Product Description

Model Selection

ZD Leader has a wide range of micro motor production lines in the industry, including DC Motor, AC Motor, Brushless Motor, Planetary Gear Motor, Drum Motor, Planetary Gearbox, RV Reducer and Harmonic Gearbox etc. Through technical innovation and customization, we help you create outstanding application systems and provide flexible solutions for various industrial automation situations.

• Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

• Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

• On Your Need

We can modify standard products or customize them to meet your specific needs.

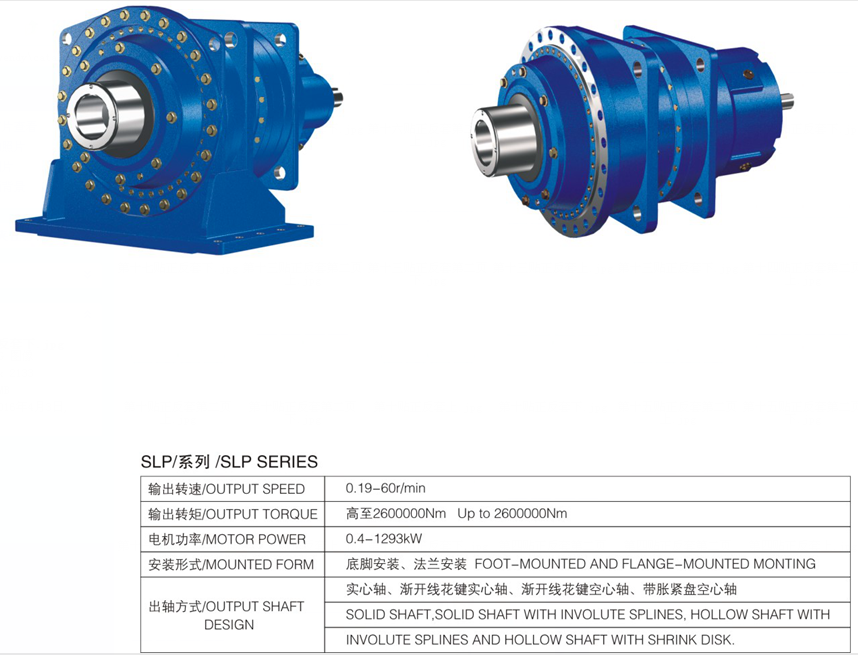

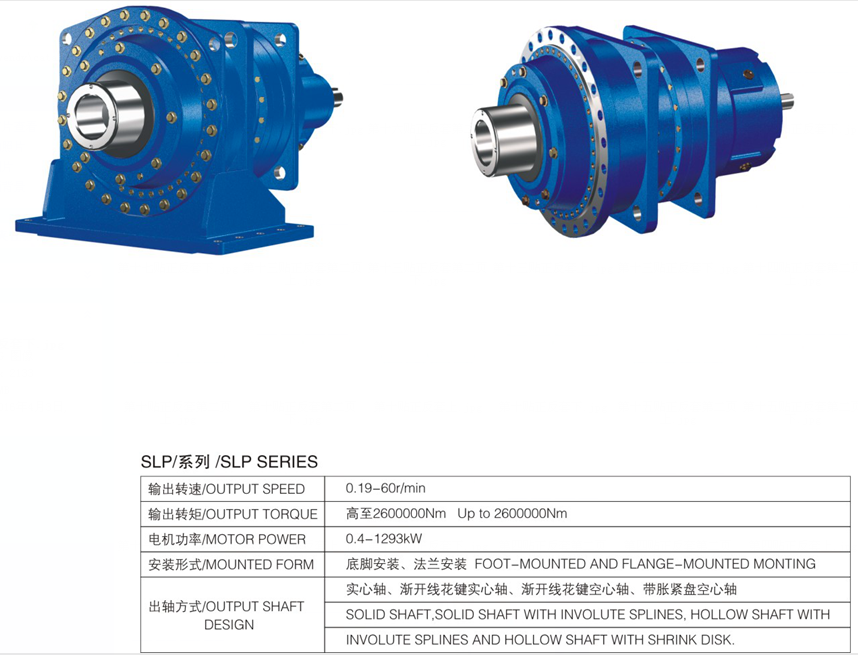

Product Parameters

Helical Gear Motor

| Mount Type | Horizontal / Vertical |

| MOTOR TYPE | Induction Motor |

| OUTPUT POWER | 100W / 200W / 400W / 750W / 1500W / 2200W / 3700W (Can Be Customized) |

| OUTPUT SHAFT | 18mm / 22mm / 28mm / 32mm / 40mm / 50mm; Round Shaft, D-Cut Shaft, Key-Way Shaft (Can Be Customized) |

| Voltage type | Single phase 110V50/60Hz, 220V/50/60Hz; Three phase 220-240/380-415V, 50/60Hz |

| Accessories | Electric Brake / Fan / Terminal Box |

| Gear Ratio | 3K-1800K |

Type Of Helical Gear Motor

Other Products

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Moving Machinery |

|---|---|

| Operating Speed: | Constant Speed |

| Power Source: | AC Motor |

| Casing Protection: | Closed Type |

| Number of Poles: | 4 |

| Certification: | ISO9001, CCC |

| Customization: |

Available

|

|

|---|

What are the maintenance requirements for gear motors, and how can longevity be maximized?

Gear motors, like any mechanical system, require regular maintenance to ensure optimal performance and longevity. Proper maintenance practices help prevent failures, minimize downtime, and extend the lifespan of gear motors. Here are some maintenance requirements for gear motors and ways to maximize their longevity:

1. Lubrication:

Regular lubrication is essential for gear motors to reduce friction, wear, and heat generation. The gears, bearings, and other moving parts should be properly lubricated according to the manufacturer’s recommendations. Lubricants should be selected based on the motor’s specifications and operating conditions. Regular inspection and replenishment of lubricants, as well as periodic oil or grease changes, should be performed to maintain optimal lubrication levels and ensure long-lasting performance.

2. Inspection and Cleaning:

Regular inspection and cleaning of gear motors are crucial for identifying any signs of wear, damage, or contamination. Inspecting the gears, bearings, shafts, and connections can help detect any abnormalities or misalignments. Cleaning the motor’s exterior and ventilation channels to remove dust, debris, or moisture buildup is also important in preventing malfunctions and maintaining proper cooling. Any loose or damaged components should be repaired or replaced promptly.

3. Temperature and Environmental Considerations:

Monitoring and controlling the temperature and environmental conditions surrounding gear motors can significantly impact their longevity. Excessive heat can degrade lubricants, damage insulation, and lead to premature component failure. Ensuring proper ventilation, heat dissipation, and avoiding overloading the motor can help manage temperature effectively. Similarly, protecting gear motors from moisture, dust, chemicals, and other environmental contaminants is vital to prevent corrosion and damage.

4. Load Monitoring and Optimization:

Monitoring and optimizing the load placed on gear motors can contribute to their longevity. Operating gear motors within their specified load and speed ranges helps prevent excessive stress, overheating, and premature wear. Avoiding sudden and frequent acceleration or deceleration, as well as preventing overloading or continuous operation near the motor’s maximum capacity, can extend its lifespan.

5. Alignment and Vibration Analysis:

Proper alignment of gear motor components, such as gears, couplings, and shafts, is crucial for smooth and efficient operation. Misalignment can lead to increased friction, noise, and premature wear. Regularly checking and adjusting alignment, as well as performing vibration analysis, can help identify any misalignment or excessive vibration that may indicate underlying issues. Addressing alignment and vibration problems promptly can prevent further damage and maximize the motor’s longevity.

6. Preventive Maintenance and Regular Inspections:

Implementing a preventive maintenance program is essential for gear motors. This includes establishing a schedule for routine inspections, lubrication, and cleaning, as well as conducting periodic performance tests and measurements. Following the manufacturer’s guidelines and recommendations for maintenance tasks, such as belt tension checks, bearing replacements, or gear inspections, can help identify and address potential issues before they escalate into major failures.

By adhering to these maintenance requirements and best practices, the longevity of gear motors can be maximized. Regular maintenance, proper lubrication, load optimization, temperature control, and timely repairs or replacements of worn components contribute to the reliable operation and extended lifespan of gear motors.

Can gear motors be used for precise positioning, and if so, what features enable this?

Yes, gear motors can be used for precise positioning in various applications. The combination of gear mechanisms and motor control features enables gear motors to achieve accurate and repeatable positioning. Here’s a detailed explanation of the features that enable gear motors to be used for precise positioning:

1. Gear Reduction:

One of the key features of gear motors is their ability to provide gear reduction. Gear reduction refers to the process of reducing the output speed of the motor while increasing the torque. By using the appropriate gear ratio, gear motors can achieve finer control over the rotational movement, allowing for more precise positioning. The gear reduction mechanism enables the motor to rotate at a slower speed while maintaining higher torque, resulting in improved accuracy and control.

2. High Resolution Encoders:

Many gear motors are equipped with high-resolution encoders. An encoder is a device that measures the position and speed of the motor shaft. High-resolution encoders provide precise feedback on the motor’s rotational position, allowing for accurate position control. The encoder signals are used in conjunction with motor control algorithms to ensure precise positioning by monitoring and adjusting the motor’s movement in real-time. The use of high-resolution encoders greatly enhances the gear motor’s ability to achieve precise and repeatable positioning.

3. Closed-Loop Control:

Gear motors with closed-loop control systems offer enhanced positioning capabilities. Closed-loop control involves continuously comparing the actual motor position (as measured by the encoder) with the desired position and making adjustments to minimize any position error. The closed-loop control system uses feedback from the encoder to adjust the motor’s speed, direction, and torque, ensuring accurate positioning even in the presence of external disturbances or variations in the load. Closed-loop control enables gear motors to actively correct for position errors and maintain precise positioning over time.

4. Stepper Motors:

Stepper motors are a type of gear motor that provides excellent precision and control for positioning applications. Stepper motors operate by converting electrical pulses into incremental steps of movement. Each step corresponds to a specific angular displacement, allowing precise positioning control. Stepper motors offer high step resolution, allowing for fine position adjustments. They are commonly used in applications that require precise positioning, such as robotics, 3D printers, and CNC machines.

5. Servo Motors:

Servo motors are another type of gear motor that excels in precise positioning tasks. Servo motors combine a motor, a feedback device (such as an encoder), and a closed-loop control system. They offer high torque, high speed, and excellent positional accuracy. Servo motors are capable of dynamically adjusting their speed and torque to maintain the desired position accurately. They are widely used in applications that require precise and responsive positioning, such as industrial automation, robotics, and camera pan-tilt systems.

6. Motion Control Algorithms:

Advanced motion control algorithms play a crucial role in enabling gear motors to achieve precise positioning. These algorithms, implemented in motor control systems or dedicated motion controllers, optimize the motor’s behavior to ensure accurate positioning. They take into account factors such as acceleration, deceleration, velocity profiling, and jerk control to achieve smooth and precise movements. Motion control algorithms enhance the gear motor’s ability to start, stop, and position accurately, reducing position errors and overshoot.

By leveraging gear reduction, high-resolution encoders, closed-loop control, stepper motors, servo motors, and motion control algorithms, gear motors can be effectively used for precise positioning in various applications. These features enable gear motors to achieve accurate and repeatable positioning, making them suitable for tasks that require precise control and reliable positioning performance.

In which industries are gear motors commonly used, and what are their primary applications?

Gear motors find widespread use in various industries due to their versatility, reliability, and ability to provide controlled mechanical power. They are employed in a wide range of applications that require precise power transmission and speed control. Here’s a detailed explanation of the industries where gear motors are commonly used and their primary applications:

1. Robotics and Automation:

Gear motors play a crucial role in robotics and automation industries. They are used in robotic arms, conveyor systems, automated assembly lines, and other robotic applications. Gear motors provide the required torque, speed control, and directional control necessary for the precise movements and operations of robots. They enable accurate positioning, gripping, and manipulation tasks in industrial and commercial automation settings.

2. Automotive Industry:

The automotive industry extensively utilizes gear motors in various applications. They are used in power windows, windshield wipers, HVAC systems, seat adjustment mechanisms, and many other automotive components. Gear motors provide the necessary torque and speed control for these systems, enabling smooth and efficient operation. Additionally, gear motors are also utilized in electric and hybrid vehicles for powertrain applications.

3. Manufacturing and Machinery:

Gear motors find wide application in the manufacturing and machinery sector. They are used in conveyor belts, packaging equipment, material handling systems, industrial mixers, and other machinery. Gear motors provide reliable power transmission, precise speed control, and torque amplification, ensuring efficient and synchronized operation of various manufacturing processes and machinery.

4. HVAC and Building Systems:

In heating, ventilation, and air conditioning (HVAC) systems, gear motors are commonly used in damper actuators, control valves, and fan systems. They enable precise control of airflow, temperature, and pressure, contributing to energy efficiency and comfort in buildings. Gear motors also find applications in automatic doors, blinds, and gate systems, providing reliable and controlled movement.

5. Marine and Offshore Industry:

Gear motors are extensively used in the marine and offshore industry, particularly in propulsion systems, winches, and cranes. They provide the required torque and speed control for various marine operations, including steering, anchor handling, cargo handling, and positioning equipment. Gear motors in marine applications are designed to withstand harsh environments and provide reliable performance under demanding conditions.

6. Renewable Energy Systems:

The renewable energy sector, including wind turbines and solar tracking systems, relies on gear motors for efficient power generation. Gear motors are used to adjust the rotor angle and position in wind turbines, optimizing their performance in different wind conditions. In solar tracking systems, gear motors enable the precise movement and alignment of solar panels to maximize sunlight capture and energy production.

7. Medical and Healthcare:

Gear motors have applications in the medical and healthcare industry, including in medical equipment, laboratory devices, and patient care systems. They are used in devices such as infusion pumps, ventilators, surgical robots, and diagnostic equipment. Gear motors provide precise control and smooth operation, ensuring accurate dosing, controlled movements, and reliable functionality in critical medical applications.

These are just a few examples of the industries where gear motors are commonly used. Their versatility and ability to provide controlled mechanical power make them indispensable in numerous applications requiring torque amplification, speed control, directional control, and load distribution. The reliable and efficient power transmission offered by gear motors contributes to the smooth and precise operation of machinery and systems in various industries.

editor by CX 2024-05-15

China Best Sales Stainless Steel Industrial CHINAMFG Wood Package Food Machinery AC Motor 50/60Hz vacuum pump and compressor

Product Description

What is applications use gear motor?

Electric gear motors are used in various applications that require for high output torque and low output rotation speed.

What is gear motor?

Gear motor is combined electric motor with gear reducer box.

Would you like to be GPG motor wholesaler,dealer,distributor,stockist?

GPG motor can improve your business.

Motorized drive roller motor is a new type of drive device,which is a conveyor drive where the motor,gear reducer and all moving parts are enclosed inside the drum.It is mainly used in fixed and movable type belt conveyor.

This roller drum motor can run under severe enviroment,such as water flow and spray,and erosion enviroment.Its protection grade is IP66.

If there are special requirement for the transmission system,such as space,low noise and high power,you can use our drum motor TMX.

The roller drum motor is widely used in the food processing,phamaceutical industry,packing machinery,aiport baggage handling system,meat processing industry,postal sorting and belt conveyor,etc.

Main benefits of belt conveyor drive roller drum motor

1.High mechanical efficiency highly reduces energy costs

2.Compact unit design enhances space utilization

3.No external moving parts increases operator safety

4.No maintenance reduces operating costs

We do also have DC brushless planetary geared roller drum motor to meet different application.

Should you any questions,please feel free to contact us directly.

Please leave message or send inquiry.I will be back to you asap.

| Rated power | 100W~5500W |

| Rated voltage | Single phase 110V, 220V,Three phase 220V,380V,440V |

| Pole Number | 2P,4P,6P,8P |

| Drum length | L≤850mm, 850mm < L≤1050mm,1050mm < L≤1250mm |

| Drum diameter | 80mm,113mm,138mm,165mm,216mm320mm,etc |

| Drum material | carbon steel,stainless steel |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Constant Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Protection Type |

| Number of Poles: | 4 |

| Samples: |

US$ 299/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What factors should be considered when selecting an AC motor for a particular application?

When selecting an AC motor for a particular application, several factors need to be considered to ensure the motor meets the requirements and performs optimally. Here are the key factors to consider:

- Power Requirements: Determine the power requirements of the application, including the required torque and speed. The motor should have adequate power output to meet the demands of the specific task. Consider factors such as starting torque, running torque, and speed range to ensure the motor can handle the load effectively.

- Motor Type: There are different types of AC motors, including induction motors, synchronous motors, and brushless DC motors. Each type has its own characteristics and advantages. Consider the application’s requirements and factors such as speed control, efficiency, and starting torque to determine the most suitable motor type.

- Environmental Conditions: Assess the environmental conditions in which the motor will operate. Factors such as temperature, humidity, dust, and vibration levels can impact motor performance and longevity. Choose a motor that is designed to withstand the specific environmental conditions of the application.

- Size and Space Constraints: Consider the available space for motor installation. Ensure that the physical dimensions of the motor, including its length, diameter, and mounting arrangement, are compatible with the available space. Additionally, consider the weight of the motor if it needs to be mounted or transported.

- Efficiency: Energy efficiency is an important consideration, as it can impact operational costs and environmental sustainability. Look for motors with high efficiency ratings, which indicate that they convert electrical energy into mechanical energy with minimal energy loss. Energy-efficient motors can lead to cost savings and reduced environmental impact over the motor’s lifespan.

- Control and Speed Requirements: Determine if the application requires precise speed control or if a fixed speed motor is sufficient. If variable speed control is needed, consider motors that can be easily controlled using variable frequency drives (VFDs) or other speed control mechanisms. For applications that require high-speed operation, select a motor that can achieve the desired speed range.

- Maintenance and Serviceability: Assess the maintenance requirements and serviceability of the motor. Consider factors such as the accessibility of motor components, ease of maintenance, availability of spare parts, and the manufacturer’s reputation for reliability and customer support. A motor that is easy to maintain and service can help minimize downtime and repair costs.

- Budget: Consider the budget constraints for the motor selection. Balance the desired features and performance with the available budget. In some cases, investing in a higher quality, more efficient motor upfront can lead to long-term cost savings due to reduced energy consumption and maintenance requirements.

By carefully considering these factors, it is possible to select an AC motor that aligns with the specific requirements of the application, ensuring optimal performance, efficiency, and reliability.

Can AC motors be used in renewable energy systems, such as wind turbines?

Yes, AC motors can be used in renewable energy systems, including wind turbines. In fact, AC motors are commonly employed in various applications within wind turbines due to their numerous advantages. Here’s a detailed explanation:

1. Generator: In a wind turbine system, the AC motor often functions as a generator. As the wind turbine blades rotate, they drive the rotor of the generator, which converts the mechanical energy of the wind into electrical energy. AC generators are commonly used in wind turbines due to their efficiency, reliability, and compatibility with power grid systems.

2. Variable Speed Control: AC motors offer the advantage of variable speed control, which is crucial for wind turbines. The wind speed is variable, and in order to maximize energy capture, the rotor speed needs to be adjusted accordingly. AC motors, when used as generators, can adjust their rotational speed with the changing wind conditions by modifying the frequency and voltage of the output electrical signal.

3. Efficiency: AC motors are known for their high efficiency, which is an important factor in renewable energy systems. Wind turbines aim to convert as much of the wind energy into electrical energy as possible. AC motors, especially those designed for high efficiency, can help maximize the overall energy conversion efficiency of the wind turbine system.

4. Grid Integration: AC motors are well-suited for grid integration in renewable energy systems. The electrical output from the AC generator can be easily synchronized with the grid frequency and voltage, allowing for seamless integration of the wind turbine system with the existing power grid infrastructure. This facilitates the efficient distribution of the generated electricity to consumers.

5. Control and Monitoring: AC motors offer advanced control and monitoring capabilities, which are essential for wind turbine systems. The electrical parameters, such as voltage, frequency, and power output, can be easily monitored and controlled in AC motor-based generators. This allows for real-time monitoring of the wind turbine performance, fault detection, and optimization of the power generation process.

6. Availability and Standardization: AC motors are widely available in various sizes and power ratings, making them readily accessible for wind turbine applications. They are also well-standardized, ensuring compatibility with other system components and facilitating maintenance, repair, and replacement activities.

It’s worth noting that while AC motors are commonly used in wind turbines, there are other types of generators and motor technologies utilized in specific wind turbine designs, such as permanent magnet synchronous generators (PMSGs) or doubly-fed induction generators (DFIGs). These alternatives offer their own advantages and may be preferred in certain wind turbine configurations.

In summary, AC motors can indeed be used in renewable energy systems, including wind turbines. Their efficiency, variable speed control, grid integration capabilities, and advanced control features make them a suitable choice for converting wind energy into electrical energy in a reliable and efficient manner.

What are the key advantages of using AC motors in industrial applications?

AC motors offer several key advantages that make them highly suitable for industrial applications. Here are some of the main advantages:

- Simple and Robust Design: AC motors, particularly induction motors, have a simple and robust design, making them reliable and easy to maintain. They consist of fewer moving parts compared to other types of motors, which reduces the likelihood of mechanical failure and the need for frequent maintenance.

- Wide Range of Power Ratings: AC motors are available in a wide range of power ratings, from small fractional horsepower motors to large industrial motors with several megawatts of power. This versatility allows for their application in various industrial processes and machinery, catering to different power requirements.

- High Efficiency: AC motors, especially modern designs, offer high levels of efficiency. They convert electrical energy into mechanical energy with minimal energy loss, resulting in cost savings and reduced environmental impact. High efficiency also means less heat generation, contributing to the longevity and reliability of the motor.

- Cost-Effectiveness: AC motors are generally cost-effective compared to other types of motors. Their simple construction and widespread use contribute to economies of scale, making them more affordable for industrial applications. Additionally, AC motors often have lower installation and maintenance costs due to their robust design and ease of operation.

- Flexible Speed Control: AC motors, particularly induction motors, offer various methods for speed control, allowing for precise adjustment of motor speed to meet specific industrial requirements. Speed control mechanisms such as variable frequency drives (VFDs) enable enhanced process control, energy savings, and improved productivity.

- Compatibility with AC Power Grid: AC motors are compatible with the standard AC power grid, which is widely available in industrial settings. This compatibility simplifies the motor installation process and eliminates the need for additional power conversion equipment, reducing complexity and cost.

- Adaptability to Various Environments: AC motors are designed to operate reliably in a wide range of environments. They can withstand variations in temperature, humidity, and dust levels commonly encountered in industrial settings. Additionally, AC motors can be equipped with protective enclosures to provide additional resistance to harsh conditions.

These advantages make AC motors a popular choice for industrial applications across various industries. Their simplicity, reliability, cost-effectiveness, energy efficiency, and speed control capabilities contribute to improved productivity, reduced operational costs, and enhanced process control in industrial settings.

editor by CX 2024-03-29

in Ansan Republic of Korea sales price shop near me near me shop factory supplier Wood Lathes Machinery China Factory Furniture 4 Heads Engraving Drilling for Door Cabinet manufacturer best Cost Custom Cheap wholesaler

With EPG manufacturer registered in far more than 70 nations around the world like The united states , Europe , Japan and so on, it has partners amid planet prime enterprises, these kinds of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so forth. Our products are used in a lot of fields. We will give greatest services and substantial high quality merchandise with all sincerity. EPT lathes EPTTry EPTT manufacturing unit furnishings four heads engraving drilling for door cupboard

Functions

one. EPT cnc router, four spindle heads function one by one particular, which is related with atc spindle cnc router, will save considerably time for altering tools and environment instruments, improves the operating performance and accuracy.

2. Multi head cnc router, when it has similar function with atc spindle cnc router, the expense is decrease.

three. EPT obligation metal tube welding structure, guarantee the EPTT service existence.

four. Vacuum absorption table can hold the processing substance tightly and very easily. Independent EPT block is suited for diverse sized supplies.

EPTnical parameter

| EPTT model | FM1325T4 4 head cnc router |

| Software | for home furniture, cupboard doorway, kitchen area, etc. |

| ATC sort | spindle changing by air cylinder |

| Spindle | four.5kw air cooled x 4pcs (18000rpm) |

| X Y Z vacation distance | 1300x2500x300 mm |

| Feeding peak | three hundred mm |

| Functioning table | EPT absorption desk with T-slots, incXiHu (West EPT) Dis.Hu (West EPT) Dis. seven.5kw EPT pump |

| XiHu (West EPT) Dis.hu (West EPT) Dis. rail | EPTTiwan sq. linear XiHu (West EPT) Dis.Hu (West EPT) Dis. rail |

| EPTT | X/Y aXiHu (West EPT) Dis.s – indirect tooth EPT rack, Z aXiHu (West EPT) Dis.s – ball screw |

| Drive motor | simple servo |

| Dust extraction | 3kw, double luggage |

| Lubrication | semi-automated kind |

| Resource sensor | incEPTTd |

| Vacation speed | 40000 mm/min |

| Positioning accuracy | .01 |

| EPTT technique | EPTEPTT |

| Operating voltage | AC380V, three period, fifty/60Hz (AC220V for optional) |

Principal configuration

Relevant Sector and resources

#Engraving, milling and slicing processing for wooden, mdf, acrylic, PVC, density boards, synthetic stones, organic EPT, plastics and metal sheets this sort of as copper and EPT and many others.

#EPT EPTT: cabinet doorways, picket doors, reliable woods, plates, antique furnishings, doors, home windows, desks and chairs.

#Decoration EPTT: EPTs, wave boards, massive-dimensions wall hangings, advertising boards and indication creating.

#Arts Crafts EPTT: Engrave on artificial stones, woods, EPTs, marbles, natural boards, double-shade boards and so on for attaining effects of exquisite patterns and characters.

Our Services for wooden cnc EPTT

Before sale:

We would alwaEPTTbe listed here to supply any details you need at the 1st time,and give expert ideas in accordance to your true wants for free

For the duration of sale:

We would deal with all the generation and shipping and delivery affairs,right after everything is all set,we would tell you every thing goes effectively right here

Right after sale:

1. We would provide EPT Model doing work handbook.

two. If you have any inquiries for the duration of making use of and mainXiHu (West EPT) Dis.Hu (West EPT) Dis.,our engineers who could sEPT very excellent EPT would answer you on the internet or by phone calls.

3. EPTT warranty is 1 calendar year. So if your EPTT has any accidental damages,we would offer parts for free.

four. If your EPTT has huge issues if by any opportunity,our engineers would arrive there to debug and correct.

5. Could be distant management if essential.

Packiing and XiHu (West EPT) Dis.Hu (West EPT) Dis.

1. Outdoors package deal: StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd maritime export plywood situation.

two. Interior package deal: A few layers in total EPTE pearl cotton movie PE stretchy movie.

three.EPTTroved bundle, significantly more sturdy and environmental defense.

4.We can also make bundle in accordance to your requests.

Delivery Element: Delivered in 25-thirty functioning daEPTTafter payment.

Our EPTT

EPTEPTTn Agency CNC EPT EPTT, Ltd is situated in EPTEPTTn metropolis, ZheJiang province. We are a professional and good reputation maker of CNC router (router cnc, cnc wooden router), laser engraving EPTT, CNC plasma cutter, laser chopping EPTT, laser marking EPTT in EPTT to the new and eXiHu (West EPT) Dis.sting customers that are EPT through the South The us, Center EPT, SouthEPT Asia, Africa, Europe and other counties of the world and the EPTTs has passed the EU CE certification

The aim of EPTEPTTn Organization CNC Router is to constantly update the approach, to help our consumers make the best quality and high precision merchandise.

EPTT in workshop

Other distinct sorts of cnc router EPTTs

FAQ

Concern one:How EPTT about the EPTT’s assure ?

Answer :two a long time

Concern 2:How about your following support ?

Response :EPTnical help by mobile phone, e-mail or MSN all around the clock.

Concern three: How can we set up the EPTT?

Reply :Welcoming EPT model handbook and operation online video CD disk.

Query four: How about the payment terms?

Solution:30% T/T for deposit, 70%T/T paid ahead of transport.

T/T, West EPT, Paypal

Issue 5: Do You Set up Shipment For The EPTTs?

Answer: Yes, expensive esteemed consumers, for FOB or CIF price tag, we will organize shipment for you.

For EXW price tag, consumers need to have to organize shipment by by themselves or their brokers.

High made in China – replacement parts – in Salta Argentina Precision Irrigation Machinery Worm Gear and Worm with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches. For much more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Requirements

– OEM services offered

– Outstanding quality at aggressive price

-Custom-made

We can provide OEM Provider for Gear Steel Castings, and those metal castings can be made in the following circumstances:

- Heat therapy: Normalized, Normalized and Tempered, Quenched and Tempered

- Machining: Rough machined, Semi-concluded machined, Finished machined

- Non-Damaging Screening: Magnetic Particle Testing, Ultrasonic Testing, Penetrant Tests

- Materials: Carbon Metal, Alloy Metal, fulfill ASTM, BS, DIN, NF, JIS, ISO common

- Personal Bodyweight: 500KG – 140MT

Specialized parameters:

|

Content: |

Carbon steel: Q235B,C45 1045,A3,40Cr, 1.7035/1.7045 41Cr4/42Gr4 ISO41Cr4 AISI/SAE/ASTM 5140 SCr440 /SCr440 20CrMnTi, 42CrMo 4140 SCM440 42CrMo4 40CrMnMo 4142 and so forth Stainless Steel: SS304 SS316 etc Copper/Brass, Aluminium,Cast iron,Nylon/plastic, etc. |

|

Production Processing |

Forging, Cutting, Hobbing, lathe machining, grinding, broaching, thread rolling, treatment on quenching, surface treatment/rust-proof treatment final inspection |

|

Heat treatment |

Hardening and Tempering, High Frequency Quenching, Hard teeth,Carburizing Quenching Teeth Quenching and so on. |

|

Surface treatment |

Galvanizing/Zinc Plating,Color Painting, Dacrotized, Black Anodic Treatment,Black Oxide. Spray Printing, Mirror Finish, Burnishing, Sand-blasting and so on according to Customers’ demand. |

|

Efficiency |

High precision, high wear resistance, low noise, smooth and steady, high strength |

|

Common |

Standard sprocket:DIN8187, DIN8188, ISO , ANSI , JIS,BS. Nonstandard sprockets as to customers’ Drawing or sample. |

|

Payment, |

T/T (thirty% deposit in advance, 70% balance before shipping). |

|

Mini order |

Minimum qty is 1000 pcs. |

|

Shipping |

20-30days after receive deposit or negotiable |

|

Packaging |

Inner plastic bag and outer carton box or customer requirement. |

Material: Our castings utilizing Electrical Arc or Induction Furnace sand Vacuum Degassing (if essential) are produced to ASTM, AISI, DIN, JIS, SAE or proprietary specifications

Good quality Manage: UT,MT,RT,PT,chemical composition take a look at,mechanical house examination,and many others.

Warmth Therapy: Normalize,Quenching,Tempering,Anealled.

Floor Treatment method: painting,plating,polishing,black oxide,clear anti-ru EPT oil.

Inspection: Besides our in-property inspecion, you could also decide on a third social gathering inspection.

Regular: ANSI,ASTM,ASME,API,JIS,DIN,BS,EN,KS,UNI,SABS,GOST.

Certificate: 1, Raw materials certification(materials chemical compositon)

2, Heat treatment sheet report

3, Dimension inspection report

4, EPT te EPT report

Packing: Seaworthy plywood packaged on stell pallets or as customer’s ask for

Delivery Day: Decided by the quantity and dimensions of merchandise. Normally we control the huge diameter rings’ delivery time in 5 months soon after we obtain your official purchase.

Powder Metallurgy Sintering is manufactured by bronze / iron / stainless steel powder, mold pressed under high strain and then sintered underneath higher temperature. It is widely utilized for electric powered equipments, electirc equipment, woven devices, chemical engineering machines, agricultural equipment, building & engineering equipment, automobile industry, etc.

Our Solutions

12 months or far more, and we provide leading quality and be EPT services constantly.

Organization Information

Yunfeng Powder Metallurgy Business have much more than 10years expertise in powder metallurgy sintered elements. We are familiar with the stringent needs of the automotive, aerospace, hardware, electricity resource, equipment industries.

Powder Metallurgy Elements help save your time and value!

OEM service factory precision steel ratchet gear with facet hole

| Name: | ratchet equipment |

| Model: | HKAA |

| Te EPT device: | hardness tester/pull and push drive tester/HEXGON model CMM from swiss |

| Application: | transmission parts |

| Colour: | black/silver/eco-friendly/gold |

| MOQ: | 10pcs |

| Processing: | cnc components/forging portion/hobbing components |

| Substance: | Moderate metal/ stainless metal/aluminum/steel alloy/plastic |

| Tolerance: | .01mm |

| Certificate: | ISO9001:2008 TS16949 |

Specialty EPT Manufactory!

Surface: customer requirement

Material: steel /stainless metal/ aluminum / brass / iron / zinc / alloy ,Any EPT content and dimension is dependent on customers’ demand.

Use: machinery / household furniture / toy / woodboard / wall

EPT approach: casting parts

Euipment: casting device

Screening products: projector

Tolerance:+/-.05MM

We are inclined to give with sample for good quality and perform tests.

We are ISO 9001: 2008 licensed organization.

We normally do bushiness, like this action:

| * You deliver us drawing or sample |

| * We have by way of task assessment |

| * We give you our style for your affirmation |

| * We make the sample and deliver it to you following you verified our design |

| * You confirm the sample then area an purchase and shell out us thirty% deposit |

| * We commence producing |

| * When the goods is completed, you spend us the balance after you verified photographs or tracking figures. |

We have extensively variety of design and style and manufacturing such as personalized cnc machining, cnc

machined parts, non-common equipment components, machined casting elements and precision turned

areas that the materia EPT of components elements are in metal, stainless steel, brass, aluminum

and plastic. In addition, we specialized in precision areas and components machining to

provide the electronics, automotive areas, astronautical parts, healthcare appliances and hand

resource industries.

if you have specific requirement about the components material, tolerance, process, therapy,

gear or take a look at, this kind of as seamless copper fin tubing, aluminum alloy 535 casting, and

glass-lined alloy casting, particular paint painting, 5 axis centers, 3D Coordinate

Measurement Equipment (CMM) te EPT … ju EPT truly feel free of charge to contact us, we will try our be EPT to

meet all your demands.

Item Particulars

1. Heat treament:carburizing and quenching

2. Area disposal:pressured shot-peening

three. Advantage:launched the substantial technological innovation from American and produce the fir EPT rank-highest good quality truck gear in China.

4. All varieties of gears, welded axle and synchronizer assembly for 11509C fuller/fa EPT sub-gearbox are available.

five. we can supply samples for inspection.

Our companies

Robust Machining & Warmth Treatment method Abilities

Rigid Quality Management

Broad Product Variety

14 years’ OEM experience

Customizing accessible

competitive value

| Design | on request, made with the buyer use | |

| Manufacture | current very first-class generation line | |

| Good quality handle | quality control office to guarantee good quality inspection report available |

|

| Packaging | risk-free and reputable packaging, on customer’s ask for |

If you failed to find the product you are fascinated in on our website. Make sure you truly feel cost-free to enable me know. We’re especially professional in production according to your sample or drawings.

Metal Spur Equipment For Digger

| Tooth Profile | Helical gear,involute |

| Force Angle | 20° |

| Kind

|

Mn=5,Z=fifty six, a=20°,β=11°58′, Xn=-.2, left hand

|

| Material | 20CrMnTi |

| Method

|

Forging+End Turning+Hobbing+Carburizing and Quenching+ Plain grinding +Interior Grinding+Teeth grinding |

| Application | EPT Machine |

| Brand name | JSSME or personalized |

| Solution Title | Metallic Spur Equipment For Digger |

Our Features

*1.Producer

*2.Stable Quality and Reasonable price

*3.Perfect quality inspection system

*4.Professional technical support and resolution team

Product Description

| A.Description of Spur gear energy transmission spur sintered gears This is crucial in all sorts of mechanical transmission areas, tooth floor speak to anxiety and friction below throughout procedure, tooth root bending stress are, at times to endure impact.So the equipment has good extensive mechanical homes, typically decide on solid steel blank. |

|||||||

| B. Our primary items line Material :C45 Rack & pinion module 1-10 Equipment Rack Employed for distinct devices and fields

|

|||||||

C.Material of equipment rack and pinion

|

|||||||

| D.parameter of gear rack and pinion | |||||||

| M1 | 10x10x1000 10x15x1000 | M1 | 15x15x250 15x15x500 | M3 | 30x30x250 30x30x500 | M5 | 50x50x250 50x50x500 |

| M1.5 | 15x15x1000 15x20x1000 | 15x15x1000 15x15x2000 | 30x30x1000 30x30x2000 | 50x50x1000 50x50x2000 | |||

| M2 | 20x20x1000 20x25x1000 | M1.5 | 17x17x250 17x17x500 | M6 | 60x60x250 60x60x500 | ||

| M2.5 | 25x25x1000 25x30x1000 | 17x17x1000 17x17x2000 | M4 | 22x22x250 22x22x500 | 60x60x1000 60x60x2000 | ||

| M3 | 30x30x1000 30x35x1000 | M2 | 20x20x250 20x20x500 | 22x22x1000 22x22x2000 | M8 | 80x80x250 80x80x500 | |

| M4 | 40x40x1000 40x45x1000 | 20x20x1000 20x20x2000 | M4 | 30x30x250 30x30x500 | 80x80x1000 80x80x2000 | ||

| M5 | 50x50x1000 50x55x1000 | M2.five | 25x25x250 25x25x500 | 30x30x1000 30x30x2000 | M10 | 100x100x250 100x100x500 | |

| M6 | 60x60x1000 60x65x1000 | 25x25x1000 25x25x2000 | M4 | 40x40x250 40x40x500 | 100x100x1000 100x100x2000 | ||

| M8 | 80x80x1000 | 40x40x1000 40x40x2000 | |||||

E.The major category of gear rack and pinion

|

|||||||

Company introduction

HangZhou Evon EPT CO.,L EPT is a manufacture of bearings, worm drivers, slewing bearings, gears, shaft and engineering parts. EVON bearings, worm motorists, slewing bearings, gears, shafts prove each day to be essential structural and link factors, they can be widely utilized in the lifting&transport machinery, mining equipment, building machinery, port hoisting machinery, port oil transfer equipment, onshore and offshore crane, excavator, concrete device, paper machine, plastic and rubber machine, weave equipment, cement plant, steel plant, electric electricity plant, wind energy generator, EPT construction and sector devices or tools and EPT large rotary units.

The merchandise produced by EVON EPT Co are mainly exported to the countries of the European Union, United states, the Center East, the South American, the Africa, Austrilian and Asia regions and the Russian Federation, in the process of cooperation with our clients, we have manufactured it a principle to build a lasting and rewarding partnership with our clients by offering successful support with the prime high quality and reducing the generation value.

Xihu (We EPT Lake) Dis.g for consistent commitment to the good quality of merchandise and consumer services, Evon EPT attaches excellent importance to research and development to make certain greater product good quality and service from its institution. The high quality of EVON items are based mostly on the excellent speciali EPT and specialized amount of constructors and professionals, extremely experienced operators, encounters manufacturing workers.

The company name: HangZhou Evon EPT Co.,ltd

Deal with: No 3 Lianmeng Highway, Xihu (We EPT Lake) Dis. Location, HangZhou City, ZheJiang Province, China

Tel: 0086~571-8822571/8822 0571 -64516701

Fax 0086~571-8822571/8822 0571 -64516702

Site:

The use of first tools manufacturer’s (OEM) element quantities or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our business and the outlined alternative components contained herein are not sponsored, accepted, or manufactured by the OEM.

Best China manufacturer & factory planetary in Amara Iraq gearbox drive power transmission gearbox for agricultural machinery high rpm gearboxplanetary gearbox redutor With high quality best price

we offer 1-quit solution for the purchase of mechanical chain,electricity transmission parts and pto shaft, agricultural gearboxes items in China.

Overview

Rapid Particulars

- Relevant Industries:

-

Lodges, Garment Stores, Creating Substance Outlets, Manufacturing Plant, Machinery Mend Stores, Foods & Beverage Manufacturing unit, Farms, Cafe, House Use, Retail, Meals Shop, Printing Stores, Power & Mining, Meals & Beverage Shops, AdverThe star tube is ideal for applications with high torque peaks that could be damaging to the other tube designs. The star tube with 6 get in touch with points is also the chosen decision when transmissions exceed 1600mm in duration and when the speed is a thousand rpm. AG sequence with splined tube The splined tube is suggested for extremely quick PTO shafts. The splined telescopic shaft enables bushing and splined couplings of only one hundred-120mm. The dimensions of the cross joints differ from 22mm diameter up to 48mm diameter and permit electrical power transmission of up to 250HP.tising Firm, Development performs

- Place of Origin:Zhejiang, China

- Brand name Name:

-

OEM

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

Up to 260000Nm

- Enter Pace:

-

750-1500rpm

- Output Pace:

-

.19-60rpm

It is smart to pay consideration to this element when the gear reducer output shaft is driven alternatively of being a driver. Bearing in thoughts that 1 of the features of this worm-equipment reducer is the fact that cannot be axle-driven by the output shaft (irreversibility), it is virtually impossible to fulfill overall irreversibility conditions, thanks to external factors this sort of as vibrations, etcÖ This is why, when the software needs complete irreversibility, it is a good idea to make use of external brakes with adequate electricity to avoid slipping.

- Certification:

-

ISO9001-2008

- Mount Situation:

-

Foot Mounted

- Bearing:

-

C & U

Offer Ability

- Supply Capability:

- 500 Unit/Models for each Thirty day period

Packaging & Delivery

- Packaging Particulars

- Common picket scenario

- Port

- Ningbo Port, Shanghai Port

On the web Customization

EPG is specialized in layout, producer and product sales of agricultural equipment and farm implements, which has an impartial import and export legal rights.

Specification

planetary gearbox velocity equipment increaser has the features of light excess weight, little volume, substantial transmission ratio, higher effectiveness, sleek rotation, lower noise and very good applicability.

1) Output velocity:.19~60r/min

two) Output torque: up to 260,000N.m

three) Motor energy: .4~1293kW

four) Mounted kind: foot-mounted ,flange-mounted

Primary software:

Mixers / Agitator,Roller presses,Conveyor drives,Shredders ,Filtration technological innovation,H2o remedy,Reactors,Journey drives,Feeder,Mill

Certifications

trade present

Packing

Packing Details : Standard carton/Pallet/Standard wooden scenario

Shipping and delivery Specifics : 15-30 operating times on payment

Top quality manage

Firm details

Supply

Get in touch with us

Best China manufacturer & factory china in Abeokuta Nigeria manufacturer factory OEM agricultural machinery equipment parts locking dust cover for JD cotton harvester machine With high quality best price

In 2008, it was awarded with “Countrywide Export Commodity Inspection-free of charge Business”.

Without having ample venting, higher temperatures increase inner pressure which can force lubricant earlier seal lips or enhance lip make contact with pressure, accelerating seal use and grooving on the seal journals.

Overview

Quick Particulars

- Warranty:

-

one.5 many years

- Relevant Industries:

-

Farms

- After Warranty Provider:

-

Video clip complex assist

- Neighborhood Service Location:

-

Canada, Turkey

- Showroom Location:

-

Egypt

- Online video outgoing-inspection:

-

Supplied

- Machinery Take a look at Report:

-

Provided

- Advertising Kind:

-

If you’re searching for a 540 PTO shaft, 540 to one thousand PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, appear no more. It’s critical to replace PTO areas that are worn or cracking before you have a key breakdown that could be costly and even unsafe. We have PTO push shafts as nicely as essential protect elements for your basic safety. Our Eurocardan elements contain a variety of types of clutches to increase the procedure of your electrical power consider-off technique. PTO shafts and equipment are an important portion of the more than 26,000 objects we carry for farm, shop, property and backyard garden.

New Product 2020

- Warranty of main components:

-

1.5 several years

- Main Elements:

-

Gearbox, Gear

- Important Offering Points:

-

Long Service Life

- Regional Provider Spot:

-

None

- Item Title:

-

H2o Distributor Cover

- Software:

-

Harverster Equipment

- MOQ:

-

ten

- Shipping time:

-

fifteen

- content:

-

stainless metal

- manufacturer:

-

mianyou

- Place of origin:

-

china

- merchandise No.:

-

SK279986

- warranty:

-

1.5 years

Source Potential

- Offer Ability:

- 200000 Piece/Parts for each Month

Packaging & Supply

- Packaging Information

- manufacturing unit OEM agricultural equipment gear elements locking dust cover for JD cotton harvester equipment

- Port

- Shanghai/Ninbo

-

Guide Time

: -

Quantity(Luggage) one – 5000 >5000 Est. Time(times) fifteen To be negotiated

On-line Customization

Adhering to “Survival by Good quality, Growth by Engineering & Credit history”, The business will continually enhance merchandise functionality to meet the growing customer demands in the rigorous style of work.

Solution Description

| Descriptions | manufacturing unit OEM agricultural equipment gear areas locking dust go over for JD cotton harvester device |

| Item nO. | SK279986 |

| Substance | stainless steel |

| Brand name | Mianyou |

| Area of Origin | ZheJiang China . EPG – 1 of the largest Agri-Machinery areas manufacturing facility in China /CN |

Item Exhibit

Relater Merchandise

Company Info

Logistics Shipping and delivery

1.Q:Are you manufacturer or trade company?Exactly where?

A:We are producer which situated in HangZhou,ZheJiang China . EPG – one particular of the biggest Agri-Machinery components factory in China .

2.Q:What is your phrases of payment ?

A: Payment=10000USD, 50% T/T in advance ,stability ahead of cargo. Irrepealable LC at sight for big order is substantial.

three.Q:What about shipping time?

A:The shipping and delivery time depends on solution and quantity .If you want to know the actual time. E mail us the amount,we will check the time for you.

four.Q:Is the web site price the closing price tag?

A:No. All the rates are negotiable based on the quantities.

five.Q:How will you control merchandise quality?

A:We strickly manage each element of creation and every product is inspected by our QC staff ahead of shipping and delivery. Furthermore,our manufacturing is abided by ISO 9001.

6.Q:When can you get the reply?

A:Any inquiries will be replied in 24 hours.Our income staff will try our best to assistance you.