Product Description

Product Description

Stepper motors, AC servo motors and brushless DC motors are avaiable to customized for the world, NEMA 11, 14, 16, 17, 23, 24, 34 stepper motor, 50W, 100W, 200W, 400W, 500W, 750W, 1000W, 1200W AC servo motor, and brushless DC motor are all included.

The derived products are widely used in ATM machines, digital scanners, stylus printers, plotters, slot machines, CD-ROM drivers, stage lighting, camera lenses, CNC machines, medical machines, 3D printers for industry and our life.

All the derived products of us can be customized for your needs.

Performance and parameters can be customized, just simply send your motor diagram or samples to us, the best price will be sent to you soon for your reference

Product Parameters

|

specifications: IHSS |

|||

|

Number of Phase |

2 |

Rotor Inertia |

1800g.cm² |

|

Step Angle |

1.8° |

Dielectric Strength |

500VDC |

|

Step Angle Accuracy |

±0.09° |

Insulation Resistance |

100MOHM (500VDC) |

|

Rated Current/phase |

6A |

Insulation Class (UL) |

B |

|

Resistance/phase |

0.43Ω±10% |

Temperature Rise Max |

80K |

|

Inductance/phase |

2.7MH±20% |

Radial Play |

Max 0.571mm (load 450g) |

|

Holding Torque |

4.5Nm |

Axial Play |

Max 0.075mm (load 920g) |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | NEMA Standard Stepper Motor |

| Samples: |

US$ 120/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How is the efficiency of a gear motor measured, and what factors can affect it?

The efficiency of a gear motor is a measure of how effectively it converts electrical input power into mechanical output power. It indicates the motor’s ability to minimize losses and maximize its energy conversion efficiency. The efficiency of a gear motor is typically measured using specific methods, and several factors can influence it. Here’s a detailed explanation:

Measuring Efficiency:

The efficiency of a gear motor is commonly measured by comparing the mechanical output power (Pout) to the electrical input power (Pin). The formula to calculate efficiency is:

Efficiency = (Pout / Pin) * 100%

The mechanical output power can be determined by measuring the torque (T) produced by the motor and the rotational speed (ω) at which it operates. The formula for mechanical power is:

Pout = T * ω

The electrical input power can be measured by monitoring the current (I) and voltage (V) supplied to the motor. The formula for electrical power is:

Pin = V * I

By substituting these values into the efficiency formula, the efficiency of the gear motor can be calculated as a percentage.

Factors Affecting Efficiency:

Several factors can influence the efficiency of a gear motor. Here are some notable factors:

- Friction and Mechanical Losses: Friction between moving parts, such as gears and bearings, can result in mechanical losses and reduce the overall efficiency of the gear motor. Minimizing friction through proper lubrication, high-quality components, and efficient design can help improve efficiency.

- Gearing Efficiency: The design and quality of the gears used in the gear motor can impact its efficiency. Gear trains can introduce mechanical losses due to gear meshing, misalignment, or backlash. Using well-designed gears with proper tooth profiles and minimizing gear train losses can improve efficiency.

- Motor Type and Construction: Different types of motors (e.g., brushed DC, brushless DC, AC induction) have varying efficiency characteristics. Motor construction, such as the quality of magnetic materials, winding resistance, and rotor design, can also affect efficiency. Choosing motors with higher efficiency ratings can improve overall gear motor efficiency.

- Electrical Losses: Electrical losses, such as resistive losses in motor windings or in the motor drive circuitry, can reduce efficiency. Minimizing resistance, optimizing motor drive electronics, and using efficient control algorithms can help mitigate electrical losses.

- Load Conditions: The operating conditions and load characteristics placed on the gear motor can impact its efficiency. Heavy loads, high speeds, or frequent acceleration and deceleration can increase losses and reduce efficiency. Matching the gear motor’s specifications to the application requirements and optimizing load conditions can improve efficiency.

- Temperature: Elevated temperatures can significantly affect the efficiency of a gear motor. Excessive heat can increase resistive losses, reduce lubrication effectiveness, and affect the magnetic properties of motor components. Proper cooling and thermal management techniques are essential to maintain optimal efficiency.

By considering these factors and implementing measures to minimize losses and optimize performance, the efficiency of a gear motor can be enhanced. Manufacturers often provide efficiency specifications for gear motors, allowing users to select motors that best meet their efficiency requirements for specific applications.

Can gear motors be used for precise positioning, and if so, what features enable this?

Yes, gear motors can be used for precise positioning in various applications. The combination of gear mechanisms and motor control features enables gear motors to achieve accurate and repeatable positioning. Here’s a detailed explanation of the features that enable gear motors to be used for precise positioning:

1. Gear Reduction:

One of the key features of gear motors is their ability to provide gear reduction. Gear reduction refers to the process of reducing the output speed of the motor while increasing the torque. By using the appropriate gear ratio, gear motors can achieve finer control over the rotational movement, allowing for more precise positioning. The gear reduction mechanism enables the motor to rotate at a slower speed while maintaining higher torque, resulting in improved accuracy and control.

2. High Resolution Encoders:

Many gear motors are equipped with high-resolution encoders. An encoder is a device that measures the position and speed of the motor shaft. High-resolution encoders provide precise feedback on the motor’s rotational position, allowing for accurate position control. The encoder signals are used in conjunction with motor control algorithms to ensure precise positioning by monitoring and adjusting the motor’s movement in real-time. The use of high-resolution encoders greatly enhances the gear motor’s ability to achieve precise and repeatable positioning.

3. Closed-Loop Control:

Gear motors with closed-loop control systems offer enhanced positioning capabilities. Closed-loop control involves continuously comparing the actual motor position (as measured by the encoder) with the desired position and making adjustments to minimize any position error. The closed-loop control system uses feedback from the encoder to adjust the motor’s speed, direction, and torque, ensuring accurate positioning even in the presence of external disturbances or variations in the load. Closed-loop control enables gear motors to actively correct for position errors and maintain precise positioning over time.

4. Stepper Motors:

Stepper motors are a type of gear motor that provides excellent precision and control for positioning applications. Stepper motors operate by converting electrical pulses into incremental steps of movement. Each step corresponds to a specific angular displacement, allowing precise positioning control. Stepper motors offer high step resolution, allowing for fine position adjustments. They are commonly used in applications that require precise positioning, such as robotics, 3D printers, and CNC machines.

5. Servo Motors:

Servo motors are another type of gear motor that excels in precise positioning tasks. Servo motors combine a motor, a feedback device (such as an encoder), and a closed-loop control system. They offer high torque, high speed, and excellent positional accuracy. Servo motors are capable of dynamically adjusting their speed and torque to maintain the desired position accurately. They are widely used in applications that require precise and responsive positioning, such as industrial automation, robotics, and camera pan-tilt systems.

6. Motion Control Algorithms:

Advanced motion control algorithms play a crucial role in enabling gear motors to achieve precise positioning. These algorithms, implemented in motor control systems or dedicated motion controllers, optimize the motor’s behavior to ensure accurate positioning. They take into account factors such as acceleration, deceleration, velocity profiling, and jerk control to achieve smooth and precise movements. Motion control algorithms enhance the gear motor’s ability to start, stop, and position accurately, reducing position errors and overshoot.

By leveraging gear reduction, high-resolution encoders, closed-loop control, stepper motors, servo motors, and motion control algorithms, gear motors can be effectively used for precise positioning in various applications. These features enable gear motors to achieve accurate and repeatable positioning, making them suitable for tasks that require precise control and reliable positioning performance.

How does the gearing mechanism in a gear motor contribute to torque and speed control?

The gearing mechanism in a gear motor plays a crucial role in controlling torque and speed. By utilizing different gear ratios and configurations, the gearing mechanism allows for precise manipulation of these parameters. Here’s a detailed explanation of how the gearing mechanism contributes to torque and speed control in a gear motor:

The gearing mechanism consists of multiple gears with varying sizes, tooth configurations, and arrangements. Each gear in the system engages with another gear, creating a mechanical connection. When the motor rotates, it drives the rotation of the first gear, which then transfers the motion to subsequent gears, ultimately resulting in the output shaft’s rotation.

Torque Control:

The gearing mechanism in a gear motor enables torque control through the principle of mechanical advantage. The gear system utilizes gears with different numbers of teeth, known as gear ratio, to adjust the torque output. When a smaller gear (pinion) engages with a larger gear (gear), the pinion rotates faster than the gear but exerts more force or torque. This results in torque amplification, allowing the gear motor to deliver higher torque at the output shaft while reducing the rotational speed. Conversely, if a larger gear engages with a smaller gear, torque reduction occurs, resulting in higher rotational speed at the output shaft.

By selecting the appropriate gear ratio, the gearing mechanism effectively adjusts the torque output of the gear motor to match the requirements of the application. This torque control capability is essential in applications that demand high torque for heavy lifting or overcoming resistance, as well as applications that require lower torque but higher rotational speed.

Speed Control:

The gearing mechanism also contributes to speed control in a gear motor. The gear ratio determines the relationship between the rotational speed of the input shaft (driven by the motor) and the output shaft. When a gear motor has a higher gear ratio (more teeth on the driven gear compared to the driving gear), it reduces the output speed while increasing the torque. Conversely, a lower gear ratio increases the output speed while reducing the torque.

By choosing the appropriate gear ratio, the gearing mechanism allows for precise speed control in a gear motor. This is particularly useful in applications that require specific speed ranges or variations, such as conveyor systems, robotic movements, or machinery that needs to operate at different speeds for different tasks. The speed control capability of the gearing mechanism enables the gear motor to match the desired speed requirements of the application accurately.

In summary, the gearing mechanism in a gear motor contributes to torque and speed control by utilizing different gear ratios and configurations. It enables torque amplification or reduction, depending on the gear arrangement, allowing the gear motor to deliver the required torque output. Additionally, the gear ratio also determines the relationship between the rotational speed of the input and output shafts, providing precise speed control. These torque and speed control capabilities make gear motors versatile and suitable for a wide range of applications in various industries.

editor by CX 2024-04-29

China Good quality AC Hypoid Geared Motor Right Angle Gearbox 220V 380V 1500W 1.5kw 2 HP AC Gear Motor for Sewing Machine with high quality

Product Description

AC Hypoid Geared Motor Right Angle Gearbox 220v 380v 1500w 1.5kw 2 hp AC Gear Motor For Sewing Machine

Products Description

| The following are the specifications that our company’s Right angle AC hypoid gear motors 1500W can achieved. You can also contact us to tell us the power, voltage, torque and other parameters you need. We can accept and customize. and You can also contact us for drawings and detailed parameters. | ||||

| Band name | Lunyee | |||

| Output Power | 1500W | |||

| Voltage | 220v 380v | |||

| Frequency | 50Hz 60Hz | |||

| Phase | 3-phase | |||

| Gear box | hypoid gear | |||

| Ratio | 5-60 | |||

| Output shaft type | hollow shaft CHINAMFG shaft | |||

| Output shaft axial | L axis(left) R(right) axis | |||

| Allowable torque | 17.49 N.m – 554 N.m | |||

| Insulation grade | F | |||

| Poles | 2 | |||

| Rated | Continued (except with brake) | |||

| Deceleration mode | Straight shaft: hyperbolic gear, helical gear | |||

| Installation direction | Horizontal, verical, inclined and so on, no restrictions on the installtion angle | |||

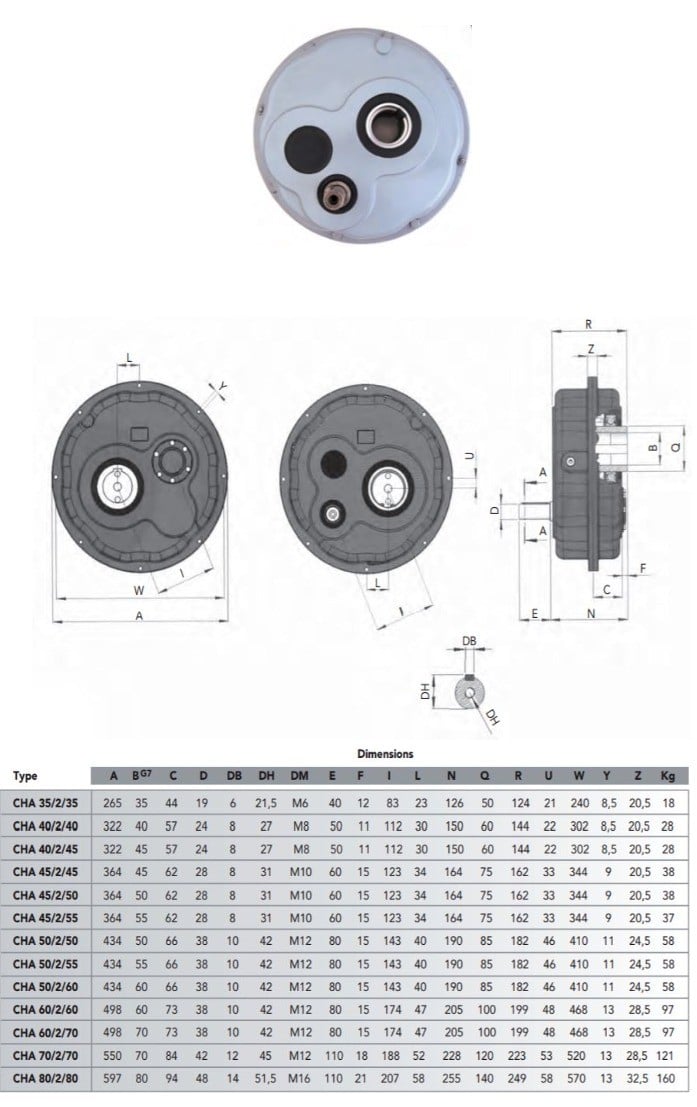

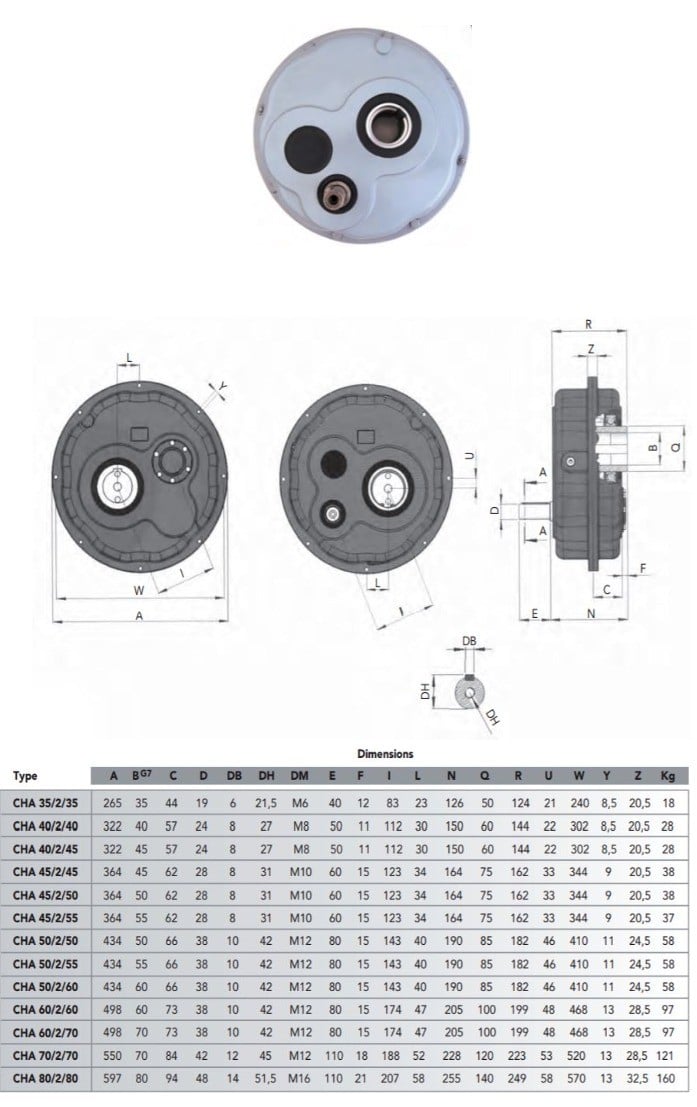

Hypoid geared motor Related parameters

product drawings

Product Features:

High efficiency

High torque Low speed

Low noise Long life Strong reliability

Running smoothly

Brushless environmental protection

Simple structure easy to use

Factory supplier best price

Suitable for extreme environments

Wide range of applications

product details

1.AC Gear Motor

Compact structure, good sealing performance, low noise, long life,low operating temperature Adjustable speed, reversible, CHINAMFG and reverse

2.All Copper Coil

All copper coil, fast heat dissipation, life is 10 times that of ordinary coil

3.High precision hard tooth surface

The gear has high precision, high hardness, anti-rust treatment, waterproof and quiet, long life

Application

AC gear motor widely used in Industrial equipment, machine tools, agricultural appliances, commercial office, medical equipment, household appliances, aviation and other fields. Such as treadmill, sewing machine, meat grinder , tortilla press maker, Apparel Machine, Textile Machine, Metal Coating Machinery, Pumps, Sprayers, heavy mine equipment, Packing Machine, nebulizer, table fan, Face Mask Machine, Rehabilitation Therapy Supplies, refrigerator, Air Purifiers, Fermenting Equipment. and many more.

Company Certifaction

About us:

ZheJiang CHINAMFG Industries Co., Limited. company, is the recognized top manufacturer of industrial humidification system inChina. Our factory has 3 large workshops, covering 3,000 square meter area. We have more than 100 employees, equip with professional R&D team, reliable workers and efficient sales service team. Green focus on research and development, manufacture, and sale of humidifying, air cooling, dedusting, dehumidifying and energy saving equipment. Our company is evolving as the change of customers’ needs, we are committed to developing and engineering new technology to best suit our customers’ demands. So far, we have got many patents on highly advanced and efficient humidifier designs.Working with Green, you will enjoy the latest and most advanced technology and kindest service.

Our Mine Product:

DC/AC motor, stepper motor, gearbox, CNC engraving machine, industrial humidifier.

Our Services:

Each of our products will undergo rigorous testing before leaving the factory. We will provide you with professional designs and solutions, high-quality products and high-quality services according to your needs. If you have any questions, please feel free to

contact us. We will serve you immediately.

Packing &Shipping

Inside : Plastic bags with Chemical Desiccant For Gear Housing

Middle : Individual Carton packaging Outside : Wooden Box

Shipment: TNT, DHL, UPS, FedEx,EMS etc.Or use the shipment your specified.

Strict product packaging ensures that the product is not damaged during transportation.

FAQ

Q1 Are you a manufacturer or a trading company?

We are a motor in China.

Q2 What’s your warranty?

One-year.

Q3 Can you give more discounts if more quantity and how many?

We can afford discounts and rate based on updated quantity.

Q4 Can you make OEM/ODM order?

Yes, we have rich experience on OEM/ODM order.

Q5 Delivery

Sample can be afforded within 5-7days and volume order can be finished within 15-20days.

Q6 About sample?

Available.

Q7 Which of payments you support?

T/T, L/C,PAYPAL, CREDIT CARD.

Q8 Which of transportations you support?

Sea, Air cargo, Train, DHL/FEDEX/UPS/TNT.

Q9 What you can do if we still have worry on your product?

We can afford sample for testing, if approval then negotiate cooperation later.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Closed Type |

| Number of Poles: | 4 |

| Samples: |

US$ 150/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are gear motors suitable for both heavy-duty industrial applications and smaller-scale uses?

Yes, gear motors are suitable for both heavy-duty industrial applications and smaller-scale uses. Their versatility and ability to provide torque multiplication make them valuable in a wide range of applications. Here’s a detailed explanation of why gear motors are suitable for both types of applications:

1. Heavy-Duty Industrial Applications:

Gear motors are commonly used in heavy-duty industrial applications due to their robustness and ability to handle high loads. Here are the reasons why they are suitable for such applications:

- Torque Multiplication: Gear motors are designed to provide high torque output, making them ideal for applications that require substantial force to move or operate heavy machinery, conveyors, or equipment.

- Load Handling: Industrial settings often involve heavy loads and demanding operating conditions. Gear motors, with their ability to handle high loads, are well-suited for tasks such as lifting, pulling, pushing, or driving heavy materials or equipment.

- Durability: Heavy-duty industrial applications require components that can withstand harsh environments, frequent use, and demanding operating conditions. Gear motors are typically constructed with durable materials and designed to withstand heavy vibrations, shock loads, and temperature variations.

- Speed Reduction: Many industrial processes require the reduction of motor speed to achieve the desired output speed. Gear motors offer precise speed reduction capabilities through gear ratios, allowing for optimal control and operation of machinery and equipment.

2. Smaller-Scale Uses:

While gear motors excel in heavy-duty industrial applications, they are also suitable for smaller-scale uses across various industries and applications. Here’s why gear motors are well-suited for smaller-scale uses:

- Compact Size: Gear motors are available in compact sizes, making them suitable for applications with limited space or small-scale machinery, devices, or appliances.

- Torque and Power Control: Even in smaller-scale applications, there may be a need for torque multiplication or precise power control. Gear motors can provide the necessary torque and power output for tasks such as precise positioning, controlling speed, or driving small loads.

- Versatility: Gear motors come in various configurations, such as parallel shaft, planetary, or worm gear designs, offering flexibility to match specific requirements. They can be adapted to different applications, including robotics, medical devices, automotive systems, home automation, and more.

- Efficiency: Gear motors are designed to be efficient, converting the electrical input power into mechanical output power with minimal losses. This efficiency is advantageous for smaller-scale applications where energy conservation and battery life are critical.

Overall, gear motors are highly versatile and suitable for both heavy-duty industrial applications and smaller-scale uses. Their ability to provide torque multiplication, handle high loads, offer precise speed control, and accommodate various sizes and configurations makes them a reliable choice in a wide range of applications. Whether it’s powering large industrial machinery or driving small-scale automation systems, gear motors provide the necessary torque, control, and durability required for efficient operation.

What is the significance of gear reduction in gear motors, and how does it affect efficiency?

Gear reduction plays a significant role in gear motors as it enables the motor to deliver higher torque while reducing the output speed. This feature has several important implications for gear motors, including enhanced power transmission, improved control, and potential trade-offs in terms of efficiency. Here’s a detailed explanation of the significance of gear reduction in gear motors and its effect on efficiency:

Significance of Gear Reduction:

1. Increased Torque: Gear reduction allows gear motors to generate higher torque output compared to a motor without gears. By reducing the rotational speed at the output shaft, gear reduction increases the mechanical advantage of the system. This increased torque is beneficial in applications that require high torque to overcome resistance, such as lifting heavy loads or driving machinery with high inertia.

2. Improved Control: Gear reduction enhances the control and precision of gear motors. By reducing the speed, gear reduction allows for finer control over the motor’s rotational movement. This is particularly important in applications that require precise positioning or accurate speed control. The gear reduction mechanism enables gear motors to achieve smoother and more controlled movements, reducing the risk of overshooting or undershooting the desired position.

3. Load Matching: Gear reduction helps match the motor’s power characteristics to the load requirements. Different applications have varying torque and speed requirements. Gear reduction allows the gear motor to achieve a better match between the motor’s power output and the specific requirements of the load. It enables the motor to operate closer to its peak efficiency by optimizing the torque-speed trade-off.

Effect on Efficiency:

While gear reduction offers several advantages, it can also affect the efficiency of gear motors. Here’s how gear reduction impacts efficiency:

1. Mechanical Efficiency: The gear reduction process introduces mechanical components such as gears, bearings, and lubrication systems. These components introduce additional friction and mechanical losses into the system. As a result, some energy is lost in the form of heat during the gear reduction process. The efficiency of the gear motor is influenced by the quality of the gears, the lubrication used, and the overall design of the gear system. Well-designed and properly maintained gear systems can minimize these losses and optimize mechanical efficiency.

2. System Efficiency: Gear reduction affects the overall system efficiency by impacting the motor’s electrical efficiency. In gear motors, the motor typically operates at higher speeds and lower torques compared to a direct-drive motor. The overall system efficiency takes into account both the electrical efficiency of the motor and the mechanical efficiency of the gear system. While gear reduction can increase the torque output, it also introduces additional losses due to increased mechanical complexity. Therefore, the overall system efficiency may be lower compared to a direct-drive motor for certain applications.

It’s important to note that the efficiency of gear motors is influenced by various factors beyond gear reduction, such as motor design, control systems, and operating conditions. The selection of high-quality gears, proper lubrication, and regular maintenance can help minimize losses and improve efficiency. Additionally, advancements in gear technology, such as the use of precision gears and improved lubricants, can contribute to higher overall efficiency in gear motors.

In summary, gear reduction is significant in gear motors as it provides increased torque, improved control, and better load matching. However, gear reduction can introduce mechanical losses and affect the overall efficiency of the system. Proper design, maintenance, and consideration of application requirements are essential to optimize the balance between torque, speed, and efficiency in gear motors.

Are there specific considerations for selecting the right gear motor for a particular application?

When selecting a gear motor for a specific application, several considerations need to be taken into account. The choice of the right gear motor is crucial to ensure optimal performance, efficiency, and reliability. Here’s a detailed explanation of the specific considerations for selecting the right gear motor for a particular application:

1. Torque Requirement:

The torque requirement of the application is a critical factor in gear motor selection. Determine the maximum torque that the gear motor needs to deliver to perform the required tasks. Consider both the starting torque (the torque required to initiate motion) and the operating torque (the torque required to sustain motion). Select a gear motor that can provide adequate torque to handle the load requirements of the application. It’s important to account for any potential torque spikes or variations during operation.

2. Speed Requirement:

Consider the desired speed range or specific speed requirements of the application. Determine the rotational speed (in RPM) that the gear motor needs to achieve to meet the application’s performance criteria. Select a gear motor with a suitable gear ratio that can achieve the desired speed at the output shaft. Ensure that the gear motor can maintain the required speed consistently and accurately throughout the operation.

3. Duty Cycle:

Evaluate the duty cycle of the application, which refers to the ratio of operating time to rest or idle time. Consider whether the application requires continuous operation or intermittent operation. Determine the duty cycle’s impact on the gear motor, including factors such as heat generation, cooling requirements, and potential wear and tear. Select a gear motor that is designed to handle the expected duty cycle and ensure long-term reliability and durability.

4. Environmental Factors:

Take into account the environmental conditions in which the gear motor will operate. Consider factors such as temperature extremes, humidity, dust, vibrations, and exposure to chemicals or corrosive substances. Choose a gear motor that is specifically designed to withstand and perform optimally under the anticipated environmental conditions. This may involve selecting gear motors with appropriate sealing, protective coatings, or materials that can resist corrosion and withstand harsh environments.

5. Efficiency and Power Requirements:

Consider the desired efficiency and power consumption of the gear motor. Evaluate the power supply available for the application and select a gear motor that operates within the specified voltage and current ranges. Assess the gear motor’s efficiency to ensure that it maximizes power transmission and minimizes wasted energy. Choosing an efficient gear motor can contribute to cost savings and reduced environmental impact.

6. Physical Constraints:

Assess the physical constraints of the application, including space limitations, mounting options, and integration requirements. Consider the size, dimensions, and weight of the gear motor to ensure it can be accommodated within the available space. Evaluate the mounting options and compatibility with the application’s mechanical structure. Additionally, consider any specific integration requirements, such as shaft dimensions, connectors, or interfaces that need to align with the application’s design.

7. Noise and Vibration:

Depending on the application, noise and vibration levels may be critical factors. Evaluate the acceptable noise and vibration levels for the application’s environment and operation. Choose a gear motor that is designed to minimize noise and vibration, such as those with helical gears or precision engineering. This is particularly important in applications that require quiet operation or where excessive noise and vibration may cause issues or discomfort.

By considering these specific factors when selecting a gear motor for a particular application, you can ensure that the chosen gear motor meets the performance requirements, operates efficiently, and provides reliable and consistent power transmission. It’s important to consult with gear motor manufacturers or experts to determine the most suitable gear motor based on the specific application’s needs.

editor by CX 2024-03-29

China Hot selling AC Universal Electric Gear Mini Motor 5430 for Eggbeater, Juicer Machine High Speed 24V 50W 100W 150W 10000rpm Universal Motor Ie 2 vacuum pump oil near me

Product Description

| BG 54 AC Motor | |

| Environmental Conditions | -20ºC~50ºC |

| Insulation Clase | B |

| Protection class | IP44 |

| Noise | ≤70dB |

| Number of phases | Single |

| Current | AC&DC |

| Lifespan | 1000-1500h |

| Electrical Specifications | |||||||||

| Model | RATED LOAD | NO LOAD | STALL | ||||||

| Voltage | Power |

Speed |

Torque | Current | Speed | Current | Torque | Current | |

| V | W | rpm | N.m | A | rpm | A | N.m | A | |

| BG AC5420 | 110 | 20 | 10000 | 0.02 | 0.36 | 17000 | 0.03 | 0.06 | 1.08 |

| BG AC5425 | 110 | 20 | 11000 | 0.016 | 0.36 | 18000 | 0.03 | 0.048 | 1.08 |

| BG AC5430 | 220 | 30 | 12000 | 0.571 | 0.3 | 20000 | 0.03 | 0.069 | 0.9 |

| We can also customize products according to customer requirements. | |||||||||

Established in 1994, HangZhou BG Motor Factory is a professional manufacturer of brushless DC motors, brushed DC motors, planetary gear motors, worm gear motors, Universal motors and AC motors. We have a plant area of 6000 square meters, multiple patent certificates, and we have the independent design and development capabilities and strong technical force, with an annual output of more than 1 million units. Since the beginning of its establishment, BG motor has focused on the overall solution of motors. We manufacture and design motors, provide professional customized services, respond quickly to customer needs, and actively help customers to solve problems. Our motor products are exported to 20 countries, including the United States, Germany, Italy, the United Kingdom, Poland, Slovenia, Switzerland, Sweden, Singapore, South Korea etc.

Our founder, Mr. Sun, has more than 40 years of experience in motor technology, and our other engineers also have more than 15 years of experience, and 60% of our staff have more than 10 years of experience, and we can assure you that the quality of our motors is top notch.

The products cover AGV, underwater robots, robots, sewing machine industry, automobiles, medical equipment, automatic doors, lifting equipment, industrial equipment and have a wide range of applications.

We strive for CHINAMFG in the quality of each product, and we are only a small and sophisticated manufacturer.

Our vision: Drive the world CHINAMFG and make life better!

Q:1.What kind of motors can you provide?

A:At present, we mainly produce brushless DC motors, brush DC motors, AC motors, Universal Motors; the power of the motor is less than 5000W, and the diameter of the motor is not more than 200mm;

Q:2.Can you send me a price list?

A:For all of our motors, they are customized based on different requirements like lifetime, noise,voltage,and shaft etc. The price also varies according to annual quantity. So it’s really difficult for us to provide a price list. If you can share your detailed requirements and annual quantity, we’ll see what offer we can provide.

Q:3.Can l get some samples?

A:It depends. If only a few samples for personal use or replacement, I am afraid it’ll be difficult for us to provide because all of our motors are custom made and no stock available if there are no further needs. If just sample testing before the official order and our MOQ,price and other terms are acceptable,we’d love to provide samples.

Q4:Can you provide OEM or ODM service?

A:Yes,OEM and ODM are both available, we have the professional R&D dept which can provide professional solutions for you.

Q5:Can l visit your factory before we place an order?

A:welcome to visit our factory,wear every pleased if we have the chance to know each other more.

Q:6.What’s the lead time for a regular order?

A:For orders, the standard lead time is 15-20 days and this time can be shorter or longer based on the different model,period and quantity.

| Application: | Universal |

|---|---|

| Speed: | 8000rpm-12000rpm |

| Number of Stator: | Single-Phase |

| Function: | Driving |

| Casing Protection: | Closed Type |

| Number of Poles: | 2 |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are there innovations or emerging technologies in the field of gear motor design?

Yes, there are several innovations and emerging technologies in the field of gear motor design. These advancements aim to improve the performance, efficiency, compactness, and reliability of gear motors. Here are some notable innovations and emerging technologies in gear motor design:

1. Miniaturization and Compact Design:

Advancements in manufacturing techniques and materials have enabled the miniaturization of gear motors without compromising their performance. Gear motors with compact designs are highly sought after in applications where space is limited, such as robotics, medical devices, and consumer electronics. Innovative approaches like micro-gear motors and integrated motor-gear units are being developed to achieve smaller form factors while maintaining high torque and efficiency.

2. High-Efficiency Gearing:

New gear designs focus on improving efficiency by reducing friction and mechanical losses. Advanced gear manufacturing techniques, such as precision machining and 3D printing, allow for the creation of intricate gear tooth profiles that optimize power transmission and minimize losses. Additionally, the use of high-performance materials, coatings, and lubricants helps reduce friction and wear, improving overall gear motor efficiency.

3. Magnetic Gearing:

Magnetic gearing is an emerging technology that replaces traditional mechanical gears with magnetic fields to transmit torque. It utilizes the interaction of permanent magnets to transfer power, eliminating the need for physical gear meshing. Magnetic gearing offers advantages such as high efficiency, low noise, compactness, and maintenance-free operation. While still being developed and refined, magnetic gearing holds promise for various applications, including gear motors.

4. Integrated Electronics and Controls:

Gear motor designs are incorporating integrated electronics and controls to enhance performance and functionality. Integrated motor drives and controllers simplify system integration, reduce wiring complexity, and allow for advanced control features. These integrated solutions offer precise speed and torque control, intelligent feedback mechanisms, and connectivity options for seamless integration into automation systems and IoT (Internet of Things) platforms.

5. Smart and Condition Monitoring Capabilities:

New gear motor designs incorporate smart features and condition monitoring capabilities to enable predictive maintenance and optimize performance. Integrated sensors and monitoring systems can detect abnormal operating conditions, track performance parameters, and provide real-time feedback for proactive maintenance and troubleshooting. This helps prevent unexpected failures, extend the lifespan of gear motors, and improve overall system reliability.

6. Energy-Efficient Motor Technologies:

Gear motor design is influenced by advancements in energy-efficient motor technologies. Brushless DC (BLDC) motors and synchronous reluctance motors (SynRM) are gaining popularity due to their higher efficiency, better power density, and improved controllability compared to traditional brushed DC and induction motors. These motor technologies, when combined with optimized gear designs, contribute to overall system energy savings and performance improvements.

These are just a few examples of the innovations and emerging technologies in gear motor design. The field is continuously evolving, driven by the need for more efficient, compact, and reliable motion control solutions in various industries. Gear motor manufacturers and researchers are actively exploring new materials, manufacturing techniques, control strategies, and system integration approaches to meet the evolving demands of modern applications.

How do gear motors compare to other types of motors in terms of power and efficiency?

Gear motors can be compared to other types of motors in terms of power output and efficiency. The choice of motor type depends on the specific application requirements, including the desired power level, efficiency, speed range, torque characteristics, and control capabilities. Here’s a detailed explanation of how gear motors compare to other types of motors in terms of power and efficiency:

1. Gear Motors:

Gear motors combine a motor with a gear mechanism to deliver increased torque output and improved control. The gear reduction enables gear motors to provide higher torque while reducing the output speed. This makes gear motors suitable for applications that require high torque, precise positioning, and controlled movements. However, the gear reduction process introduces mechanical losses, which can slightly reduce the overall efficiency of the system compared to direct-drive motors. The efficiency of gear motors can vary depending on factors such as gear quality, lubrication, and maintenance.

2. Direct-Drive Motors:

Direct-drive motors, also known as gearless or integrated motors, do not use a gear mechanism. They provide a direct connection between the motor and the load, eliminating the need for gear reduction. Direct-drive motors offer advantages such as high efficiency, low maintenance, and compact design. Since there are no gears involved, direct-drive motors experience fewer mechanical losses and can achieve higher overall efficiency compared to gear motors. However, direct-drive motors may have limitations in terms of torque output and speed range, and they may require more complex control systems to achieve precise positioning.

3. Stepper Motors:

Stepper motors are a type of gear motor that excels in precise positioning applications. They operate by converting electrical pulses into incremental steps of movement. Stepper motors offer excellent positional accuracy and control. They are capable of precise positioning and can hold a position without power. Stepper motors have relatively high torque at low speeds, making them suitable for applications that require precise control and positioning, such as robotics, 3D printers, and CNC machines. However, stepper motors may have lower overall efficiency compared to direct-drive motors due to the additional power required to overcome the detents between steps.

4. Servo Motors:

Servo motors are another type of gear motor known for their high torque, high speed, and excellent positional accuracy. Servo motors combine a motor, a feedback device (such as an encoder), and a closed-loop control system. They offer precise control over position, speed, and torque. Servo motors are widely used in applications that require accurate and responsive positioning, such as industrial automation, robotics, and camera pan-tilt systems. Servo motors can achieve high efficiency when properly optimized and controlled but may have slightly lower efficiency compared to direct-drive motors due to the additional complexity of the control system.

5. Efficiency Considerations:

When comparing power and efficiency among different motor types, it’s important to consider the specific requirements and operating conditions of the application. Factors such as load characteristics, speed range, duty cycle, and control requirements influence the overall efficiency of the motor system. While direct-drive motors generally offer higher efficiency due to the absence of mechanical losses from gears, gear motors can deliver higher torque output and enhanced control capabilities. The efficiency of gear motors can be optimized through proper gear selection, lubrication, and maintenance practices.

In summary, gear motors offer increased torque and improved control compared to direct-drive motors. However, gear reduction introduces mechanical losses that can slightly impact the overall efficiency of the system. Direct-drive motors, on the other hand, provide high efficiency and compact design but may have limitations in terms of torque and speed range. Stepper motors and servo motors, both types of gear motors, excel in precise positioning applications but may have slightly lower efficiency compared to direct-drive motors. The selection of the most suitable motor type depends on the specific requirements of the application, balancing power, efficiency, speed range, and control capabilities.

How does the gearing mechanism in a gear motor contribute to torque and speed control?

The gearing mechanism in a gear motor plays a crucial role in controlling torque and speed. By utilizing different gear ratios and configurations, the gearing mechanism allows for precise manipulation of these parameters. Here’s a detailed explanation of how the gearing mechanism contributes to torque and speed control in a gear motor:

The gearing mechanism consists of multiple gears with varying sizes, tooth configurations, and arrangements. Each gear in the system engages with another gear, creating a mechanical connection. When the motor rotates, it drives the rotation of the first gear, which then transfers the motion to subsequent gears, ultimately resulting in the output shaft’s rotation.

Torque Control:

The gearing mechanism in a gear motor enables torque control through the principle of mechanical advantage. The gear system utilizes gears with different numbers of teeth, known as gear ratio, to adjust the torque output. When a smaller gear (pinion) engages with a larger gear (gear), the pinion rotates faster than the gear but exerts more force or torque. This results in torque amplification, allowing the gear motor to deliver higher torque at the output shaft while reducing the rotational speed. Conversely, if a larger gear engages with a smaller gear, torque reduction occurs, resulting in higher rotational speed at the output shaft.

By selecting the appropriate gear ratio, the gearing mechanism effectively adjusts the torque output of the gear motor to match the requirements of the application. This torque control capability is essential in applications that demand high torque for heavy lifting or overcoming resistance, as well as applications that require lower torque but higher rotational speed.

Speed Control:

The gearing mechanism also contributes to speed control in a gear motor. The gear ratio determines the relationship between the rotational speed of the input shaft (driven by the motor) and the output shaft. When a gear motor has a higher gear ratio (more teeth on the driven gear compared to the driving gear), it reduces the output speed while increasing the torque. Conversely, a lower gear ratio increases the output speed while reducing the torque.

By choosing the appropriate gear ratio, the gearing mechanism allows for precise speed control in a gear motor. This is particularly useful in applications that require specific speed ranges or variations, such as conveyor systems, robotic movements, or machinery that needs to operate at different speeds for different tasks. The speed control capability of the gearing mechanism enables the gear motor to match the desired speed requirements of the application accurately.

In summary, the gearing mechanism in a gear motor contributes to torque and speed control by utilizing different gear ratios and configurations. It enables torque amplification or reduction, depending on the gear arrangement, allowing the gear motor to deliver the required torque output. Additionally, the gear ratio also determines the relationship between the rotational speed of the input and output shafts, providing precise speed control. These torque and speed control capabilities make gear motors versatile and suitable for a wide range of applications in various industries.

editor by CX 2023-11-17

in Siliguri India sales price shop near me near me shop factory supplier AC Hypoid Geared Motor Right Angle Gearbox 220V 380V 1500W 1.5kw 2 HP AC Gear Motor for Sewing Machine manufacturer best Cost Custom Cheap wholesaler

“We are constantly serving our clients with our best products.” If you are fascinated in any of our goods or would like to discuss a prospective purchase, make sure you truly feel free to contact us. In this way, our items have ongoing to obtain marketplace acceptance and clients gratification more than the previous couple of several years. AC Hypoid Geared Motor RigEPT Angle EPT 220v 380v 1500w 1.5kw two hp AC Equipment Motor For Stitching EPT

Items Description

| The pursuing are the specs that our company’s RigEPT angle AC hypoid equipment motors 1500W can attained. You can also make contact with us to tell us the EPT, voltage, torque and other parameters you need. We can accept and customize. and You can also speak to us for drawings and comprehensive parameters. | ||||

| EPTand title | EPT | |||

| Output EPT | 1500W | |||

| Voltage | 220v 380v | |||

| Frequency | 50Hz 60Hz | |||

| Phase | 3-stage | |||

| Gear box | hypoid gear | |||

| Ratio | 5-sixty | |||

| Output shaft variety | hollow shaft reliable shaft | |||

| Output shaft aXiHu (West Lake) Dis.al | L aXiHu (West Lake) Dis.s(left) R(right) aXiHu (West Lake) Dis.s | |||

| Allowable torque | seventeen.forty nine N.m – 554 N.m | |||

| Insulation grade | F | |||

| Poles | two | |||

| Rated | Continued (besides with brake) | |||

| Deceleration method | StraigEPT shaft: hyperEPTc gear, helical equipment | |||

| Set up course | Horizontal, verical, inclined and so on, no constraints on the installtion angle | |||

Hypoid geared motor Related parameters

merchandise drawings

Merchandise Characteristics:

Higher efficiency

High torque Minimal velocity

Reduced sound EPT life Sturdy reliability

Working smoothly

EPTrushless environmental security

Easy construction simple to use

Manufacturing unit provider very best price

Ideal for severe environments

Extensive assortment of purposes

merchandise details

1.AC Equipment Motor

Compact framework, good sealing functionality, minimal sound, EPT daily life,reduced working temperature Adjustable pace, reversible, EPT and reverse

2.All Copper Coil

All copper coil, quick warmth dissipation, life is 10 occasions that of ordinary coil

3.Substantial precision tough tooth surface

The equipment has substantial precision, high hardness, anti-rust therapy, watertight and peaceful, EPT daily life

Software

AC gear motor extensively utilised in EPT tools, EPT resources, agricultural appliances, business office, health care equipment, EPT appliances, aviation and other fields. Such as treadmill, stitching EPT, meat grinEPT, tortilla press maker, Clothing EPT, Textile EPT, Metallic Coating EPTry, Pumps, Sprayers, heavy mine gear, EPT EPT, nebulizer, desk fan, Encounter Mask EPT, Rehabilitation Therapy Provides, fridge, Air Purifiers, Fermenting Tools. and numerous more.

Company Certifaction

About us:

ZheJiang EPT EPT Co., Constrained. firm, is the regarded best maker of EPT humidification technique inEPT. Our manufacturing facility has 3 huge workshops, covering three,000 sq. meter region. We have more than one hundred employees, equip with skilled R ampD crew, reliable workers and efficient sales provider team. Inexperienced target on study and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment, manufacture, and sale of humidifying, air cooling, dedusting, dehumidifying and energy preserving products. Our organization is evolving as the change of customers’ wants, we are fully commited to deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ing and engineering new EPT to ideal go well with our customers’ needs. So far, we have received many patents on extremely innovative and efficient humidifier styles.Doing work with Green, you will enEPT the most recent and most advanced EPT and kindest support.

Our Mine Solution:

DC/AC motor, stepper motor, EPT, CNC engraving EPT, EPT humidifier.

Our Companies:

Each and every of our goods will endure demanding screening prior to leaving the factory. We will give you with professional types and answers, high-good quality merchandise and substantial-quality companies according to your wants. If you have any inquiries, please really feel free to

make contact with us. We will provide you right away.

EPT ampShipping

Inside of : Plastic luggage with Chemical Desiccant For Equipment Housing

Middle : Individual Carton EPT Exterior : Wooden EPTox

Shipment: TNT, DHL, UPS, FedEx,EMS and so on.Or use the cargo your specified.

Stringent solution EPT guarantees that the merchandise is not ruined for the duration of transportation.

FAQ

Q1 Are you a maker or a buying and selling organization?

We are a motor in EPT.

Q2 What is actually your warranty?

A single-12 months.

Q3 Can you give much more special discounts if far more amount and how numerous?

We can afford discounts and charge dependent on current amount.

This autumn Can you make OEM/ODM order?

Sure, we have rich knowledge on OEM/ODM purchase.

Q5 Supply

Sample can be afforded inside five-7daEPTand volume orEPTcan be concluded inside of fifteen-20days.

Q6 About sample?

Offered.

Q7 Which of payments you help?

T/T, L/C,PAYPAL, Credit history CARD.

Q8 Which of transportations you assist?

Sea, Air cargo, Prepare, DHL/FEDEX/UPS/TNT.

Q9 What you can do if we nevertheless have be concerned on your solution?

We can afford sample for testing, if acceptance then negotiate cooperation later on.

in Depok Indonesia sales price shop near me near me shop factory supplier 2 2.5rpm Tdy 50 Synchronous AC Gear Motor for Oven manufacturer best Cost Custom Cheap wholesaler

EPG was awarded with “renowned item of Zhejiang Province” and “famous model of Zhejiang Province”. In 2008, it was awarded with “Countrywide Export Commodity Inspection-totally free Company”. we provide chromed bar and tubes for hydualic and pheumatic cylinders. micro gear Motor for swing admirer/oven

1. Stator dimensions is optional

2. Safe, reputable, minimal sound, excellent starting up, EPT daily life

3. Strong EPT

Rated voltage 110~120V/220~240V-fifty/60Hz

Normal utilised: Exhaust enthusiast, air purifier, micro-oven, fan, induction cooker, fridge, pump, heater, hood oven, blwer, air conditioner, Heater EPTs, dehumidifiers

Thermal protector with one shot fuse or multi shot fuse

| 50SM40 | |||||||||||||||||||

| Software:-House Appliance | |||||||||||||||||||

| – Roaster | |||||||||||||||||||

| -Electrical Andiron | |||||||||||||||||||

| – Keep track of Products | |||||||||||||||||||

|

Rated Voltage | Rated Frequency | Speed | No-load Present | No-load EPT | Output Torque | Beginning Voltage | Temperatuer | |||||||||||

| (V) | (Hz) | (RPM) | (mA) | (W) | (kgf.cm) | (V) | Rising | ||||||||||||

| (K) | |||||||||||||||||||

| 50SM40 | 24 | 15 | 15 | le250 | le7 | ge2 | le20 | le75 | |||||||||||

|

|

|||||||||||||||||||

|

24 | 20 | twenty | le250 | le7 | ge1.five | le20 | le75 | |||||||||||

|

one hundred ten/one hundred twenty | fifty/sixty | eleven.five/13.eight | le60 | le7 | ge7 | le96 | le75 | |||||||||||

|

one hundred ten/a hundred and twenty | fifty/sixty | eleven.7/fourteen | le60 | le7 | ge6 | le96 | le75 | |||||||||||

| 50SM40 | one hundred ten/one hundred twenty | fifty/60 | fifty six | le35 | le7 | ge8 | le96 | le75 | |||||||||||

|

|

|||||||||||||||||||

|

220/240 | fifty/60 | fifty six | le35 | le7 | ge8 | le176 | le75 | |||||||||||

|

220/240 | 50/60 | 33.3/forty | le35 | le7 | ge2.five | le176 | le75 | |||||||||||

|

220/240 | 50/sixty | 11.5/13.8 | le35 | le7 | ge8 | le176 | le75 | |||||||||||

| 50SM40 | 220/240 | fifty/sixty | eleven.7/fourteen | le35 | le7 | ge6 | le176 | le75 | |||||||||||

AEPTOUT US

Ritscher team was established up in 2006.we alwaEPTfocus on micro-motors for EPT electrical equipment and sector equipment since placing up.at the moment we have two expert micro-motor factories in EPT which severally found in HangZhou town and HangZhou city.it has an location of 25,000 square meters EPTs and much more than 300 employees, yearly output is three million pcs and has five million pcs once-a-year producing potential.right after numerous several years deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment,we had created a great popularity in the market and received more and a lot more customers’ EPT in the world.

We started out from shaded pole motors at commencing, up to now,our merchandise incEPTd of shaded pole motors,synchronous motors,stepping motors ,capacitor motors, EPTLDC motors, DC motors and compressors. Our product are commonly used for making fridges, freezers, micro-wave ovens, air warmers, air exhausters, ventilators,ovens, air filter, therapeutic massage EPTs and many other equipments.

As a realiable top quality guaranty,Ritscher has full R ampD departement,QC office,generating division,acquire department and so forth. has perfect generating products like Aluminum diecasting, Zinc diecasting, Sheet metallic stamping, Plastic injection molding and many others. also examination/ detection gadget like multiplex temp measuring gadget, functionality parameter inspection unit, Phenol peptide answer pinhole tester,Anechoic space and so on.

Endeavoring to supply the ideal product and provider to buyers,we alwaEPTdo the most work to become an outstXiHu (West Lake) Dis.Hu (West Lake) Dis. maker of micro motors.

Ritscher is alwaEPTwilling to set up sincere enterprise romantic relationship with friends from all over the globe.

Welcome make contact with with us!

EPTke ritscher ,enEPT contemporary life!

Our organization FAQ for you

(1) Q: What type motors you can give?

A:For now,we mainly give Kitchen Hood Motor,DC Motor,Gear Motor,Fan Motor Refrigerator Motor,Hair Dryer Motor EPTlenEPTMotor Mixer Motor,

Shade Pole Motor,Capacitor Motor,EPTLDC Motor PMDC Motor,Synchronous Motor,Stepping Motor and so on.

(two) Q: Is it achievable to visit your manufacturing unit

A: Confident. EPTut you should kindly hold us posted a handful of daEPTEPT. We need to have to check our

plan to see if we are obtainable then.

(three) Q: Can I get some samples

A: It relies upon. If only a handful of samples for individual use or substitute, I am scared it will

be challenging for us to supply, due to the fact all of our motors are EPT and no stock

obtainable if there is no even more wants. If just sample tests just before the formal orEPTand

our MOQ, price and other phrases are suitable, we would love to supply samples.

(four) Q: Is there a MOQ for your motors?

A: Of course. The MOQ is in between a thousand~10,000pcs for diverse versions soon after sample approval.

EPTut it truly is also alright for us to take smaller heaps like a number of dozens, hundreds or 1000’s

For the initial 3 orders after sample approval.For samples, there is no MOQ prerequisite. EPTut the significantly less the far better (like no much more than 5pcs) on condition that the amount is sufficient in scenario any change

in Boston United States sales price shop near me near me shop factory supplier Best 90 Degree Gear Drive Box, Gearboxes One to One 4 Way, 2 to 1 Gear Reducers Right Angle Price manufacturer best Cost Custom Cheap wholesaler

Our product range also addresses locking assemblies (clamping components/locking unit), taper bushes, QD bushes, bolt-on hubs, torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod finishes and yokes. Complete use has been made of all varieties of superior strategies and technological innovation to attain excelsior producing. If you need to have any information or samples, remember to speak to us and you will have our before long reply.

We are professional ideal ninety degree equipment push box, EPTes 1 to one 4 way, two to 1 equipment EPTs rigEPT angle manufacturers and suppliers from EPT. All90 degree gear travel box, EPTes one to one four way, 2 to one gear EPTs rigEPT angle will be examined and inspection studies just before goods shipment.

JTP Sequence Cubic EPTl EPT

EPT JTP series cubic EPTl EPT is also recognized as cubic rigEPT angle miter EPT, cubic ninety diploma EPTl EPT, cubic miter EPTl equipment box, or cubic spiral EPTl equipment EPTs. JTP series cubic EPTl EPT is a correct-angle shaft variety equipment box of spiral EPTl gears for EPT apps with large EPT capability, high efficiency and high effectiveness. 1:1, 1.five:one, two:one, three:one, 4:one and 5:1 equipment ratios as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd. two way(a single input one output), 3 way(one particular enter two output, or two input a single output), four way(two enter two output) generate shafts as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd. Sound shaft as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd, customize hollow shaft or motor flange to bolt an IEC motor flange. MaXiHu (West Lake) Dis.mum torque 1299N.m. MaXiHu (West Lake) Dis.mum enter and output pace 1450RPM. There are 8 models: JTP65 mini cubic EPTl EPT, JTP90 cubic EPTl EPT, JTP110 cubic EPTl EPT, JTP140 cubic EPTl EPT, JTP170 cubic EPTl EPT, JTP210 cubic EPTl EPT, JTP240 cubic EPTl EPT and JTP280 cubic EPTl EPT.

| JTP65 Mini Cubic EPTl EPT 1. EPTl equipment ratio one:one two. strong generate shafts diameter12mm 3. sound enter and output shaft shafts 4. 2 way, three way, four way EPT five. input EPT maXiHu (West Lake) Dis.mum 1.8Kw six. generate torque maXiHu (West Lake) Dis.mum 13.5Nm seven. maXiHu (West Lake) Dis.mum enter 1500rpm |

JTP90 Cubic EPTl EPT one. equipment ratios one:1, 1.five:1, 2:1, three:one, 4:1 5:one two. cubic, 6 mount positions, EPT mount three. solid shaft, hollow shaft, motor flange four. two way, 3 way, 4 way EPT five. enter EPT maXiHu (West Lake) Dis.mum 6Kw six. drive torque maXiHu (West Lake) Dis.mum forty three.3Nm 7. maXiHu (West Lake) Dis.mum input 1500rpm |

JTP110 Cubic EPTl EPT 1. gear ratios 1:one, one.five:1, 2:1, 3:1, 4:one 5:one two. cubic, six mount positions, EPT mount 3. sound shaft, hollow shaft, motor flange 4. 2 way, 3 way, 4 way EPT five. input EPT maXiHu (West Lake) Dis.mum 11Kw six. drive torque maXiHu (West Lake) Dis.mum seventy eight.3Nm seven. maXiHu (West Lake) Dis.mum input 1500rpm |

| JTP140 Cubic EPTl EPT one. gear ratios one:1, 1.5:one, 2:1, three:one, 4:1 five:1 2. cubic, 6 mount positions, EPT mount three. strong shaft, hollow shaft, motor flange 4. two way, three way, four way EPT five. input EPT maXiHu (West Lake) Dis.mum 23. 9Kw six. travel torque maXiHu (West Lake) Dis.mum 170Nm seven. maXiHu (West Lake) Dis.mum enter 1500rpm |

JTP170 Cubic EPTl EPT 1. equipment ratios one:one, 1.five:one, two:1, three:1, 4:1 five:1 two. cubic, six mount positions, EPT mount three. sound shaft, hollow shaft, motor flange four. 2 way, three way, 4 way EPT 5. input EPT maXiHu (West Lake) Dis.mum 39.2Kw six. travel torque maXiHu (West Lake) Dis.mum 290Nm 7. maXiHu (West Lake) Dis.mum enter 1500rpm |

JTP210 Cubic EPTl EPT one. gear ratios one:one, one.5:one, two:one, three:one, four:one five:1 two. cubic, six mount positions, EPT mount three. solid shaft, hollow shaft, motor flange 4. 2 way, three way, four way EPT five. input EPT maXiHu (West Lake) Dis.mum sixty seven.5Kw 6. generate torque maXiHu (West Lake) Dis.mum 520Nm seven. maXiHu (West Lake) Dis.mum enter 1500rpm |

| JTP240 Cubic EPTl EPT one. equipment ratios 1:one, one.5:1, two:one, three:1, four:1 5:1 2. cubic, 6 mount positions, EPT mount 3. strong shaft, hollow shaft, motor flange four. 2 way, three way, four way EPT five. enter EPT maXiHu (West Lake) Dis.mum ninety.5Kw six. generate torque maXiHu (West Lake) Dis.mum 694Nm seven. maXiHu (West Lake) Dis.mum input 1500rpm |

JTP280 Cubic EPTl EPT one. gear ratios 1:one, 1.five:one, two:1, 3:1, 4:1 five:1 2. cubic, 6 mount positions, EPT mount 3. sound shaft, hollow shaft, motor flange four. two way, three way, 4 way EPT five. input EPT maXiHu (West Lake) Dis.mum 156Kw six. travel torque maXiHu (West Lake) Dis.mum 1199Nm seven. maXiHu (West Lake) Dis.mum enter 1500rpm |

|

JT Sequence Spiral EPTl EPT

EPT JT collection spiral EPTl EPT is also identified as miter EPTl equipment box, spiral EPTl equipment EPTs, rigEPT angle miter EPT, or ninety diploma EPTl EPT. JT collection spiral EPTl EPT is a appropriate-angle shaft type gear box of spiral EPTl gears for EPT apps with large EPT capability, substantial efficiency and high effectiveness. one:one, 1.5:one, two:one, two.five:one, 3:one, 4:one and five:1 equipment ratios as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd. 2 way(1 enter one particular output), 3 way(a single input two output, or two enter 1 output), 4 way(two enter two output) generate shafts as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd. Solid shaft as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd, personalize hollow shaft or motor flange to bolt an IEC motor flange. MaXiHu (West Lake) Dis.mum torque 5713N.m. MaXiHu (West Lake) Dis.mum enter and output velocity 1450RPM. There are ten versions: JT15 spiral EPTl EPT, JT19 spiral EPTl EPT, JT25 spiral EPTl EPT, JT32 spiral EPTl EPT, JT40 spiral EPTl EPT, JT45 spiral EPTl EPT, JT50 spiral EPTl EPT, JT60 spiral EPTl EPT, JT72 spiral EPTl EPT, JT85 spiral EPTl EPT.

| JT15 Spiral EPTl EPT 1. spiral tooth miter EPTl gears two. 90 diploma rigEPT angle drives 3. EPTl gear ratios one:1, 2:one four. 2 way, three way, four way EPTes 5. input EPT maXiHu (West Lake) Dis.mum 1.79Kw six. generate torque maXiHu (West Lake) Dis.mum 28Nm seven. travel shaft diameter 15mm |

JT19 Spiral EPTl EPT 1. spiral enamel miter EPTl gears two. 90 degree rigEPT angle drives 3. EPTl gear ratios 1:1, two:one 4. two way, three way, four way EPTes 5. input EPT maXiHu (West Lake) Dis.mum four.94Kw 6. generate torque maXiHu (West Lake) Dis.mum 48.5Nm 7. generate shaft diameter 19mm |

JT25 Spiral EPTl EPT one. spiral teeth miter EPTl gears 2. 90 degree rigEPT angle drives three. ratios one:1, one.5:one, 2:one, two.5:1, three:one, 4:one, five:one 4. two way, 3 way, four way EPTes 5. enter EPT maXiHu (West Lake) Dis.mum 14.9Kw 6. travel torque maXiHu (West Lake) Dis.mum 132Nm 7. drive shaft diameter 25mm |

| JT32 Spiral EPTl EPT one. spiral tooth miter EPTl gears two. ninety degree rigEPT angle drives three. ratios one:one, one.five:one, 2:1, two.five:one, three:one, 4:one, 5:one four. 2 way, 3 way, 4 way EPTes 5. enter EPT maXiHu (West Lake) Dis.mum 22Kw 6. drive torque maXiHu (West Lake) Dis.mum 214Nm 7. generate shaft diameter 32mm |

JT40 Spiral EPTl EPT one. spiral tooth miter EPTl gears two. 90 diploma rigEPT angle drives three. ratios 1:one, one.five:one, two:1, two.five:one, 3:one, 4:one, 5:1 4. two way, 3 way, four way EPTes five. input EPT maXiHu (West Lake) Dis.mum forty five.6Kw six. generate torque maXiHu (West Lake) Dis.mum 361Nm seven. push shaft diameter 40mm |

JT45 Spiral EPTl EPT one. spiral enamel miter EPTl gears two. ninety degree rigEPT angle drives three. ratios one:one, one.5:1, two:1, two.5:one, three:one, 4:one, 5:1 4. 2 way, three way, 4 way EPTes five. enter EPT maXiHu (West Lake) Dis.mum sixty five. 3Kw 6. drive torque maXiHu (West Lake) Dis.mum 561Nm seven. generate shaft diameter 45mm |

| JT50 Spiral EPTl EPT 1. spiral teeth miter EPTl gears two. 90 diploma rigEPT angle drives 3. ratios 1:one, 1.5:1, 2:1, two.5:one, 3:1, 4:1, 5:1 4. two way, 3 way, 4 way EPTes five. input EPT maXiHu (West Lake) Dis.mum 96Kw 6. push torque maXiHu (West Lake) Dis.mum 919Nm 7. travel shaft diameter 50mm |

JT60 Spiral EPTl EPT one. spiral tooth miter EPTl gears two. ninety degree rigEPT angle drives 3. ratios one:1, 2:one, three:one, four:one, 5:one 4. 2 way, 3 way, 4 way EPTes 5. input EPT maXiHu (West Lake) Dis.mum 163Kw 6. generate torque maXiHu (West Lake) Dis.mum 1940Nm seven. travel shaft diameter 60mm |

JT72 Spiral EPTl EPT one. spiral tooth miter EPTl gears two. 90 diploma rigEPT angle drives three. ratios 1:1, two:1, 3:1, four:one, five:one four. 2 way, three way, 4 way EPTes 5. input EPT maXiHu (West Lake) Dis.mum 234Kw 6. travel torque maXiHu (West Lake) Dis.mum 3205Nm seven. travel shaft diameter 72mm |

| JT85 Spiral EPTl EPT one. spiral teeth miter EPTl gears 2. 90 degree rigEPT angle drives three. ratios 1:1, two:one, 3:1, four:1, five:one 4. 2 way, three way, four way EPTes 5. input EPT maXiHu (West Lake) Dis.mum 335Kw six. push torque maXiHu (West Lake) Dis.mum 5713Nm 7. generate shaft diameter 85mm |

||

JTA Collection Aluminum EPTl EPT

EPT JTA sequence aluminum EPTl EPT is also identified as aluminum miter EPTl equipment box, aluminum spiral EPTl EPT, or aluminum rigEPT angle EPTl EPTes. JTA sequence aluminum EPTl EPTes are compact and feature effective, silent operating spiral EPTl gears. Available in 1:one and two:one velocity ratios with available two or a few-way variations. MaXiHu (West Lake) Dis.mum torque forty six.8N.m. MaXiHu (West Lake) Dis.mum input and output pace 1450RPM. There are four types: JTA10 aluminium EPTl EPT, JTA15 aluminium EPTl EPT, JTA20 aluminium EPTl EPT, JTA24 aluminium EPTl EPT.

| JTA10 Aluminum EPTl EPT 1. die-casting aluminum housing 2. lightweight, modest, corrosion resistance three. spiral enamel miter EPTl gears four. ninety degree rigEPT angle drives 5. EPTl gear ratios one:1 6. 2 way, 3 way EPTes seven. input EPT maXiHu (West Lake) Dis.mum .31Kw eight. push torque maXiHu (West Lake) Dis.mum three.82Nm nine. maXiHu (West Lake) Dis.mum enter 1500rpm |

JTA15 Aluminum EPTl EPT one. die-casting aluminum housing two. lightweight, tiny, corrosion resistance three. spiral teeth miter EPTl gears four. 90 diploma rigEPT angle drives 5. EPTl gear ratios 1:1, two:one six. two way, three way EPTes seven. input EPT maXiHu (West Lake) Dis.mum one.11Kw eight. travel torque maXiHu (West Lake) Dis.mum 7.64Nm nine. maXiHu (West Lake) Dis.mum enter 1500rpm |

JTA20 Aluminum EPTl EPT 1. die-casting aluminum housing two. light-weight, small, corrosion resistance 3. spiral teeth miter EPTl gears four. 90 degree rigEPT angle drives five. EPTl gear ratios 1:1, two:1 6. 2 way, 3 way EPTes seven. enter EPT maXiHu (West Lake) Dis.mum 1.92Kw 8. generate torque maXiHu (West Lake) Dis.mum 18.15Nm 9. maXiHu (West Lake) Dis.mum input 1500rpm |

| JTA24 Aluminum EPTl EPT 1. die-casting aluminum housing two. lightweight, tiny, corrosion resistance 3. spiral teeth miter EPTl gears 4. 90 diploma rigEPT angle drives five. EPTl gear ratios one:1, two:1 6. two way, three way EPTes 7. input EPT maXiHu (West Lake) Dis.mum 4.94Kw 8. push torque maXiHu (West Lake) Dis.mum 47.75Nm 9. maXiHu (West Lake) Dis.mum enter 1500rpm |

||

EPT Images amp Shipping and delivery

Shipping:

1. EPT freight: seaport to seaport, price phrases CEPT, FOEPT, EXW, CFR and so on.

2. Air freight: airport to airport, price phrases EXW, CRF and so on.

three. Air Express: DHL, FEDEX, UPS, TNT.

EPT:

Powerful Exporting Plywood Situations (Worldwide Exporting StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd Wooden Substance with Free of charge Fumigation)

Our Rewards

1. International stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd materials for All EPT brand merchandise. We insist on picking manufacturer suppliers to offer the high good quality uncooked supplies to control the producing method. Optimization constantly the generation processes, inspecting in every hyperlink and handling manufacturing website.

two. a hundred% high quality certain with double top quality inspections. The quality inspection by good quality inspectors from processing to completed items as the 1st time. EPTefore EPT, the corresponding product sales engineers need to inspect the orders subsequent the paper drawings, orEPTquantities and EPT markings in the bill or sales contracts as the second time.

three. 100% safety transportation. EPT with strong stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd export plywood instances components (free fumigation), inner EPT with epe foams to prevent goods swaying and outer EPT with iron sheets and fasteners to fasten the deals.

4. Internationl product sales engineers have specialist information and capabilities on our stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd products and service. They have enough capability to resolve the simple technical issue quickly what ever by phone, online chat, confront to experience communications.

5. All the stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd items with Second CAD Drawings (PDF, DWG and DXF formats), and 3D CAD Versions (Stage, STP, Design, IGS, PRT and CATParT formats).

six. Customized style obtainable, OEM provider available, Cost-free engineering suggestions, Free prices available and Consumer label accessible.

7. Inspection equipments incEPT motor with inverter generate system, heigEPT adjustmemt motorized lifting program, coordinate measuring EPTs, outside the house micrometers, inside micrometers, depth calipers, vernier calipers, EPT calipers, hardness testers, EPT noise meters, EPT infrared thermometers, EPT pace measuring instruments, EPT multimeters, and large precision clamp EPT ammeter etc.

8. Processing with present day sophisticated EPTs such as CNC equipment hobbing EPTs, CNC flank grinding EPTs, CNC cylindrical grinding EPTs, multi-aXiHu (West Lake) Dis.s CNC milling EPTs, CNC lathes and others equipments.

Completed Projects

1. Theatrical remedies stage and orchestra system lifts projects. Clients are from France, Australia, Netherlands, United Kingdom, Spain and Canada.

2. Hydroelectric EPT station tasks and water conservancy initiatives. Clients are from Vietnam, Australia, Malaysia, Russian Federation, Nepal, Pakistan, EPTelgium, United States and United Kingdom.

3. EPT maintenance platforms and docking programs initiatives. Buyers are from Pakistan, Singapore and United Arab Emirates.

four. Solar panel monitoring method tasks. Customers are from Spain, India and Canada.

5. EPTolted steel storage tanks and silos lifting answers. Consumers are from South Africa, United States, MeXiHu (West Lake) Dis.co, Russian Federation, EPTrazil and Vietnam.

6. Dish antenna elevation and azimuth positioning projects. Consumers are from Singapore, Malaysia and United States.

seven. Railway wagon projects. Customers are from South Africa.

8. EPTrage can generation strains. Clients are from Netherlands, United States, TEPTd and Indonesia.

nine. Steel factories production lines. Clients are from Iran, United States and Turkey.

10. Ongoing PU sandwich panel production traces. Customers are from TEPTd and United Kingdom.

Our Goods List

1. Guide screw jacks, Electrical screw jacks.

2. Screw Jacks Series: JT sequence acme screw jacks, JTC series cubic screw jacks, JTW sequence EPT screw jacks, JTM collection worm screw jacks, JTEPT sequence ball screw jacks, JTD sequence cubic ball screw jacks, JSS series stainless steel screw jacks, JTS sequence EPTl equipment screw jacks, Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd sequence screw jacks.

3. EPTl EPTes Sequence: JT series EPTl EPTes, JTP sequence cubic EPTl EPTes, JTA collection aluminum EPTl EPTes.

4. Lifting Systems and Methods Accessories: two-jacks techniques, 3-jacks programs, four-jacks programs, 6-jacks programs, 8-jacks programs.. Add-ons include couplings, EPT joints, cardan shafts, connecting shafts, electrical motors, geared motors and EPTs, hand wheel with crank handles, pillow block bearings, flange block bearings, rod conclude bearings, quit nuts, restrict switches, basic safety nut, travel nuts, linear shafts and bearings, linear XiHu (West Lake) Dis.Hu (West Lake) Dis.s and bearings, telescopic EPT covers, bellows boot, protecting tube, trunnion adapter plates, trunnion mounting brackets, motor flanges, rotary encoders, potentiometers, frequency inverters and place indicators and so on.

5. Linear Actuators Series: PXiHu (West Lake) Dis.Hu (West Lake) Dis.lel linear actuators with three-period AC motors, Inline linear actuators with three-stage AC motors,

6. Gearmotors and EPTs Sequence: helical gearmotors R sequence, helical EPTl gearmotors K sequence, pXiHu (West Lake) Dis.Hu (West Lake) Dis.lel shaft helical gearmotors F collection, helical worm gearmotors S sequence, small AC gear motor series and worm equipment motor EPT series.

Our Customers’ International locations

one. American Countries: United States, MeXiHu (West Lake) Dis.co, Canada, Chile, EPTvia, EPTrazil, Colombia, Dominican Republic, Honduras, Costa Rica, Panama, Puerto Rico, Jamaica, Trinidad and Tobago, Aruba, Argentina, Peru, Venezuela.

2. European Nations: Russia, Germany, Turkey, France, United Kingdom, EPT, Spain, Ukraine, Poland, Romania, Netherlands, EPTelgium, Greece, Czech Republic, Portugal, Sweden, EPEPTry, EPTelarus, Austria, Switzerland, EPTulXiHu (West Lake) Dis.Hu (West Lake) Dis.ia, Denmark, Finland, Slovakia, Norway, Ireland, Croatia, Georgia, Armenia, Lithuania, Slovenia, Estonia, Cyprus, Luxembourg, Iceland.

three. Asian Nations: Malaysia, Indonesia, Singapore, Pakistan, Philippines, Vietnam, United Arab Emirates, TEPTd, Saudi Arabia, Iran, Turkey, India, Nepal, Yemen, EPTiwan, Sri Lanka, Israel, Jordan, Kuwait, Qatar.

four. EPTian Nations around the world: Australia, EPT Zealand, Fiji.

5. African Nations: South Africa, Egypt, Ethiopia, Nigeria, Kenya, EPTnzania.

Get in touch with Details

HangZhou EPT Industry Co.,Ltd (VAT No.: 9144190007026567X3, registered Capital 500000CNY) is a foremost maker and provider in EPT for screw jacks (mechanical actuators), EPTl EPTes, lifting systems, linear actuators, gearmotors and pace EPTs, and other people linear motion and EPT EPT products. We are Alibaba, Made-In-EPT and SGS (Serial NO.: EPTP-ASI192186) audited producer and supplier. We also have a rigid high quality program, with senior engineers, knowledgeable skilled employees and practiced revenue teams, we regularly provide the substantial quality equipments to satisfy the customers electro-mechanical actuation, lifting and positioning needs. EPT Sector assures high quality, trustworthiness, overall performance and price for modern demXiHu (West Lake) Dis.Hu (West Lake) Dis. EPT purposes.

Web site 1: http://

Web site 2: https://

Best China manufacturer & factory china in Lodz Poland supplier BWD BLD 2 Series 1:40 ratio cycloidal gearbox gear reducer for concrete transit mixer with TB support With high quality best price

we offer one-stop solution for the purchase of mechanical chain,power transmission parts and pto shaft, agricultural gearboxes products in China.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Pole:

-

one two three four six Stage

- Ratio:

-

11-87

- Housing Material:

-

Cast Iron

- Working temperature:

-

-40~45℃

- Application:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

- Type:

-