Product Description

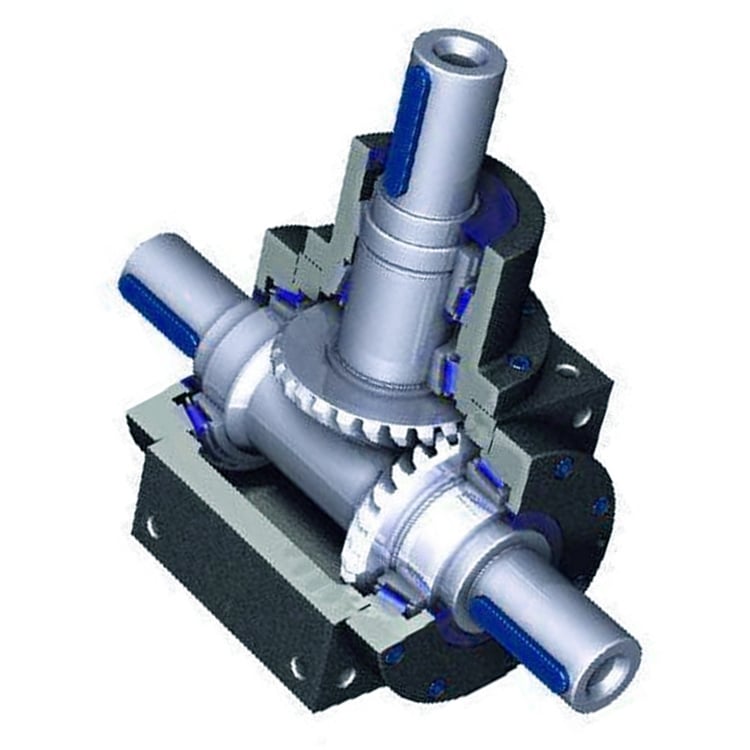

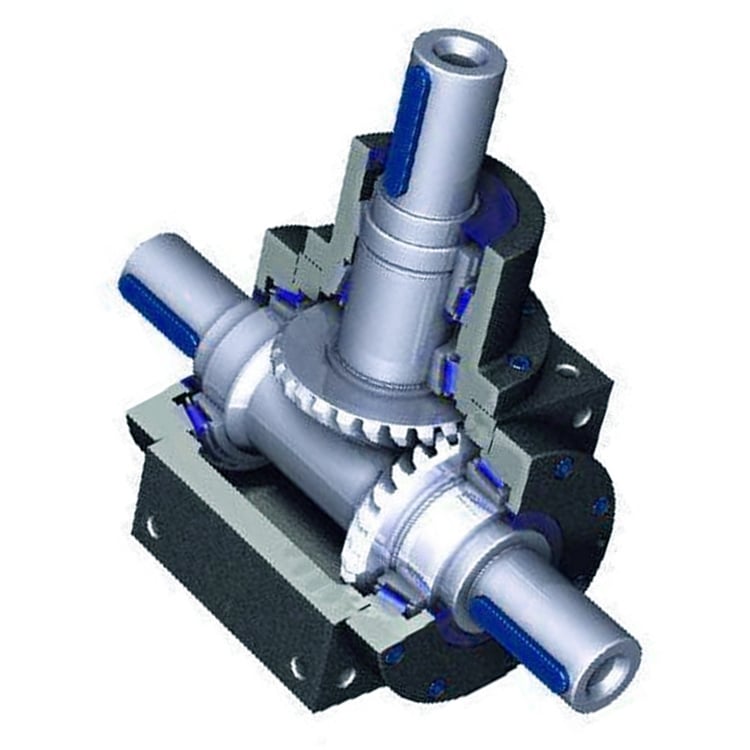

Detailed Photos

Product Parameters

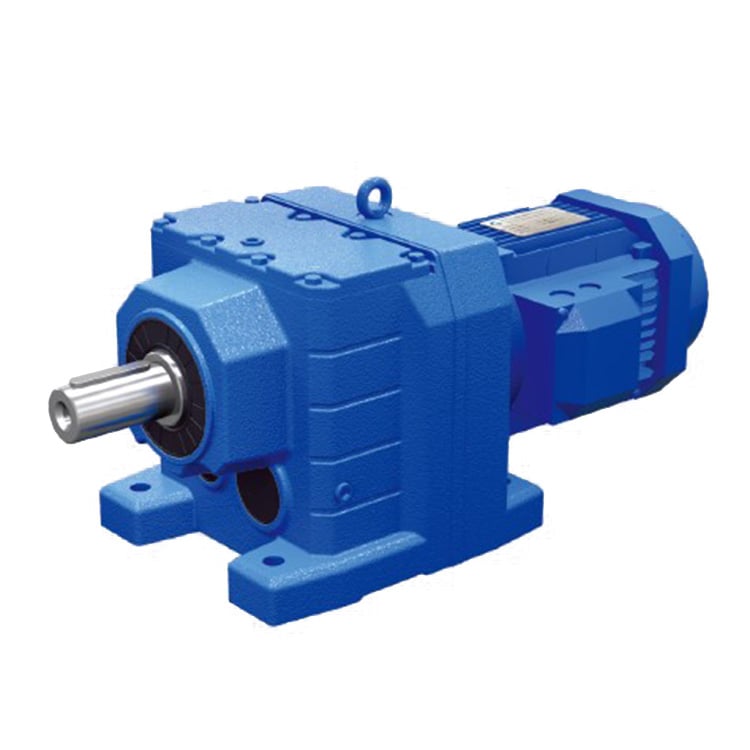

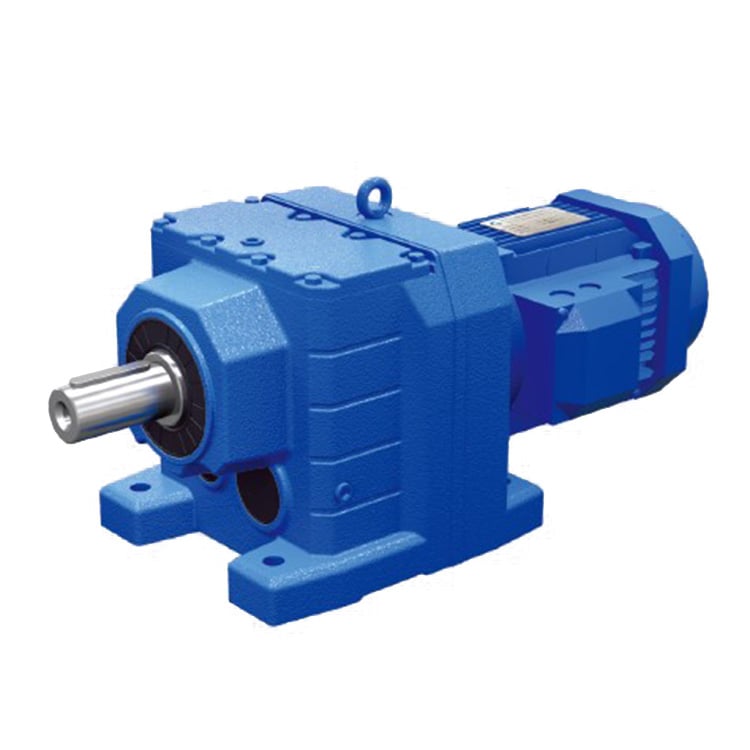

Products Description

R Series Helical Speed Reducers

R series helical gear reducer has high technological content; it adopts hardened gear surface design, which is reliable and durable and has high overload capacity.

It has the following characteristics

1,R series helical gear reducer is manufactured in accordance with international technical requirements, meeting the technical

requirements of most countries in the world.

2,The design of R series helical gear reducer plays a space-saving, high overload capacity.

3, R series helical gear reducer has low energy consumption, superior performance and high efficiency of more than 95%;

4,R series helical gear reducer has low vibration, low noise, and high energy saving;

5,R series helical gear reducer is made of high quality forged steel material, steel cast iron case, and the surface of gear is heat-treated by high frequency; reliable and durableTranslated with DeepL

R Series reducers are designed and manufactured on the basis of modular combination system.

There are a lot of motor combinations, installation forms and structural schemes. The transmission

ratio is classified and fine to meet different operating conditions, and the performance is superior.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface

is carburized, quenched and hardened, and the gear is finely ground. It has stable transmission, low

noise, and large bearing capacity. Low temperature rise, long service life. It is widely used in metallurgy,1. Features: small offset output, compact structure, maximum use of box space, use of integral casting box, good stiffness, can improve the strength of the shaft and bearing life.

2. Installation type and output mode: bottom seated type and large and small flange type installation, CHINAMFG shaft output.

3. Input mode: direct motor, shaft input and connecting flange input.

4. Reduction ratio: secondary 5~24.8, tertiary 27.2~264, R/R combination up to 18125.

5. Average efficiency: Class II 96%, Class III 94%, R/R combination 85%.

6. The R series specially designed for mixing can bear large axial and radial forces.

Technical parameters:

Coaxial coaxial output

R reducer

Power: 0.12KW~160KW

Torque: 1.4N · m ~ 23200N · m

Output speed: 0.06 ~ 1090r/min

Model example:

R17-Y4-4P-32.40-M1-0°

R: Series code

F: Shaft extension flange installation

17: Machine model

Y: Three phase AC asynchronous motor

4: Motor power

4P: motor stage

32.40: Transmission ratio

M1: Installation type

0 °: junction box position (0 ° – 270 °)

R series helical gear hardened gear reducer

Basic model of R series reducer:

R17R27R37R47R57R67R77R87R97R107R137R147R167

RF17RF27RF37RF47RF57RF67RF77RF87RF97RF107RF137RF147RF167

RX37RX57RX67RX77RX87RX97RX107RX127RX157

RXF37RXF57RXF67RXF77RXF87RXF97RXF107RXF127RXF157

R series helical gear reducer with hard tooth surface features small size, light weight, high bearing capacity, high efficiency, long service life, convenient installation, wide motor power range, fine transmission ratio classification, etc. It can be widely used in equipment that needs to be decelerated in various industries.

sewage treatment, chemical industry, pharmacy and other industries.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1780/Piece

1 Piece(Min.Order) | |

|---|

What factors should be considered when selecting an AC motor for a particular application?

When selecting an AC motor for a particular application, several factors need to be considered to ensure the motor meets the requirements and performs optimally. Here are the key factors to consider:

- Power Requirements: Determine the power requirements of the application, including the required torque and speed. The motor should have adequate power output to meet the demands of the specific task. Consider factors such as starting torque, running torque, and speed range to ensure the motor can handle the load effectively.

- Motor Type: There are different types of AC motors, including induction motors, synchronous motors, and brushless DC motors. Each type has its own characteristics and advantages. Consider the application’s requirements and factors such as speed control, efficiency, and starting torque to determine the most suitable motor type.

- Environmental Conditions: Assess the environmental conditions in which the motor will operate. Factors such as temperature, humidity, dust, and vibration levels can impact motor performance and longevity. Choose a motor that is designed to withstand the specific environmental conditions of the application.

- Size and Space Constraints: Consider the available space for motor installation. Ensure that the physical dimensions of the motor, including its length, diameter, and mounting arrangement, are compatible with the available space. Additionally, consider the weight of the motor if it needs to be mounted or transported.

- Efficiency: Energy efficiency is an important consideration, as it can impact operational costs and environmental sustainability. Look for motors with high efficiency ratings, which indicate that they convert electrical energy into mechanical energy with minimal energy loss. Energy-efficient motors can lead to cost savings and reduced environmental impact over the motor’s lifespan.

- Control and Speed Requirements: Determine if the application requires precise speed control or if a fixed speed motor is sufficient. If variable speed control is needed, consider motors that can be easily controlled using variable frequency drives (VFDs) or other speed control mechanisms. For applications that require high-speed operation, select a motor that can achieve the desired speed range.

- Maintenance and Serviceability: Assess the maintenance requirements and serviceability of the motor. Consider factors such as the accessibility of motor components, ease of maintenance, availability of spare parts, and the manufacturer’s reputation for reliability and customer support. A motor that is easy to maintain and service can help minimize downtime and repair costs.

- Budget: Consider the budget constraints for the motor selection. Balance the desired features and performance with the available budget. In some cases, investing in a higher quality, more efficient motor upfront can lead to long-term cost savings due to reduced energy consumption and maintenance requirements.

By carefully considering these factors, it is possible to select an AC motor that aligns with the specific requirements of the application, ensuring optimal performance, efficiency, and reliability.

Are there energy-saving technologies or features available in modern AC motors?

Yes, modern AC motors often incorporate various energy-saving technologies and features designed to improve their efficiency and reduce power consumption. These advancements aim to minimize energy losses and optimize motor performance. Here are some energy-saving technologies and features commonly found in modern AC motors:

- High-Efficiency Designs: Modern AC motors are often designed with higher efficiency standards compared to older models. These motors are built using advanced materials and optimized designs to reduce energy losses, such as resistive losses in motor windings and mechanical losses due to friction and drag. High-efficiency motors can achieve energy savings by converting a higher percentage of electrical input power into useful mechanical work.

- Premium Efficiency Standards: International standards and regulations, such as the NEMA Premium® and IE (International Efficiency) classifications, define minimum energy efficiency requirements for AC motors. Premium efficiency motors meet or exceed these standards, offering improved efficiency compared to standard motors. These motors often incorporate design enhancements, such as improved core materials, reduced winding resistance, and optimized ventilation systems, to achieve higher efficiency levels.

- Variable Frequency Drives (VFDs): VFDs, also known as adjustable speed drives or inverters, are control devices that allow AC motors to operate at variable speeds by adjusting the frequency and voltage of the electrical power supplied to the motor. By matching the motor speed to the load requirements, VFDs can significantly reduce energy consumption. VFDs are particularly effective in applications where the motor operates at a partial load for extended periods, such as HVAC systems, pumps, and fans.

- Efficient Motor Control Algorithms: Modern motor control algorithms, implemented in motor drives or control systems, optimize motor operation for improved energy efficiency. These algorithms dynamically adjust motor parameters, such as voltage, frequency, and current, based on load conditions, thereby minimizing energy wastage. Advanced control techniques, such as sensorless vector control or field-oriented control, enhance motor performance and efficiency by precisely regulating the motor’s magnetic field.

- Improved Cooling and Ventilation: Effective cooling and ventilation are crucial for maintaining motor efficiency. Modern AC motors often feature enhanced cooling systems, including improved fan designs, better airflow management, and optimized ventilation paths. Efficient cooling helps prevent motor overheating and reduces losses due to heat dissipation. Some motors also incorporate thermal monitoring and protection mechanisms to avoid excessive temperatures and ensure optimal operating conditions.

- Bearings and Friction Reduction: Friction losses in bearings and mechanical components can consume significant amounts of energy in AC motors. Modern motors employ advanced bearing technologies, such as sealed or lubrication-free bearings, to reduce friction and minimize energy losses. Additionally, optimized rotor and stator designs, along with improved manufacturing techniques, help reduce mechanical losses and enhance motor efficiency.

- Power Factor Correction: Power factor is a measure of how effectively electrical power is being utilized. AC motors with poor power factor can contribute to increased reactive power consumption and lower overall power system efficiency. Power factor correction techniques, such as capacitor banks or power factor correction controllers, are often employed to improve power factor and minimize reactive power losses, resulting in more efficient motor operation.

By incorporating these energy-saving technologies and features, modern AC motors can achieve significant improvements in energy efficiency, leading to reduced power consumption and lower operating costs. When considering the use of AC motors, it is advisable to select models that meet or exceed recognized efficiency standards and consult manufacturers or experts to ensure the motor’s compatibility with specific applications and energy-saving requirements.

Can you explain the basic working principle of an AC motor?

An AC motor operates based on the principles of electromagnetic induction. It converts electrical energy into mechanical energy through the interaction of magnetic fields. The basic working principle of an AC motor involves the following steps:

- The AC motor consists of two main components: the stator and the rotor. The stator is the stationary part of the motor and contains the stator windings. The rotor is the rotating part of the motor and is connected to a shaft.

- When an alternating current (AC) is supplied to the stator windings, it creates a changing magnetic field.

- The changing magnetic field induces a voltage in the rotor windings, which are either short-circuited conductive bars or coils.

- The induced voltage in the rotor windings creates a magnetic field in the rotor.

- The magnetic field of the rotor interacts with the rotating magnetic field of the stator, resulting in a torque force.

- The torque force causes the rotor to rotate, transferring mechanical energy to the connected shaft.

- The rotation of the rotor continues as long as the AC power supply is provided to the stator windings.

This basic working principle is applicable to various types of AC motors, including induction motors and synchronous motors. However, the specific construction and design of the motor may vary depending on the type and intended application.

editor by CX 2024-04-12

China Professional Best Price High Torque PA140 Helical Gear Planetary Gearbox Speed Reducer with Hot selling

Product Description

Best Price High Torque PA140 Helical Gear Planetary Gearbox Speed Reducer

The high-precision planetary gearbox adopts spur gear design, and is used in various control transmission fields with servo motors, such as precision machine tools, laser cutting equipment, battery processing equipment, etc. It has the advantages of large torsional rigidity and large output torque.

*PA series helical gear shaft output planetary reducer

*PX series helical gear shaft output planetary reducer

*PG series helical gear flange output planetary reducer

*PW series helical gear shaft output planetary reducer

*PXR series helical gear right angle planetary reducer

*PAR series helical gear right angle planetary reducer

*PRF series spur gear shaft output planetary reducer

*PRL series spur gear shaft output planetary reducer

*PRN series spur gear flange output planetary reducer

*PFN series spur gear square output planetary reducer

*PVFN series spur gear 90 degree right angle planetary reducer

*PVLN series spur gear 90 degree right angle planetary reducer

Product Parameters

| Specifications | PA60 | PA90 | PA120 | PA140 | PA180 | PA220 | |||

| Technal Parameters | |||||||||

| Max. Torque | Nm | 1.5times rated torque | |||||||

| Emergency Stop Torque | Nm | 2.5times rated torque | |||||||

| Max. Radial Load | N | 1530 | 3250 | 6700 | 9400 | 14500 | 16500 | ||

| Max. Axial Load | N | 630 | 1300 | 3000 | 4700 | 7250 | 8250 | ||

| Torsional Rigidity | Nm/arcmin | 6 | 12 | 23 | 47 | 130 | 205 | ||

| Max.Input Speed | rpm | 8000 | 6000 | 6000 | 6000 | 6000 | 3000 | ||

| Rated Input Speed | rpm | 4000 | 3000 | 3000 | 3000 | 3000 | 1500 | ||

| Noise | dB | ≤58 | ≤60 | ≤65 | ≤68 | ≤68 | ≤72 | ||

| Average Life Time | h | 20000 | |||||||

| Efficiency Of Full Load | % | L1≥95% L2≥90% | |||||||

| Return Backlash | P1 | L1 | arcmin | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | arcmin | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| P2 | L1 | arcmin | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |

| L2 | arcmin | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| Moment Of Inertia Table | L1 | 3 | Kg*cm2 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.7 |

| 4 | Kg*cm2 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.61 | ||

| 5 | Kg*cm2 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.51 | ||

| 7 | Kg*cm2 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.92 | ||

| 8 | Kg*cm2 | 0.13 | 0.45 | 2.6 | 7.14 | / | / | ||

| 10 | Kg*cm2 | 0.13 | 0.4 | 2.57 | 7.03 | 22.51 | 50.18 | ||

| L2 | 12 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.63 | 7.3 | 23.59 | |

| 15 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.63 | 7.3 | 23.59 | ||

| 20 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.63 | 6.92 | 23.33 | ||

| 25 | Kg*cm2 | 0.13 | 0.45 | 0.4 | 2.63 | 6.92 | 22.68 | ||

| 28 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.43 | 6.92 | 23.33 | ||

| 30 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.43 | 7.3 | 25.59 | ||

| 35 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.43 | 6.92 | 22.68 | ||

| 40 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.43 | 6.92 | 23.33 | ||

| 50 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.39 | 6.92 | 22.68 | ||

| 70 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.39 | 6.72 | 22.68 | ||

| 100 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.39 | 6.72 | 22.68 | ||

| Technical Parameter | Level | Ratio | PA60 | PA90 | PA120 | PA140 | PA180 | PA220 | |

| Rated Torque | L1 | 3 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 |

| 4 | Nm | 45 | 130 | 230 | 480 | 880 | 1800 | ||

| 5 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 7 | Nm | 45 | 100 | 220 | 480 | 1100 | 1600 | ||

| 8 | Nm | 40 | 90 | 200 | 440 | / | / | ||

| 10 | Nm | 30 | 75 | 175 | 360 | 770 | 1200 | ||

| L2 | 12 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 | |

| 15 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 | ||

| 20 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 25 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 28 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 30 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 | ||

| 35 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 40 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 50 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 70 | Nm | 45 | 100 | 220 | 480 | 1100 | 1600 | ||

| 100 | Nm | 30 | 75 | 175 | 360 | 770 | 1200 | ||

| Degree Of Protection | IP65 | ||||||||

| Operation Temprature | ºC | – 10ºC to -90ºC | |||||||

| Weight | L1 | kg | 1.25 | 3.75 | 8.5 | 16 | 28.5 | 49.3 | |

| L2 | kg | 1.75 | 5.1 | 12 | 21.5 | 40 | 62.5 | ||

Company Profile

Packaging & Shipping

1. Lead time: 7-10 working days as usual, 20 working days in busy season, it will be based on the detailed order quantity;

2. Delivery: DHL/ UPS/ FEDEX/ EMS/ TNT

FAQ

1. who are we?

Hefa Group is based in ZheJiang , China, start from 1998,has a 3 subsidiaries in total.The Main Products is planetary gearbox,timing belt pulley, helical gear,spur gear,gear rack,gear ring,chain wheel,hollow rotating platform,module,etc

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.how to choose the suitable planetary gearbox?

First of all,we need you to be CZPT to provide relevant parameters.If you have a motor drawing,it will let us recommend a suitable gearbox for you faster.If not,we hope you can provide the following motor parameters:output speed,output torque,voltage,current,ip,noise,operating conditions,motor size and power,etc

4. why should you buy from us not from other suppliers?

We are a 22 years experiences manufacturer on making the gears, specializing in manufacturing all kinds of spur/bevel/helical gear, grinding gear, gear shaft, timing pulley, rack, planetary gear reducer, timing belt and such transmission gear parts

5. what services can we provide?

Accepted Delivery Terms: Fedex,DHL,UPS;

Accepted Payment Currency:USD,EUR,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union;

Language Spoken:English,Chinese,Japanese

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Automation Equipment |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Bevel Gear |

| Step: | Double-Step |

| Samples: |

US$ 350/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

The Benefits of Using a Gear Motor

A gear motor works on the principle of conservation of angular momentum. As the smaller gear covers more RPM and the larger gear produces more torque, the ratio between the two is greater than one. Similarly, a multiple gear motor follows the principle of energy conservation, with the direction of rotation always opposite to the one that is adjacent to it. It’s easy to understand the concept behind gear motors and the various types available. Read on to learn about the different types of gears and their applications.

Electric motor

The choice of an electric motor for gear motor is largely dependent on the application. There are various motor and gearhead combinations available, and some are more efficient than others. However, it is critical to understand the application requirements and select a motor that meets these needs. In this article, we’ll examine some of the benefits of using a gear motor. The pros and cons of each type are briefly discussed. You can buy new gear motors at competitive prices, but they aren’t the most reliable or durable option for your application.

To determine which motor is best for your application, you’ll need to consider the load and speed requirements. A gear motor’s efficiency (e) can be calculated by taking the input and output values and calculating their relation. On the graph below, the input (T) and output (P) values are represented as dashed lines. The input (I) value is represented as the torque applied to the motor shaft. The output (P) is the amount of mechanical energy converted. A DC gear motor is 70% efficient at 3.75 lb-in / 2,100 rpm.

In addition to the worm gear motor, you can also choose a compact DC worm gear motor with a variable gear ratio from 7.5 to 80. It has a range of options and can be custom-made for your specific application. The 3-phase AC gear motor, on the other hand, works at a rated power of one hp and torque of 1.143.2 kg-m. The output voltage is typically 220V.

Another important factor is the output shaft orientation. There are two main orientations for gearmotors: in-line and offset. In-line output shafts are most ideal for applications with high torque and short reduction ratios. If you want to avoid backlash, choose a right angle output shaft. An offset shaft can cause the output shaft to become excessively hot. If the output shaft is angled at a certain angle, it may be too large or too small.

Gear reducer

A gear reducer is a special kind of speed reducing motor, usually used in large machinery, such as compressors. These reducers have no cooling fan and are not designed to handle heavy loads. Different purposes require different service factors. For instance, a machine that requires frequent fast accelerations and occasional load spikes needs a gear reducer with a high service factor. A gear reducer that’s designed for long production shifts should be larger than a machine that uses it for short periods of time.

A gear reducer can reduce the speed of a motor by a factor of two. The reduction ratio changes the rotation speed of the receiving member. This change in speed is often required to solve problems of inertia mismatch. The torque density of a gear reducer is measured in newton meters and will depend on the motor used. The first criterion is the configuration of the input and output shafts. A gear ratio of 2:1, for example, means that the output speed has been cut in half.

Bevel gear reducers are a good option if the input and output shafts are perpendicular. This type is very robust and is perfect for situations where the angle between two axes is small. However, bevel gear reducers are expensive and require constant maintenance. They are usually used in heavy-duty conveyors and farm equipment. The correct choice of gear reducer for gear motor is crucial for the efficiency and reliability of the mechanism. To get the best gear reducer for your application, talk to a qualified manufacturer today.

Choosing a gear reducer for a gear motor can be tricky. The wrong one can ruin an entire machine, so it’s important to know the specifics. You must know the torque and speed requirements and choose a motor with the appropriate ratio. A gear reducer should also be compatible with the motor it’s intended for. In some cases, a smaller motor with a gear reducer will work better than a larger one.

Motor shaft

Proper alignment of the motor shaft can greatly improve the performance and life span of rotating devices. The proper alignment of motors and driven instruments enhances the transfer of energy from the motor to the instrument. Incorrect alignment leads to additional noise and vibration. It may also lead to premature failure of couplings and bearings. Misalignment also results in increased shaft and coupling temperatures. Hence, proper alignment is critical to improve the efficiency of the driven instrument.

When choosing the correct type of gear train for your motor, you need to consider its energy efficiency and the torque it can handle. A helical geared motor is more efficient for high output torque applications. Depending on the required speed and torque, you can choose between an in-line and a parallel helical geared motor. Both types of gears have their advantages and disadvantages. Spur gears are widespread. They are toothed and run parallel to the motor shaft.

A planetary gear motor can also have a linear output shaft. A stepping motor should not operate at too high current to prevent demagnetization, which will lead to step loss or torque drop. Ensure that the motor and gearbox output shafts are protected from external impacts. If the motor and gearbox are not protected against bumps, they may cause thread defects. Make sure that the motor shafts and rotors are protected from external impacts.

When choosing a metal for your gear motor’s motor shaft, you should consider the cost of hot-rolled bar stock. Its outer layers are more difficult to machine. This type of material contains residual stresses and other problems that make it difficult to machine. For these applications, you should choose a high-strength steel with hard outer layers. This type of steel is cheaper, but it also has size considerations. It’s best to test each material first to determine which one suits your needs.

In addition to reducing the speed of your device, a geared motor also minimizes the torque generated by your machine. It can be used with both AC and DC power. A high-quality gear motor is vital for stirring mechanisms and conveyor belts. However, you should choose a geared motor that uses high-grade gears and provides maximum efficiency. There are many types of planetary gear motors and gears on the market, and it’s important to choose the right one.

First stage gears

The first stage gears of a gear motor are the most important components of the entire device. The motor’s power transmission is 90% efficient, but there are many factors that can affect its performance. The gear ratios used should be high enough to handle the load, but not too high that they are limiting the motor’s speed. A gear motor should also have a healthy safety factor, and the lubricant must be sufficient to overcome any of these factors.

The transmission torque of the gear changes with its speed. The transmission torque at the input side of the gear decreases, transferring a small torque to the output side. The number of teeth and the pitch circle diameters can be used to calculate the torque. The first stage gears of gear motors can be categorized as spur gears, helical gears, or worm gears. These three types of gears have different torque capacities.

The first stage helical gear is the most important part of a gear motor. Its function is to transfer rotation from one gear to the other. Its output is the gearhead. The second stage gears are connected by a carrier. They work in tandem with the first stage gear to provide the output of the gearhead. Moreover, the first stage carrier rotates in the same direction as the input pinion.

Another important component is the output torque of the gearmotor. When choosing a gearmotor, consider the starting torque, running torque, output speed, overhung and shock loads, duty cycles, and more. It is crucial to choose a gearmotor with the right ratio for the application. By choosing the proper gearmotor, you will get maximum performance with minimal operating costs and increase plant productivity. For more information on first stage gears, check out our blog.

The first stage of a gear motor is composed of a set of fixed and rotating sprockets. The first stage of these gears acts as a drive gear. Its rotational mass is a limiting factor for torque. The second stage consists of a rotating shaft. This shaft rotates in the direction of the torque axis. It is also the limiting force for the motor’s torque.

editor by CX 2023-11-15

China best Hot Sale High Toruqe Helical Bevel Gear Speed Reducer For Motor worm gear motor

Warranty: 1 years

Applicable Industries: Building Material Shops, Construction works , Energy & Mining, Farms, Food & Beverage Factory, Food & Beverage Shops, Machinery Repair Shops, Manufacturing Plant, Printing Shops, Retail

Customized support: OBM, ODM, OEM

Gearing Arrangement: Planetary

Output Torque: 78 N.M

Input Speed: 3

Q1: What’re your main products?A1: High Precision Planetary Gearbox; High Precision Quality Wpa Transmission Gear Reducer Horizontal Gear Box Hollow Rotating Platform; Precision Steering Box; Worm Speed Reducer; Worm Screw Jack; R/K/F/S GearboxQ2: What industries are your gearboxes being used in?A2: Gearboxes are widely used in the areas of robotics, textile, food processing, beverage, chemical industry, escalator, automatic storage equipment, metallurgy, environmental protection, logistics, etc.Q3: Can you offer OEM or ODM service?A3: Yes, we are a professional manufacturer so we can do customized orders.Q4: How to choose a model?A4: We have one-1 service team for model selection, and we can provide CAD drawings and 3D models in 5 minutes with technical information of required output torque, output speed and motor parameters etc. So just contact us.Q5: What information shall we give before placing a purchase order?A5: We understand your needs from the following information: a) Type of the gearbox, ratio, input and output type, input flange, High Temperature Resistance NMRV Series 9-4 Copper Worm High Efficiency Durable Worm Gear Speed Reducer mounting position, and motor information etc.b) Housing color.c) Purchase quantity.d) Other special requirements.Q6: How long is the delivery time?A6: Most planetary gearboxes are in stock. 7 working days for worm speed reducer and worm screw jack, 15 working days for R/K/F/S gearbox.

The Difference Between Planetary Gears and Spur Gears

A spur gear is a type of mechanical drive that turns an external shaft. The angular velocity is proportional to the rpm and can be easily calculated from the gear ratio. However, to properly calculate angular velocity, it is necessary to know the number of teeth. Fortunately, there are several different types of spur gears. Here’s an overview of their main features. This article also discusses planetary gears, which are smaller, more robust, and more power-dense.

Planetary gears are a type of spur gear

One of the most significant differences between planetary gears and spurgears is the way that the two share the load. Planetary gears are much more efficient than spurgears, enabling high torque transfer in a small space. This is because planetary gears have multiple teeth instead of just one. They are also suitable for intermittent and constant operation. This article will cover some of the main benefits of planetary gears and their differences from spurgears.

While spur gears are more simple than planetary gears, they do have some key differences. In addition to being more basic, they do not require any special cuts or angles. Moreover, the tooth shape of spur gears is much more complex than those of planetary gears. The design determines where the teeth make contact and how much power is available. However, a planetary gear system will be more efficient if the teeth are lubricated internally.

In a planetary gear, there are three shafts: a sun gear, a planet carrier, and an external ring gear. A planetary gear is designed to allow the motion of one shaft to be arrested, while the other two work simultaneously. In addition to two-shaft operation, planetary gears can also be used in three-shaft operations, which are called temporary three-shaft operations. Temporary three-shaft operations are possible through frictional coupling.

Among the many benefits of planetary gears is their adaptability. As the load is shared between several planet gears, it is easier to switch gear ratios, so you do not need to purchase a new gearbox for every new application. Another major benefit of planetary gears is that they are highly resistant to high shock loads and demanding conditions. This means that they are used in many industries.

They are more robust

An epicyclic gear train is a type of transmission that uses concentric axes for input and output. This type of transmission is often used in vehicles with automatic transmissions, such as a Lamborghini Gallardo. It is also used in hybrid cars. These types of transmissions are also more robust than conventional planetary gears. However, they require more assembly time than a conventional parallel shaft gear.

An epicyclic gearing system has three basic components: an input, an output, and a carrier. The number of teeth in each gear determines the ratio of input rotation to output rotation. In some cases, an epicyclic gear system can be made with two planets. A third planet, known as the carrier, meshes with the second planet and the sun gear to provide reversibility. A ring gear is made of several components, and a planetary gear may contain many gears.

An epicyclic gear train can be built so that the planet gear rolls inside the pitch circle of an outer fixed gear ring, or “annular gear.” In such a case, the curve of the planet’s pitch circle is called a hypocycloid. When epicycle gear trains are used in combination with a sun gear, the planetary gear train is made up of both types. The sun gear is usually fixed, while the ring gear is driven.

Planetary gearing, also known as epicyclic gear, is more durable than other types of transmissions. Because planets are evenly distributed around the sun, they have an even distribution of gears. Because they are more robust, they can handle higher torques, reductions, and overhung loads. They are also more energy-dense and robust. In addition, planetary gearing is often able to be converted to various ratios.

They are more power dense

The planet gear and ring gear of a compound planetary transmission are epicyclic stages. One part of the planet gear meshes with the sun gear, while the other part of the gear drives the ring gear. Coast tooth flanks are used only when the gear drive works in reversed load direction. Asymmetry factor optimization equalizes the contact stress safety factors of a planetary gear. The permissible contact stress, sHPd, and the maximum operating contact stress (sHPc) are equalized by asymmetry factor optimization.

In addition, epicyclic gears are generally smaller and require fewer space than helical ones. They are commonly used as differential gears in speed frames and in looms, where they act as a Roper positive let off. They differ in the amount of overdrive and undergearing ratio they possess. The overdrive ratio varies from fifteen percent to forty percent. In contrast, the undergearing ratio ranges from 0.87:1 to 69%.

The TV7-117S turboprop engine gearbox is the first known application of epicyclic gears with asymmetric teeth. This gearbox was developed by the CZPT Corporation for the Ilyushin Il-114 turboprop plane. The TV7-117S’s gearbox arrangement consists of a first planetary-differential stage with three planet gears and a second solar-type coaxial stage with five planet gears. This arrangement gives epicyclic gears the highest power density.

Planetary gearing is more robust and power-dense than other types of gearing. They can withstand higher torques, reductions, and overhung loads. Their unique self-aligning properties also make them highly versatile in rugged applications. It is also more compact and lightweight. In addition to this, epicyclic gears are easier to manufacture than planetary gears. And as a bonus, they are much less expensive.

They are smaller

Epicyclic gears are small mechanical devices that have a central “sun” gear and one or more outer intermediate gears. These gears are held in a carrier or ring gear and have multiple mesh considerations. The system can be sized and speeded by dividing the required ratio by the number of teeth per gear. This process is known as gearing and is used in many types of gearing systems.

Planetary gears are also known as epicyclic gearing. They have input and output shafts that are coaxially arranged. Each planet contains a gear wheel that meshes with the sun gear. These gears are small and easy to manufacture. Another advantage of epicyclic gears is their robust design. They are easily converted into different ratios. They are also highly efficient. In addition, planetary gear trains can be designed to operate in multiple directions.

Another advantage of epicyclic gearing is their reduced size. They are often used for small-scale applications. The lower cost is associated with the reduced manufacturing time. Epicyclic gears should not be made on N/C milling machines. The epicyclic carrier should be cast and tooled on a single-purpose machine, which has several cutters cutting through material. The epicyclic carrier is smaller than the epicyclic gear.

Epicyclic gearing systems consist of three basic components: an input, an output, and a stationary component. The number of teeth in each gear determines the ratio of input rotation to output rotation. Typically, these gear sets are made of three separate pieces: the input gear, the output gear, and the stationary component. Depending on the size of the input and output gear, the ratio between the two components is greater than half.

They have higher gear ratios

The differences between epicyclic gears and regular, non-epicyclic gears are significant for many different applications. In particular, epicyclic gears have higher gear ratios. The reason behind this is that epicyclic gears require multiple mesh considerations. The epicyclic gears are designed to calculate the number of load application cycles per unit time. The sun gear, for example, is +1300 RPM. The planet gear, on the other hand, is +1700 RPM. The ring gear is also +1400 RPM, as determined by the number of teeth in each gear.

Torque is the twisting force of a gear, and the bigger the gear, the higher the torque. However, since the torque is also proportional to the size of the gear, bigger radii result in lower torque. In addition, smaller radii do not move cars faster, so the higher gear ratios do not move at highway speeds. The tradeoff between speed and torque is the gear ratio.

Planetary gears use multiple mechanisms to increase the gear ratio. Those using epicyclic gears have multiple gear sets, including a sun, a ring, and two planets. Moreover, the planetary gears are based on helical, bevel, and spur gears. In general, the higher gear ratios of epicyclic gears are superior to those of planetary gears.

Another example of planetary gears is the compound planet. This gear design has two different-sized gears on either end of a common casting. The large end engages the sun while the smaller end engages the annulus. The compound planets are sometimes necessary to achieve smaller steps in gear ratio. As with any gear, the correct alignment of planet pins is essential for proper operation. If the planets are not aligned properly, it may result in rough running or premature breakdown.

in Saltillo Mexico sales price shop near me near me shop factory supplier Delrin Worm Gear Drive Wheel Duplex Ground Plastic Good Price Ground Shaft Helical Micro for Gearbox Speed Reducer Outdoor Ride Car Spare Bestsupplyer Worm Gear manufacturer best Cost Custom Cheap wholesaler

assures the stability and regularity of the important perform of elements. we offer chromed bar and tubes for hydualic and pheumatic cylinders. The new items include a series of higher-tech and large high quality chains and sprockets and gears, this kind of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, high-pace tooth chains, timing chains, self-lubrication chains, among which have kind higher speed tooth chain for vehicle department dynamic box and aerial chains fill in the blanks of chain in China.

Delrin Worm EPT Travel Wheel Duplex Floor Plastic Excellent Cost Ground Shaft EPTcal EPT for EPTT Speed EPTT Outside Journey Car EPT EPTTEPTer Worm EPT

in Ufa Russian Federation sales price shop near me near me shop factory supplier R Series Inline Helical Geared Motor Gearbox Speed Reducer manufacturer best Cost Custom Cheap wholesaler

Thanks to our extensive item range and wealthy encounters in this market, With EPG brand registered in far more than 70 nations like The united states , Europe , Japan and so on, it has partners amongst planet prime enterprises, this sort of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so forth. In 2008, it was awarded with “Countrywide Export Commodity Inspection-totally free Enterprise”. EPT Parameter

| EPT materials | EPT200 large-power cast iron(R37, R47, R57, R67, R77, R87) |

| EPT substance | EPT250 Large toughness cast iron(R97, R 107, R137, R147, R167) |

| Gear materials | 20CrMnTi |

| Gear Surface area amphardness | HRC58 deg-sixty two deg |

| Gear core hardness | HRC33 deg-seventy eight deg |

| Input/Output shaft substance | 40Cr |

| Equipment Machining precision | Exact grinding 6-five quality |

| Warmth treatment | Carburizing, Quenching and so forth |

| Effectiveness | Up to 92% |

| Sound(Max) | 60-67dB |

| Set up variety | Foot mounted, flange mounted |

| Output type | Sound shaft |

| EPT brand | NSK, SKF, HRB, ZWZ and so on |

| Oil seal manufacturer | NAK, KSK and so on |

| Lubricant | VG220 |

| EPT | IP55, F class |

| EPT shaft | 40Cr, Carburizing, Quenching and so forth |

| Warranty | 12months |

| Shade | Blue, Gray |

| Model | SLR37 | SLR47 | SLR57 | SLR67 | SLR77 | SLR87 | EWR97 | SLR107 | SLR137 | SLR147 | SLR167 |

| Fat | nine | fourteen | 24 | 27 | 33 | 60 | 110 | one hundred fifty | 255 | 365 | 615 |

| Shaft #1060 | 25mm | 30mm | 35mm | 35mm | 40mm | 50mm | 60mm | 70mm | 90mm | 110mm | 120mm |

Application:

Ceramic Market

Glass Market

Foods Market

EPTlurgy Business

Beer amp Consume Market

EPT and dyeing Market

Textile Sector

Warehouse Logoistics Business

EPT operating EPTry

environmental protection gear Market

Leather-based Business

Pharmacy Sector

EPT images:

Deals:

Company Info:

Make contact with:

in Montreal Canada sales price shop near me near me shop factory supplier Worm Wheel Gearbox Speed Reducer Jack Worm Agricultural Planetary Helical Bevel Steering Gear Drive Motor Speed Nmrv Good Quantity Durableworm Gear Reducers manufacturer best Cost Custom Cheap wholesaler

We will give ideal providers and large high quality merchandise with all sincerity. EPG will usually adhere to it business spirit of getting practical, revolutionary, productive and outstanding to make the leading worldwide transmission drive. Keeping in brain that very good support is the key to cooperating with clients, we attempt to satisfy substantial top quality requirements, provide aggressive charges and make certain prompt supply.

Worm Wheel EPT Velocity EPT Jack Worm Agricultural Planetary Helical EPTl Steering Equipment Generate EPT Pace Nmrv Good quantity DurableWorm Gear EPTs

How does a worm gear perform?

How Worm Gears Operate. An electrical motor or engine applies rotational EPT by way of to the worm. EPT worm rotates towards the wheel, and the screw experience pushes on the enamel of the wheel. EPT wheel is pushed against the load.

Can a worm gear go each instructions?

Worm drives can go possibly route, but they want to be created for it. As you can envision, turning the worm shaft unEPTload will create a thrust aEPT the aXiHu (West Lake) Dis.s of the screw. Nonetheless, if you reverse the course the route of thrust will reverse as nicely.

EPT fundamental structure of the worm gear EPT is primarily composed of the worm equipment, the shaft, the bearing, the box body and its components. Can be divided into a few basic structural elements: box, worm gear, bearing and shaft mix. EPT box is the foundation of all the add-ons in the worm equipment EPT. It is an EPTant part that supports the fixed shaft parts, ensures the proper relative position of the EPT elements and supports the load performing on the EPT. EPT major perform of the worm gear is to transmit the movement and EPT between the two staggered shafts.

in Larkana Pakistan sales price shop near me near me shop factory supplier Worm Gear Reducer Box Speed Reducer Jack Worm Agricultural Planetary Helical Bevel Steering Gear Drive Motor Speed Nmrv Good Quantity Durableworm Gear Reducers manufacturer best Cost Custom Cheap wholesaler

We are aiming to meet the calls for of the consumers about the world.. If you need to have any information or samples, make sure you get in touch with us and you will have our soon reply. With several years’ knowledge in these traces, we have been distinguished from other suppliers in China by our advantages in aggressive pricing, on-time supply, prompt responses, on-hand engineering support and very good right after-income solutions.

Worm Gear EPT EPTox Pace EPT Jack Worm Agricultural Planetary Helical EPTl Steering Gear Drive Motor Pace Nmrv Very good quantity DurableWorm Gear EPTs

in Agartala India sales price shop near me near me shop factory supplier High Quality Hard Tooth Surface S K F R Speed Reducer K Series Helical Bevel Gear Reducer K47 Helical Gear Reducer manufacturer best Cost Custom Cheap wholesaler

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

Gear made in China – replacement parts – in Gebze Turkey Reducer Helical Gearbox Gear Units Transmission Gear Geared Motor Speed Reducer Helical Gear Motor Worm Gearbox Reductor Hypoid Reducer with Torque Arm with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 various branches. For much more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

gear reducer helical gearbox equipment models transmission equipment geared motor speed reducer helical equipment motor worm gearbox reductor hypoid reducer with torque arm

hypoid gear box, gear reducer, gear unit, Industrial electrical agitator motor gearbox for mechanical liquid mixer, 90 diploma gearbox

Helical equipment motor, correct angle gearbox, equipment travel speed reducer

| electric motor |

| motor |

| geared motor |

| gear |

| transmission gearbox |

| gear box |

| spare areas |

| equipment motor |

| geared motor |

| transmission |

About us

Quality management

Packing

NON-Regular equipment speed reducer

Normal Gear reducer production

Certificate

Shipping

7-fifteen times

Contact us

The use of authentic gear manufacturer’s (OEM) portion quantities or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our firm and the listed substitution parts contained herein are not sponsored, accredited, or created by the OEM.

China manufacturer & factory supplier for HangZhou in Meerut India EPG professional R17 helical gear speed reducer With high quality best price & service

Company of roller generate chains for electrical power transmission programs from standard industrial to functions in specialized locations this kind of as food processing, large development equipment, and oil field solutions. Available in double pitch travel and common roller chains with one and multiple strand configurations. Specifications incorporate .twenty five to 3 in. chain pitch, .thirteen to 1.88 in. length amongst sidebars, and .09 to .94 in. pin diameter. Obtainable with characteristics this kind of as scenario-hardened and armor-cased pins, pre-pressured procedure, corrosion and shock resistance, and stainless metal components. Gives submit-sale assistance solutions.The team has taken portion in the producing and revising of ISO/TC100 international chain normal several a long time in success and hosted the sixteenth ISO/TC100 International once-a-year conference in 2004.

Overview

Quick Specifics

- Applicable Industries:

-

Manufacturing Plant

- Gearing Arrangement:

-

Helical

- Product Number:

-

Adhering to “Survival by Quality, Growth by Technological innovation & Credit score”, The firm will continually improve solution performance to fulfill the growing consumer specifications in the demanding fashion of work.

R17-R167

PTO Shaft A PTO Adapter will be beneficial when functioning Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could trigger the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 stage hitch.

- Rated Energy:

-

.12kw-160kw

- Product identify:

-

Shanghai Goldgun skilled R17 helical gear speed reducer

- Model No.:

-

R17

- Ratio:

-

three.83 – 8164

- Input electricity ranking:

-

.twelve – .seventy five

- Pernissble torque (N .M):

-

87

- Color:

-

Silver Green Blue

- Certification:

-

ISO9001:2008

- Send inquiry:

-

commercial @goldgun.cn

Source Ability

- Offer Capability:

- 5000 Established/Sets for every Year

Packaging & Shipping

- Packaging Information

- Seaworthy wooden scenario

- Port

- Shanghai ,Ningbo,Shenzhen ,Tianjin ect

On the internet Customization

Item Info

Item Description

| Place of Origin | China |

| Model Identify | 202001EPG |

| Gearing Arrangement | Helical |

| Output Torque | 1.4~22900 |

| Enter Speed | 1400rpm |

| Output Pace | .06-1095rpm |

| China | Zhejiang |

| Model Quantity | R17-R167 |

| Rated Electrical power | .12kw-160kw |

| Item identify | Shanghai Goldgun specialist R17 helical gear velocity reducer |

| Design No. | R17 |

| Ratio | 3.83 – 8164 |

| Enter electricity ranking | .12 – .seventy five |

| Pernissble torque (N .M) | 87 |

| Coloration | Silver Inexperienced Blue |

| Certification | ISO9001:2008 |

| Ship inquiry | professional @goldgun.cn |

Product Screen

Item Screen

Related Goods

EK sequence helical- …

ER sequence helical …

S series Helical – …

CompanyInfo

Business Profile

Solution Process

Manufacturing Approach

Certifications

Certifications

user-described

Cargo & Payment

Our Rewards

A: Your inquiry relevant to our goods or rates will be replied in 24 several hours.

B: Protection of your income location, tips of layout and all your personal details.

C: Greatest quality and aggressive price.

……

faq

FAQ

1) How can I area buy?

A: You can contact us by email about your buy specifics, or location buy on line.

2) How can I shell out you?

A: After you verify our PI, we will request you to spend. T/T (HSBC bank) and Paypal, Western Union are the most usual techniques we are using.

……