages industry and various other types of EPTs with a strong existence in the global industry.

EPT reg has turn into a trustworthy supplier, in a position to source higher high quality EPTes.With 36 years expertise, we assure you the utmost dependability and stability for both merchandise and services.

Buyer browsing:

FAQ:

one.Q:What varieties of EPT can you generate for us?

A:Principal products of our organization: UDL series pace variator,RV series worm gear EPT, ATA sequence shaft mounted EPT, X,EPT sequence equipment EPT,

P series planetary EPT and R, S, K, and F collection helical-tooth EPT, far more

than one particular hundred versions and countless numbers of specs

two.Q:Can you make as for every personalized drawing?

A: Indeed, we supply customized services for buyers.

3.Q:What is your conditions of payment ?

A: thirty% Advance payment by T/T soon after signing the contract.70% prior to delivery

4.Q:What is your MOQ?

A: one Established

Welcome to make contact with us for far more element data and inquiry.

If you have specific parameters and need for our EPT, customization is obtainable.

in Rasht Iran (Islamic Republic of) sales price shop near me near me shop factory supplier B Jxj Series Cycloidal Gear Reducer manufacturer best Cost Custom Cheap wholesaler

“We are usually serving our clients with our ideal merchandise.” We have exported our products to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states, Canada, etc. With EPG brand name registered in more than 70 international locations like America , Europe , Japan and so on, it has partners between globe best enterprises, this kind of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and many others. EPT solJXJ Series Cycloidal Gear EPT with EPTig Ratio

| Product | EPT solJXJ cycloid pin wheel EPT |

| EPTase No periodSingle Stage | num-6 num lparsingle phase rpar comma10 num-sixty three num lpardoubel phase rpar |

| Colours | EPTlue or OEM hues |

| Enter EPT | period37-30KW |

| Ratio | nine-87 lparsingle stage rpar comma81-7569 lpardouble phase rpar |

| Output Torque | 16 period96-7100Nm |

| Maint components | EPTase commaoutput shaft commacycloid equipment commagear pin commagear roller commaoutput shaft ring |

| Maint parts content | GCr15 |

| Lubrication | forty num EPT oil solCKC460 EPT oil |

| Performance | eighty percnt-85 percnt |

| Rotation | Obverse or reverse rotation |

in Kampala Uganda sales price shop near me near me shop factory supplier Cycloidal Pin-Wheel Gear Reducer Bld Xld Flange Mount Reducer manufacturer best Cost Custom Cheap wholesaler

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

Best China manufacturer & factory china in Lodz Poland supplier BWD BLD 2 Series 1:40 ratio cycloidal gearbox gear reducer for concrete transit mixer with TB support With high quality best price

we offer one-stop solution for the purchase of mechanical chain,power transmission parts and pto shaft, agricultural gearboxes products in China.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Pole:

-

one two three four six Stage

- Ratio:

-

11-87

- Housing Material:

-

Cast Iron

- Working temperature:

-

-40~45℃

- Application:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

- Type:

-

1:40 ratio cycloidal gearbox gear reducer for concrete transit mixer

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 1 >1 Est. Time(days) 8 To be negotiated

Online Customization

Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.

Product Description

XW(D) Series Cycloid Speed Reducer

EPG——industrial gearbox manufacturers

BWD BLD 2 Series 1:40 ratio cycloidal gearbox gear reducer for concrete transit mixer with TB support

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B serTECHNOLOGY LEADER IN THE DRIVES SECTOR Controlling movement with the highest precision – this challenge has been driving WITTENSTEIN for over 30 years now. This great determination has helped us become an undisputed global technology and quality leader.ies gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

Cycloidal Pinwheel Reducer is a speed reducing construction with advance design,novel structure adopting the principle of planet driving and the falling-in of cycloidal pin gear. It is widely applied to the speed reducing structure of various driving machineries ,such as lift ,transportation,mine,metallurgy,petrolchemical,texitile,prention,lightindustry,pharmacy,food,forage,food machinery,ect.

Feature:

- 1. Big Volecity- Reducing RatSFI M100 PTO AdapterAs a precautionary measure, it is a good idea to purchase a PTO adapter to ensure compatibility with your particular tractor model.io:Ratio of single-stage speed-reducing is 1/11-1/87; Ratio of double stage speed-reducing is 1/112-1/5133;Ratio of three-stage speed-reducing is 1/2057-1/446571;more-stages can be combined according to the requirement.

-

2. High driving efficiency:Due to adopting rolling engagement in falling-in part, the driving efficiency can reach above 90%.

-

3. Small in size, light weight: with compacted structure,small size and light weight. Due to adopting the principle of planet driving so that the input and output shaft in the same axis which will integrated with the motor.

-

4. Long service life: Has good resistance to abrasion because the main driving engaging parts are made of bearing steel and applying rolling friction.

-

5. Stable running: for most driving procedure, we adopt multi-teeth falling-in. Then the running will be stable with low noise.

-

6. Convenient dismounting:reasonable structure and design.

-

7. Strong overloading ability,anti-compact,suitable for frequently start and double-side rotation.

Specification

BWD BLD 2 Series 1:40 ratio cycloidal gearbox gear reducer for concrete transit mixer with TB support:

(please contact us for more types & model)

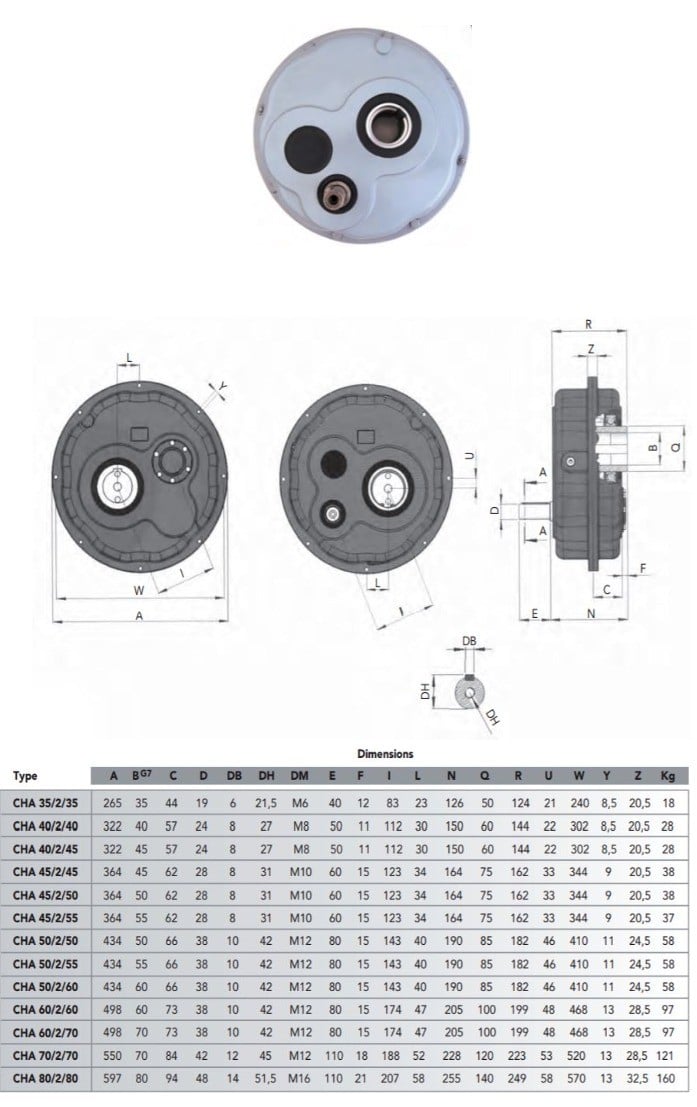

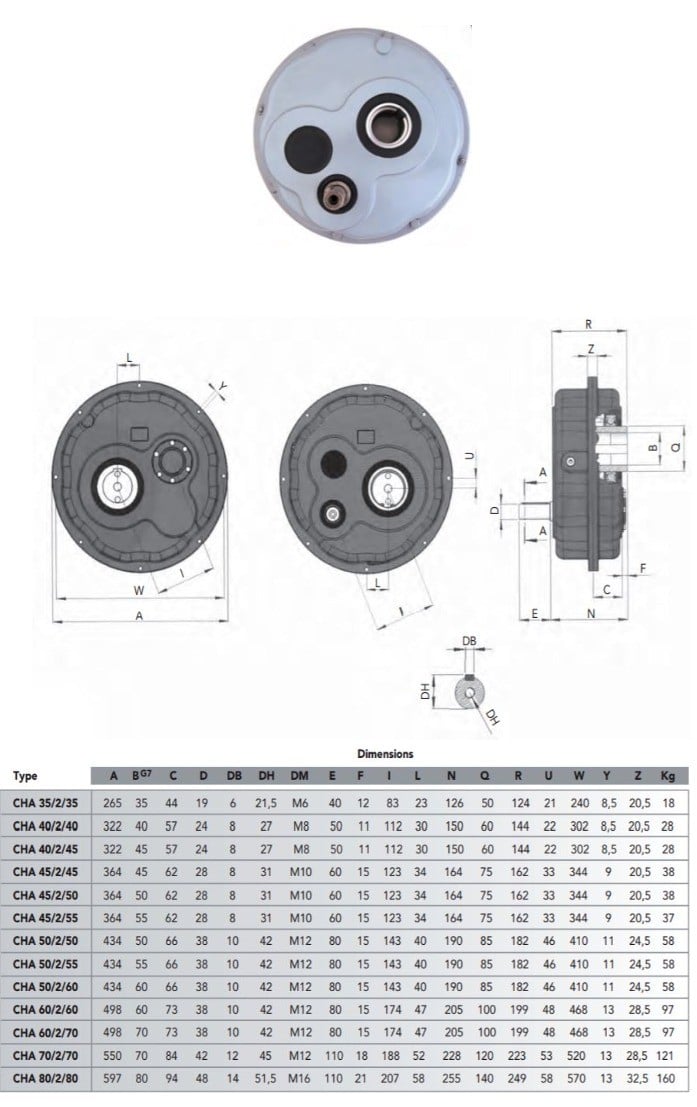

Mounting Diamensions

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.H B series standard industrial gear box reducer.Industrial Right Angle Transmission Gearbox price.Gearbox Manufacturer helical gear design gearbox with moderate price.Chinese Manufacture cycloid gearbox for iron and steel industry.BWD BLD 2 Series 1:40 ratio cycloidal gearbox gear reducer for concrete transit mixer with TB support.

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing blooming mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Technology

Chinese Gearbox Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.Industrial Right Angle Transmission Gearbox price.Gearbox Manufacturer helical gear design gearbox with moderate price. Chinese Manufacture cycloid gearbox for iron and steel industry. BWD BLD 2 Series 1:40 ratio cycloidal gearbox gear reducer for concrete transit mixer with TB support.

Our Services

BWD BLD 2 Series 1:40 ratio cycloidal gearbox gear reducer for concrete transit mixer with TB support:

Packaging & Shipping

BWD BLD 2 Series 1:40 ratio cycloidal gearbox gear reducer for concrete transit mixer with TB support:

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!