Product Description

Model Selection

ZD Leader has a wide range of micro motor production lines in the industry, including DC Motor, AC Motor, Brushless Motor, Planetary Gear Motor, Drum Motor, Planetary Gearbox, RV Reducer and Harmonic Gearbox etc. Through technical innovation and customization, we help you create outstanding application systems and provide flexible solutions for various industrial automation situations.

• Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

• Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

• On Your Need

We can modify standard products or customize them to meet your specific needs.

Detailed Photos

Product Description:

Gear Motor-Torque Table Allowance Torque Unit:Upside (N.m)/Belowside (kgf.cm)

•Gearhead and Intermediate gearhead are sold separately.

•Enter the reduction ratio into the blank() within the model name.

•The speed is calculated by dividing the motor’s synchronous speed by the reduction ratio. The actual speed is 2%~20% less than the displayed value, depending on the size of the load.

•To reduce the speed beyond the reduction ratio in the following table, attach an intermediate gearhead (reduction ratio: 10) between the reducer and motor. In that case, the permissible torque is 8N-m.

|

Type Motor/Gearhead |

Gear Ratio |

3 |

3.6 |

5 |

6 |

7.5 |

9 |

12.5 |

15 |

18 |

25 |

30 |

36 |

50 |

60 |

75 |

90 |

100 |

120 |

150 |

180 |

|

Speed r/min |

1000 |

833 |

600 |

500 |

400 |

333 |

240 |

200 |

166 |

120 |

100 |

83 |

60 |

50 |

40 |

33 |

30 |

25 |

20 |

16 |

|

| Z4D40-90GN(4GN10XK) |

4GN()RC/ 4GN()RT |

0.25 |

0.30 |

0.42 |

0.50 |

0.70 |

0.84 |

1.16 |

1.39 |

1.67 |

2.32 |

2.78 |

3.34 |

4.64 |

5.01 |

6.27 |

7.52 |

8.00 |

8.00 |

8.00 |

8.00 |

|

2.55 |

3.06 |

4.28 |

5.10 |

7.14 |

8.57 |

11.8 |

14.2 |

17.0 |

23.7 |

28.4 |

34.1 |

47.3 |

51.1 |

64.0 |

76.7 |

80.0 |

80.0 |

80.0 |

8.00 |

Dimensions(Unit:mm):

Other Related Products

Click here to find what you are looking for:

Company Profile

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Power Tools |

|---|---|

| Operating Speed: | Constant Speed |

| Structure and Working Principle: | Brushless |

| Certification: | ISO9001, CCC |

| Transport Package: | Cnt |

| Specification: | UL, CE, ISO9001, CCC, RoHS |

| Customization: |

Available

|

|

|---|

Are there innovations or emerging technologies in the field of gear motor design?

Yes, there are several innovations and emerging technologies in the field of gear motor design. These advancements aim to improve the performance, efficiency, compactness, and reliability of gear motors. Here are some notable innovations and emerging technologies in gear motor design:

1. Miniaturization and Compact Design:

Advancements in manufacturing techniques and materials have enabled the miniaturization of gear motors without compromising their performance. Gear motors with compact designs are highly sought after in applications where space is limited, such as robotics, medical devices, and consumer electronics. Innovative approaches like micro-gear motors and integrated motor-gear units are being developed to achieve smaller form factors while maintaining high torque and efficiency.

2. High-Efficiency Gearing:

New gear designs focus on improving efficiency by reducing friction and mechanical losses. Advanced gear manufacturing techniques, such as precision machining and 3D printing, allow for the creation of intricate gear tooth profiles that optimize power transmission and minimize losses. Additionally, the use of high-performance materials, coatings, and lubricants helps reduce friction and wear, improving overall gear motor efficiency.

3. Magnetic Gearing:

Magnetic gearing is an emerging technology that replaces traditional mechanical gears with magnetic fields to transmit torque. It utilizes the interaction of permanent magnets to transfer power, eliminating the need for physical gear meshing. Magnetic gearing offers advantages such as high efficiency, low noise, compactness, and maintenance-free operation. While still being developed and refined, magnetic gearing holds promise for various applications, including gear motors.

4. Integrated Electronics and Controls:

Gear motor designs are incorporating integrated electronics and controls to enhance performance and functionality. Integrated motor drives and controllers simplify system integration, reduce wiring complexity, and allow for advanced control features. These integrated solutions offer precise speed and torque control, intelligent feedback mechanisms, and connectivity options for seamless integration into automation systems and IoT (Internet of Things) platforms.

5. Smart and Condition Monitoring Capabilities:

New gear motor designs incorporate smart features and condition monitoring capabilities to enable predictive maintenance and optimize performance. Integrated sensors and monitoring systems can detect abnormal operating conditions, track performance parameters, and provide real-time feedback for proactive maintenance and troubleshooting. This helps prevent unexpected failures, extend the lifespan of gear motors, and improve overall system reliability.

6. Energy-Efficient Motor Technologies:

Gear motor design is influenced by advancements in energy-efficient motor technologies. Brushless DC (BLDC) motors and synchronous reluctance motors (SynRM) are gaining popularity due to their higher efficiency, better power density, and improved controllability compared to traditional brushed DC and induction motors. These motor technologies, when combined with optimized gear designs, contribute to overall system energy savings and performance improvements.

These are just a few examples of the innovations and emerging technologies in gear motor design. The field is continuously evolving, driven by the need for more efficient, compact, and reliable motion control solutions in various industries. Gear motor manufacturers and researchers are actively exploring new materials, manufacturing techniques, control strategies, and system integration approaches to meet the evolving demands of modern applications.

How do gear motors compare to other types of motors in terms of power and efficiency?

Gear motors can be compared to other types of motors in terms of power output and efficiency. The choice of motor type depends on the specific application requirements, including the desired power level, efficiency, speed range, torque characteristics, and control capabilities. Here’s a detailed explanation of how gear motors compare to other types of motors in terms of power and efficiency:

1. Gear Motors:

Gear motors combine a motor with a gear mechanism to deliver increased torque output and improved control. The gear reduction enables gear motors to provide higher torque while reducing the output speed. This makes gear motors suitable for applications that require high torque, precise positioning, and controlled movements. However, the gear reduction process introduces mechanical losses, which can slightly reduce the overall efficiency of the system compared to direct-drive motors. The efficiency of gear motors can vary depending on factors such as gear quality, lubrication, and maintenance.

2. Direct-Drive Motors:

Direct-drive motors, also known as gearless or integrated motors, do not use a gear mechanism. They provide a direct connection between the motor and the load, eliminating the need for gear reduction. Direct-drive motors offer advantages such as high efficiency, low maintenance, and compact design. Since there are no gears involved, direct-drive motors experience fewer mechanical losses and can achieve higher overall efficiency compared to gear motors. However, direct-drive motors may have limitations in terms of torque output and speed range, and they may require more complex control systems to achieve precise positioning.

3. Stepper Motors:

Stepper motors are a type of gear motor that excels in precise positioning applications. They operate by converting electrical pulses into incremental steps of movement. Stepper motors offer excellent positional accuracy and control. They are capable of precise positioning and can hold a position without power. Stepper motors have relatively high torque at low speeds, making them suitable for applications that require precise control and positioning, such as robotics, 3D printers, and CNC machines. However, stepper motors may have lower overall efficiency compared to direct-drive motors due to the additional power required to overcome the detents between steps.

4. Servo Motors:

Servo motors are another type of gear motor known for their high torque, high speed, and excellent positional accuracy. Servo motors combine a motor, a feedback device (such as an encoder), and a closed-loop control system. They offer precise control over position, speed, and torque. Servo motors are widely used in applications that require accurate and responsive positioning, such as industrial automation, robotics, and camera pan-tilt systems. Servo motors can achieve high efficiency when properly optimized and controlled but may have slightly lower efficiency compared to direct-drive motors due to the additional complexity of the control system.

5. Efficiency Considerations:

When comparing power and efficiency among different motor types, it’s important to consider the specific requirements and operating conditions of the application. Factors such as load characteristics, speed range, duty cycle, and control requirements influence the overall efficiency of the motor system. While direct-drive motors generally offer higher efficiency due to the absence of mechanical losses from gears, gear motors can deliver higher torque output and enhanced control capabilities. The efficiency of gear motors can be optimized through proper gear selection, lubrication, and maintenance practices.

In summary, gear motors offer increased torque and improved control compared to direct-drive motors. However, gear reduction introduces mechanical losses that can slightly impact the overall efficiency of the system. Direct-drive motors, on the other hand, provide high efficiency and compact design but may have limitations in terms of torque and speed range. Stepper motors and servo motors, both types of gear motors, excel in precise positioning applications but may have slightly lower efficiency compared to direct-drive motors. The selection of the most suitable motor type depends on the specific requirements of the application, balancing power, efficiency, speed range, and control capabilities.

How does the gearing mechanism in a gear motor contribute to torque and speed control?

The gearing mechanism in a gear motor plays a crucial role in controlling torque and speed. By utilizing different gear ratios and configurations, the gearing mechanism allows for precise manipulation of these parameters. Here’s a detailed explanation of how the gearing mechanism contributes to torque and speed control in a gear motor:

The gearing mechanism consists of multiple gears with varying sizes, tooth configurations, and arrangements. Each gear in the system engages with another gear, creating a mechanical connection. When the motor rotates, it drives the rotation of the first gear, which then transfers the motion to subsequent gears, ultimately resulting in the output shaft’s rotation.

Torque Control:

The gearing mechanism in a gear motor enables torque control through the principle of mechanical advantage. The gear system utilizes gears with different numbers of teeth, known as gear ratio, to adjust the torque output. When a smaller gear (pinion) engages with a larger gear (gear), the pinion rotates faster than the gear but exerts more force or torque. This results in torque amplification, allowing the gear motor to deliver higher torque at the output shaft while reducing the rotational speed. Conversely, if a larger gear engages with a smaller gear, torque reduction occurs, resulting in higher rotational speed at the output shaft.

By selecting the appropriate gear ratio, the gearing mechanism effectively adjusts the torque output of the gear motor to match the requirements of the application. This torque control capability is essential in applications that demand high torque for heavy lifting or overcoming resistance, as well as applications that require lower torque but higher rotational speed.

Speed Control:

The gearing mechanism also contributes to speed control in a gear motor. The gear ratio determines the relationship between the rotational speed of the input shaft (driven by the motor) and the output shaft. When a gear motor has a higher gear ratio (more teeth on the driven gear compared to the driving gear), it reduces the output speed while increasing the torque. Conversely, a lower gear ratio increases the output speed while reducing the torque.

By choosing the appropriate gear ratio, the gearing mechanism allows for precise speed control in a gear motor. This is particularly useful in applications that require specific speed ranges or variations, such as conveyor systems, robotic movements, or machinery that needs to operate at different speeds for different tasks. The speed control capability of the gearing mechanism enables the gear motor to match the desired speed requirements of the application accurately.

In summary, the gearing mechanism in a gear motor contributes to torque and speed control by utilizing different gear ratios and configurations. It enables torque amplification or reduction, depending on the gear arrangement, allowing the gear motor to deliver the required torque output. Additionally, the gear ratio also determines the relationship between the rotational speed of the input and output shafts, providing precise speed control. These torque and speed control capabilities make gear motors versatile and suitable for a wide range of applications in various industries.

editor by CX 2024-05-17

China Custom [Y2-160m2-2] 15kw Three Phase AC Motor Worm Gear Motor for Industrial Transmission supplier

Product Description

[Y2-160m2-2] 15kw Three Phase AC Motor Worm Gear Motor for Industrial Transmission

Product Parameters

Brief:

Three phase asynchronous motor is totally enclosed and fan-cooling, three-phase squirrel cage induction motor, that is newly designed in conformity with the relevant requirements of IEC standards. These motors have outstanding performance, such as high efficiency, energy-saving, high starting torque, low noise, little vibration, reliable operation and easy maintenance, etc.

They are widely used in many places, where there doesn’t exist combustible, explosive or corrosive gas, and without any special requirements, such as machine tools, pumps, fans, transport machinery, mixer, agriculture machinery and food machinery, etc.

| Frame Size: | 63-355 MM |

| Rated Output: | 0.12-315 KW or 0.15-465 HP |

| Rated Voltage: | 380 V or to be your request |

| Rated Frequency: | 50 Hz / 60 Hz |

| Poles: | 2 / 4 / 6 / 8 / 10 |

| Speed: | 590 -2980 r/min |

| Ambient Temperature: | -15°C-40°C |

| Model of CONEECTION: | Y-Connection for 3 KW motor or less while Delta-Connection for 4 KW motor or more |

| Mounting: | B3; B35; B34; B14; B5; V1 |

| Current: | 1.5-465 A (AC) |

| Duty: | continuous (S1) |

| Insulation Class: | B / F |

| Protection Class: | IP54 |

| Cooling Method: | ICO 141 Standards |

| Altitude: | No more than 1,000 CHINAMFG above sea level |

| Packing: | 63-132 frame be packaged by carton&pallet 160-355 frame be packaged by plywood case |

Our Advantages

HangZhouda motors advantage:

Prompt Quotation.

Competitive Price

Guaranteed Quality

Timely Delivery.

100% Tested.

Sincere and Professional Service.

Outstanding Finishing Surface.

Strictly and Perfect Management is guaranteed for Production.

Specialized in Manufacturing and Supplying a wide range of Electric Motors since year 2002.

Have Rich Experience and Strong ability to Develop New Products.

Have Ability to Design the Products Based on Your Original Samples.

Our promise:

Prompt Reply to Your Inquiry within 24 Hs during Working Days.

Long Life Time Products

Products One Year Guarantee from the Date of Sales.

Professional Service in Handling Your Goods in Daily Communications

Deliver Time about 15-20 days for Normal Models.

Deliver Time about 30 days for New Models CHINAMFG Receiving the New Samples.

Welcome your sincere inquiry about ELECTRIC MOTORS, We look CHINAMFG you to visiting our factory. We remain the best service all the time. Thank you very much.

Detailed Photos

Company Profile

HangZhouda Technology Co., Ltd. is a modern enterprise that integrates scientific research, production, sales, and service. The company has advanced production equipment, first-class testing equipment, professional R&D personnel, and an excellent management team. Multiple products have been patented. And it has 3 subsidiaries: HangZhouda Motor, HangZhouda Welding Machine, and HangZhouda Welding Materials.

The company’s motor products mainly include various series of products such as YBX3, YBX4, YE3, YE4, YBBP, YVF, YBF3, YSF3 three-phase motors, etc. The products have passed 3C certification, CE certification, IS09000-2015 quality management system certification, and have obtained QS production license, EX explosion-proof certificate, export product quality license, etc. The products are exported to both domestic and foreign markets.

The company implements a sustainable development strategy, upholds the business philosophy of “integrity, pragmatism, efficiency, and innovation”, always adheres to the policy of “people-oriented, quality wins”, and establishes a good corporate image with advanced equipment, scientific management, meticulous design, exquisite craftsmanship, and high-quality service. The company is based in the industry and dedicated to society with high standard product quality, discounted prices, and comprehensive and thoughtful services.

FAQ

Q1: Are you a factory or a trading company?

A1: As a manufacturer, we have many years of experience in the development and production of motors and industrial fans

Q2: Do you provide customized services?

A2: Of course, both OEM and ODM are available.

Q3: How to obtain a quotation?

A3: Regarding your purchase request, please leave us a message and we will reply to you within 1 hour of working hours.

Q4: Can I buy 1 as a sample?

A4: Of course.

Q5: How is your quality control?

A5: Our professional QC will inspect the quality during the production process and conduct quality testing before shipment.

Q6: What warranty do you offer?

A6: Within 1 year, during the warranty period, we will provide free easily damaged parts to solve any problems that may occur except for incorrect operation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal |

|---|---|

| Operating Speed: | Constant Speed |

| Number of Stator: | Three-Phase |

| Species: | Y, Y2 Series Three-Phase |

| Rotor Structure: | Winding Type |

| Casing Protection: | Protection Type |

| Customization: |

Available

|

|

|---|

What are the maintenance requirements for gear motors, and how can longevity be maximized?

Gear motors, like any mechanical system, require regular maintenance to ensure optimal performance and longevity. Proper maintenance practices help prevent failures, minimize downtime, and extend the lifespan of gear motors. Here are some maintenance requirements for gear motors and ways to maximize their longevity:

1. Lubrication:

Regular lubrication is essential for gear motors to reduce friction, wear, and heat generation. The gears, bearings, and other moving parts should be properly lubricated according to the manufacturer’s recommendations. Lubricants should be selected based on the motor’s specifications and operating conditions. Regular inspection and replenishment of lubricants, as well as periodic oil or grease changes, should be performed to maintain optimal lubrication levels and ensure long-lasting performance.

2. Inspection and Cleaning:

Regular inspection and cleaning of gear motors are crucial for identifying any signs of wear, damage, or contamination. Inspecting the gears, bearings, shafts, and connections can help detect any abnormalities or misalignments. Cleaning the motor’s exterior and ventilation channels to remove dust, debris, or moisture buildup is also important in preventing malfunctions and maintaining proper cooling. Any loose or damaged components should be repaired or replaced promptly.

3. Temperature and Environmental Considerations:

Monitoring and controlling the temperature and environmental conditions surrounding gear motors can significantly impact their longevity. Excessive heat can degrade lubricants, damage insulation, and lead to premature component failure. Ensuring proper ventilation, heat dissipation, and avoiding overloading the motor can help manage temperature effectively. Similarly, protecting gear motors from moisture, dust, chemicals, and other environmental contaminants is vital to prevent corrosion and damage.

4. Load Monitoring and Optimization:

Monitoring and optimizing the load placed on gear motors can contribute to their longevity. Operating gear motors within their specified load and speed ranges helps prevent excessive stress, overheating, and premature wear. Avoiding sudden and frequent acceleration or deceleration, as well as preventing overloading or continuous operation near the motor’s maximum capacity, can extend its lifespan.

5. Alignment and Vibration Analysis:

Proper alignment of gear motor components, such as gears, couplings, and shafts, is crucial for smooth and efficient operation. Misalignment can lead to increased friction, noise, and premature wear. Regularly checking and adjusting alignment, as well as performing vibration analysis, can help identify any misalignment or excessive vibration that may indicate underlying issues. Addressing alignment and vibration problems promptly can prevent further damage and maximize the motor’s longevity.

6. Preventive Maintenance and Regular Inspections:

Implementing a preventive maintenance program is essential for gear motors. This includes establishing a schedule for routine inspections, lubrication, and cleaning, as well as conducting periodic performance tests and measurements. Following the manufacturer’s guidelines and recommendations for maintenance tasks, such as belt tension checks, bearing replacements, or gear inspections, can help identify and address potential issues before they escalate into major failures.

By adhering to these maintenance requirements and best practices, the longevity of gear motors can be maximized. Regular maintenance, proper lubrication, load optimization, temperature control, and timely repairs or replacements of worn components contribute to the reliable operation and extended lifespan of gear motors.

Can you explain the role of backlash in gear motors and how it’s managed in design?

Backlash plays a significant role in gear motors and is an important consideration in their design and operation. Backlash refers to the slight clearance or play between the teeth of gears in a gear system. It affects the precision, accuracy, and responsiveness of the gear motor. Here’s an explanation of the role of backlash in gear motors and how it is managed in design:

1. Role of Backlash:

Backlash in gear motors can have both positive and negative effects:

- Compensation for Misalignment: Backlash can help compensate for minor misalignments between gears, shafts, or the load. It allows a small amount of movement before engaging the next set of teeth, reducing the risk of damage due to misalignment. This can be particularly beneficial in applications where precise alignment is challenging or subject to variations.

- Negative Impact on Accuracy and Responsiveness: Backlash can introduce a delay or “dead zone” in the motion transmission. When changing the direction of rotation or reversing the load, the gear teeth must first overcome the clearance or play before engaging in the opposite direction. This delay can reduce the overall accuracy, responsiveness, and repeatability of the gear motor, especially in applications that require precise positioning or rapid changes in direction or speed.

2. Managing Backlash in Design:

Designers employ various techniques to manage and minimize backlash in gear motors:

- Tight Manufacturing Tolerances: Proper manufacturing techniques and tight tolerances can help minimize backlash. Precision machining and quality control during the production of gears and gear components ensure closer tolerances, reducing the amount of play between gear teeth.

- Preload or Pre-tensioning: Applying a preload or pre-tensioning force to the gear system can help reduce backlash. This technique involves introducing an initial force or tension that eliminates the clearance between gear teeth. It ensures immediate contact and engagement of the gear teeth, minimizing the dead zone and improving the overall responsiveness and accuracy of the gear motor.

- Anti-Backlash Gears: Anti-backlash gears are designed specifically to minimize or eliminate backlash. They typically feature modifications to the gear tooth profile, such as modified tooth shapes or special tooth arrangements, to reduce clearance. Anti-backlash gears can be used in gear motor designs to improve precision and minimize the effects of backlash.

- Backlash Compensation: In some cases, backlash compensation techniques can be employed. These techniques involve monitoring the position or movement of the load and applying control algorithms to compensate for the backlash. By accounting for the clearance and adjusting the control signals accordingly, the effects of backlash can be mitigated, improving accuracy and responsiveness.

3. Application-Specific Considerations:

The management of backlash in gear motors should be tailored to the specific application requirements:

- Positioning Accuracy: Applications that require precise positioning, such as robotics or CNC machines, may require tighter backlash control to ensure accurate and repeatable movements.

- Dynamic Response: Applications that involve rapid changes in direction or speed, such as high-speed automation or servo control systems, may require reduced backlash to maintain responsiveness and minimize overshoot or lag.

- Load Characteristics: The nature of the load and its impact on the gear system should be considered. Heavy loads or applications with significant inertial forces may require additional backlash management techniques to maintain stability and accuracy.

In summary, backlash in gear motors can affect precision, accuracy, and responsiveness. While it can compensate for misalignments, backlash may introduce delays and reduce the overall performance of the gear motor. Designers manage backlash through tight manufacturing tolerances, preload techniques, anti-backlash gears, and backlash compensation methods. The management of backlash depends on the specific application requirements, considering factors such as positioning accuracy, dynamic response, and load characteristics.

In which industries are gear motors commonly used, and what are their primary applications?

Gear motors find widespread use in various industries due to their versatility, reliability, and ability to provide controlled mechanical power. They are employed in a wide range of applications that require precise power transmission and speed control. Here’s a detailed explanation of the industries where gear motors are commonly used and their primary applications:

1. Robotics and Automation:

Gear motors play a crucial role in robotics and automation industries. They are used in robotic arms, conveyor systems, automated assembly lines, and other robotic applications. Gear motors provide the required torque, speed control, and directional control necessary for the precise movements and operations of robots. They enable accurate positioning, gripping, and manipulation tasks in industrial and commercial automation settings.

2. Automotive Industry:

The automotive industry extensively utilizes gear motors in various applications. They are used in power windows, windshield wipers, HVAC systems, seat adjustment mechanisms, and many other automotive components. Gear motors provide the necessary torque and speed control for these systems, enabling smooth and efficient operation. Additionally, gear motors are also utilized in electric and hybrid vehicles for powertrain applications.

3. Manufacturing and Machinery:

Gear motors find wide application in the manufacturing and machinery sector. They are used in conveyor belts, packaging equipment, material handling systems, industrial mixers, and other machinery. Gear motors provide reliable power transmission, precise speed control, and torque amplification, ensuring efficient and synchronized operation of various manufacturing processes and machinery.

4. HVAC and Building Systems:

In heating, ventilation, and air conditioning (HVAC) systems, gear motors are commonly used in damper actuators, control valves, and fan systems. They enable precise control of airflow, temperature, and pressure, contributing to energy efficiency and comfort in buildings. Gear motors also find applications in automatic doors, blinds, and gate systems, providing reliable and controlled movement.

5. Marine and Offshore Industry:

Gear motors are extensively used in the marine and offshore industry, particularly in propulsion systems, winches, and cranes. They provide the required torque and speed control for various marine operations, including steering, anchor handling, cargo handling, and positioning equipment. Gear motors in marine applications are designed to withstand harsh environments and provide reliable performance under demanding conditions.

6. Renewable Energy Systems:

The renewable energy sector, including wind turbines and solar tracking systems, relies on gear motors for efficient power generation. Gear motors are used to adjust the rotor angle and position in wind turbines, optimizing their performance in different wind conditions. In solar tracking systems, gear motors enable the precise movement and alignment of solar panels to maximize sunlight capture and energy production.

7. Medical and Healthcare:

Gear motors have applications in the medical and healthcare industry, including in medical equipment, laboratory devices, and patient care systems. They are used in devices such as infusion pumps, ventilators, surgical robots, and diagnostic equipment. Gear motors provide precise control and smooth operation, ensuring accurate dosing, controlled movements, and reliable functionality in critical medical applications.

These are just a few examples of the industries where gear motors are commonly used. Their versatility and ability to provide controlled mechanical power make them indispensable in numerous applications requiring torque amplification, speed control, directional control, and load distribution. The reliable and efficient power transmission offered by gear motors contributes to the smooth and precise operation of machinery and systems in various industries.

![China Custom [Y2-160m2-2] 15kw Three Phase AC Motor Worm Gear Motor for Industrial Transmission supplier](https://img.hzpt.com/img/motor/ac-motor-L1.webp)

![China Custom [Y2-160m2-2] 15kw Three Phase AC Motor Worm Gear Motor for Industrial Transmission supplier](https://img.hzpt.com/img/motor/ac-motor-L2.webp)

editor by CX 2024-03-28

in Abakaliki Nigeria sales price shop near me near me shop factory supplier Diameter 83mm 12V 24V PMDC Planetary Gear Motor for Industrial Automation manufacturer best Cost Custom Cheap wholesaler

With in depth requirments, we can also develop your particular created product. In this way, our products have continued to obtain market acceptance and customers gratification over the past couple of a long time. Our items are made by modern computerized equipment and equipment. Diameter 83mm 12V 24V PMDC Planetary Gear EPT for EPT EPT

one.EPT requirements:

1. Planet EPT motor measurement: From dia. 22mm to dia. 83mm

two. Fit for small measurement large output EPT gear.

3. The specifications can be made in accordance to the customer’s specifications!

4. The motor have minimal sound,EPT daily life,substantial torque.

five. The motor can include encoEPT

six.Common apps: Laminator, Paper Shredder, Rotating Xmas Tree Stand, fan, electric powered oven, grill.

We also can modify dc motor specs and output shaft dimension in accordance to your EPT requirement.

Welcome to purchase DC motor!

2.Production Circulation

three.Business Data

In recent ten a long time, EPTRY has been committed to the manufacture of the motor products and the primary items can be categorised into the subsequent sequence, particularly DC motor, DC EPT motor, AC motor, AC EPT motor, Stepper motor, Stepper EPT motor, Servo motor and EPT actuator collection.

Our motor products are widely applied in the fields of aerospace business, automotive business, finXiHu (West Lake) Dis.Hu (West Lake) Dis.al tools, EPT EPT, EPT EPT and robotics, healthcare tools, office products, EPT EPTry and EPT business, providing customers reputable tailored remedies for driving and managing.

four.Our Solutions

1). EPT Service:

|

Swift Reply |

All enquiry or e-mail be replied in twelve hours, no hold off for your business. |

|

Skilled Group |

Concerns about items will be replied professionally, just, greatest suggestions to you. |

|

Short EPT time |

Sample or modest orEPTsent in seven-fifteen times, bulk or custom-made orEPTabout 30 days. |

|

Payment Selection |

T/T, Western Union,, L/C, and so forth, straightforward for your organization. |

|

Prior to shipment |

EPTke photos, send to customers for affirmation. Only verified, can be transported out. |

|

Language Selection |

In addition to EPT, you can use your possess language by e-mail, then we can translate it. |

two). Customization Service:

EPT specification(no-load velocity , voltage, torque , diameter, sounds, life, testing) and shaft length can be tailor-produced according to customer’s specifications.

5.Deal amp EPT

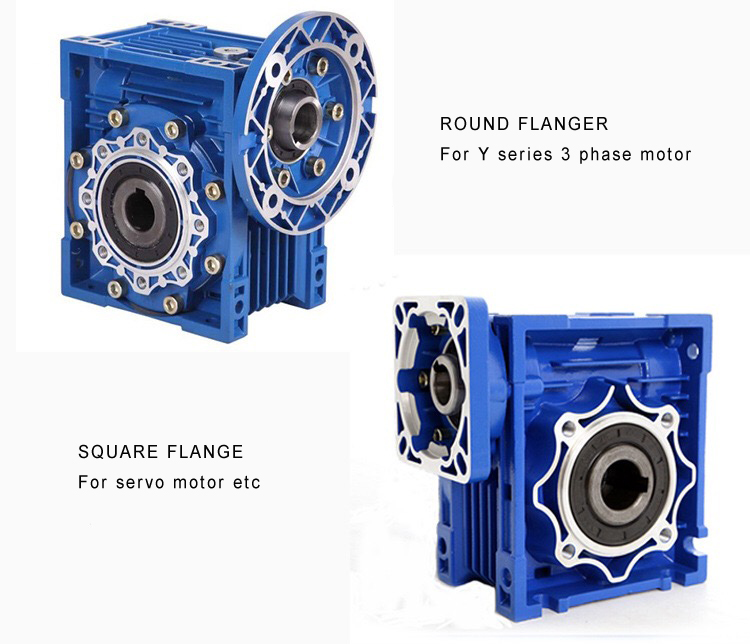

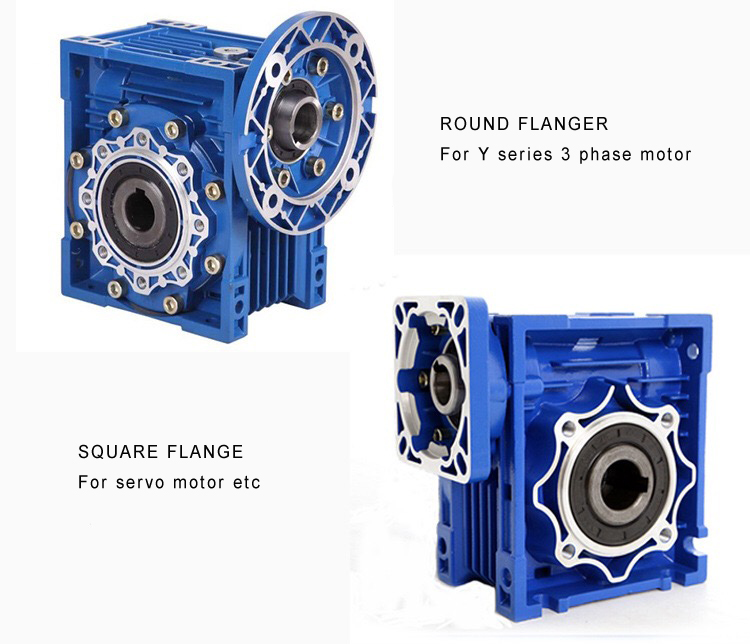

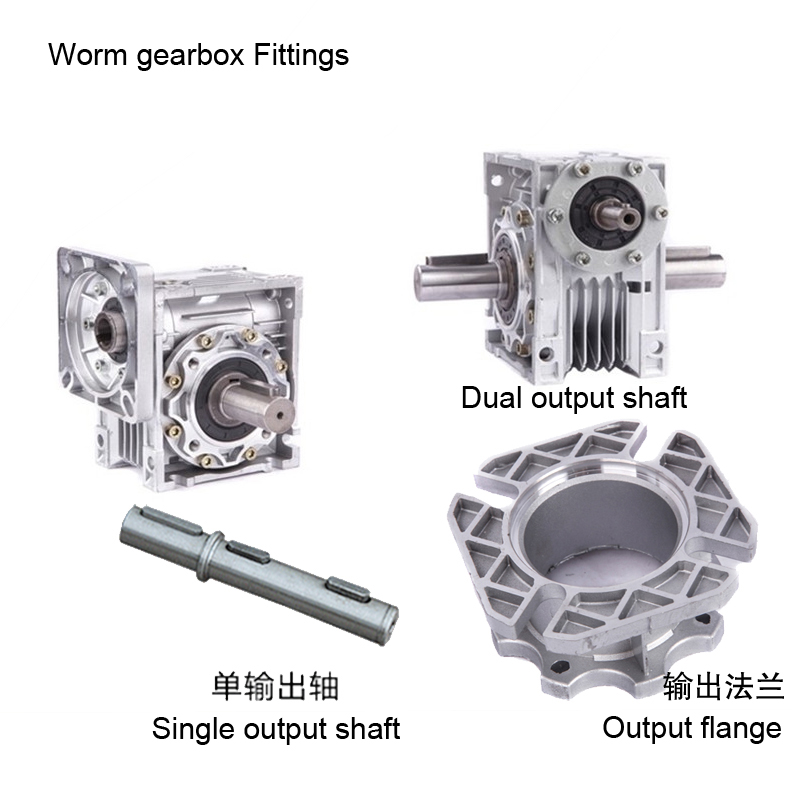

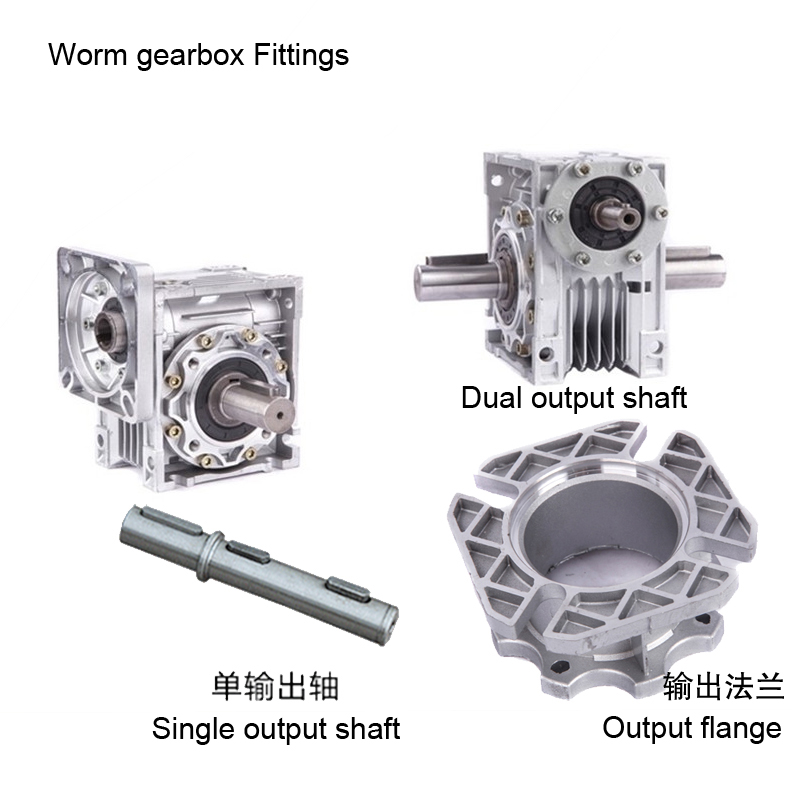

Best China manufacturer & factory Worm in Muzaffarpur India gear industrial sewing machine speed reducer flange mounted worm gearbox nmrv40 reducer with motor With high quality best price

With EPG brand name registered in much more than 70 international locations like America , Europe , Japan and so on, it has companions among planet best enterprises, this kind of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so forth.

Overview

Swift Details

- Relevant Industries:

-

Production Plant

- Model Name:

-

OEM

- Merchandise NO:

-

SYF

- Design Variety:

-

NMRV

- Solution Key phrases:

-

rv gearbox

- Shade:

-

Blue/Silver

- Product name:

-

Electrical power Transmission

- Software:

-

Stepper Motor

- Bearing:

-

NSK

- Certification:

-

ISO9001

- Ratio:

-

five-one hundred

- Mounting Placement:

-

Foot Mounted. Flange Mounted

Packaging & Delivery

-

Lead Time

: -

Quantity(Items) 1 – one hundred >100 Est. Time(days) 2 To be negotiated

On-line Customization

Mounting Dimension

The merchandise are broadly utilized in the producing equipments of all sorts of industries inside and outside China. They are the best choices for these days contemporary facilities of mechanical minimizing drive control to understand huge twisting length, large equipment ratio, little noise, high performance and security.

|

Model: |

NMRV025, 030, 040, 050, 063, 075, 090, a hundred and ten, a hundred thirty, 150 |

|

Ratio: |

1:5,7.5,ten,15,20,25,thirty,40,50,sixty,eighty,100 |

|

Shade: |

Blue, Silver Or On Consumer Ask for |

|

Sounds: |

reduced noise (<50DB) |

|

Edge: |

Efficient and secure functioning |

|

Materials: |

Housing: Die-Solid Aluminum Alloy |

|

Worm Gear-Bronze 9-4# |

|

|

Worm-20CrMnTi with carburizing and quenching, area harness is 56-62HRC |

|

|

Shaft-chromium metal-forty five# |

|

|

Packing: |

Carton and Wood Situation |

|

Bearing: |

C&U Bearing |

|

Seal: |

NAK SKF |

|

Certificate: |

ISO9001,CE,3C,OEM |

|

Guarantee: |

twelve months |

|

Input Electrical power: |

.06kw, .09kw, .12kw, .18kw, .25kw, .37kw, .55kw, .75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

|

Usages: |

Industrial Machine: Foodstuff Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

|

Lubricant: |

Synthetic & Mineral |

Firm profile

HangZhou EPT Team – 1 of the greatest gearbox producer in China – Electromechanical Services Co. Ltd

HangZhou EPT Team – one of the greatest gearbox company in China – Electromechanical Products Co., Ltd.is a present enterprise integrating development, style, generation and product sales,Principal promoting items consist of reducer motor,h2o pump,building equipment and components,bearings,components and electrical products,plastic merchandise,Labour security equipment.Our organization constantly adhere to the operation concept which is made up of individuals-oriented, innovation as the soul,be geared up for threat in times of peace, unremitting……

Item Deseription

Solitary Phase Worm Gear Reducer.

The reducer which model is twenty five~ninety produced of Aluminum alloy die-casting box,good hunting in physical appearance,compact in framework,rust proofing on area and small quantity to save mounting room.

It could be explained that the conditions under which irreversibility can come about are as follows: The reducer design of a hundred and ten~150 is produced of cast iron which casted with Aluminum mould.It`s good looking and strong, and can be utilised via the setting of multi-azimuth.

Good radiating characterstic sales opportunities protected and dependability,and high effectiveness for utilizing.

The sturdy ability of loading guarantee steady transmission,make significantly less vibration and sound.

Differs of connecting composition for electricity input and torque output meet up with various call for-meritsthe design of box define and the established of foot hole with excellent versality is apt to a lot of types of mounting.

The NMRV worm gearbox is new generation of goods by our manufacturing unit on the foundation of perfecting WJ series items with compromise of innovative engineering both at house and overseas.It really is apprearance adopts sophisticated sq. box structure.It really is outer body is created of higher high quality aluminium alloy die casting into forming.It’s modest in quantity,light excess weight,large in radiating performance,huge in output torque,sleek in working and reduced sound.It’s suitbale for all positions.

Strategy for product picked

You should realize the adhering to at first in purchase to delect the model of RV speed reducer properly.

– Loading issue

– Speed scope or ratio in application

– Operating condition and environment

– Set up space

Application region

Certifications

Comprehensive Images

Packing & Shipping

|

Packaging |

|

|

Measurement |

500 (L) * 500 (W) * 400 (D) |

|

Bodyweight |

1.2 T |

|

Packaging Specifics |

The typical package is picket box(Measurement: L*W*H). If export to european international locations,the picket box will be fumigated.If container is way too tigher,we will use pe movie for packing or pack it accordingClose up of two yokes with the common joint. Be aware the slight oozing of grease from the UJ seal finishes, the clump of grease is from inside the yoke splined shaft area –Generate (outer) yoke has a woman (usual spline) gap and “Y” condition conclude that is the universal joint (UJ) mount. –UJ is a cross formed casting obtaining roller bearings enclosed with caps at all four points and is held into the yoke with 4 “C” clips –Internal yoke and travel shaft is an additional yoke welded to the generate stop, of the push shaft. –Pushed shaft and internal yoke is the driven shaft that rides inside of the travel shaft and has a yoke welded at the driven finish –UJ yet another UJ as above to buyers unique request. |

|

Packaging |

|

|

Dimensions |

five hundred (L) * 500 (W) * four hundred (D) |

|

Weight |

one.2 T |

|

Packaging Information |

The standard package deal is wooden box(Dimensions: L*W*H). If export to european international locations,the picket box will be fumigated.If container is as well tigher,we will use pe film for packing or pack it according to customers special ask for. |

FAQ

Q1: Are you trading firm or manufacturer ?

A: We are a producer in ZheJiang China.welcome to our factory to have a go to.

Q2: How we decide on models and requirements?

A:You can electronic mail us the collection name & code (for illustration: WJ series worm gearbox) as effectively as need particulars, this sort of as motor energy, output pace or ratio, support issue or your application…as considerably info as achievable. If you can source some images or drawings, it is better.

Q3: How is your cost? Can you provide any discount?

A: We will give the best price we can base on your requirements and the portions.

Q4: How prolonged should I hold out for the feedback right after I ship the enquiry?

A: Within 12 several hours.

Q5: What is your solution guarantee interval?

A:We offOur merchandise is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The usa, Thailand, Pakistan, Indonesia, a lot more than sixty nations around the world and regions.er one yr guarantee given that the vessel departure date left China.

Q6: What industries are your gearboxes being utilised?

A:Our gearboxes are commonly utilized to metallurgical tools, mining tools, automation tools, foodstuff machinery, packaging tools, tobacco tools and so on.

Get in touch with us

Cellular: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Insert:No.789 ShenHua Street, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT Group – a single of the most significant gearbox company in China – Electromechanical Facilities Co. Ltd.