Product Description

3 Phase AC Reducer Motor 1/2hp 220V 380V 400W Gear Precision Foot Mounted Reducer Motor

CV and CH series motor can be designed as Single phase and 3 phases type. And power range is from 0.1KW to 3.7KW. The motor can be mounted with brake, and brake type is No excitation type. Material of gears is advanced special alloy steel and all gears are carburizing hardening. This gear motor has been added with senior lubricants, and no needs to added lubricants again.

Helical gear reducer has the characteristics of strong versatility, good combination, and strong bearing capacity, and has the advantages of easy access to various transmission ratios, high efficiency, small vibration, and high allowable axial and radial loads.

This series of products can not only be used in combination with various reducers and vibrators to meet the requirements, but also has the advantage of localization of related transmission equipment.

Mostly used in metallurgy, sewage treatment,chemical, pharmaceutical and other industries.

| Type | CH series three phase or single phase ac motors for industrial use | |

| Voltage | 220VAC, 380VAC, 415VAC | |

| Power range | Power range is 0.1KW to 3.7KW | |

| Output Speed | Speed range is from 7rpm to 500rpm | |

| Phase | Single phase and 3phases for choice | |

| Gears | Special alloy steel and high precise gears | |

| Grease | Good grease and no need add grease during using | |

| Cooling | Full closed fan | |

| USE | This motor is widely used in packing machine, textil machine |

motor is widely used in mix machine,elevator, conveyor,etc. |

| OEM Service | We offer OEM service. | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Bevel Gear |

| Step: | Three-Step |

| Samples: |

US$ 70/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about gear motors and their applications?

Individuals seeking to learn more about gear motors and their applications have access to various reliable resources that provide valuable information and insights. Here are some sources where individuals can find reliable information about gear motors:

1. Manufacturer Websites:

Manufacturer websites are a primary source of information about gear motors. Gear motor manufacturers often provide detailed product specifications, application guides, technical documentation, and educational materials on their websites. These resources offer insights into different gear motor types, features, performance characteristics, and application considerations. Manufacturer websites are a reliable and convenient starting point for learning about gear motors.

2. Industry Associations and Organizations:

Industry associations and organizations related to mechanical engineering, automation, and motion control often have resources and publications dedicated to gear motors. These organizations provide technical articles, whitepapers, industry standards, and guidelines related to gear motor design, selection, and application. Examples of such associations include the American Gear Manufacturers Association (AGMA), International Electrotechnical Commission (IEC), and Institute of Electrical and Electronics Engineers (IEEE).

3. Technical Publications and Journals:

Technical publications and journals focused on engineering, robotics, and motion control are valuable sources of in-depth knowledge about gear motors. Publications like IEEE Transactions on Industrial Electronics, Mechanical Engineering magazine, or Motion System Design magazine often feature articles, case studies, and research papers on gear motor technology, advancements, and applications. These publications provide authoritative and up-to-date information from industry experts and researchers.

4. Online Forums and Communities:

Online forums and communities dedicated to engineering, robotics, and automation can be excellent resources for discussions, insights, and practical experiences related to gear motors. Websites like Stack Exchange, engineering-focused subreddits, or specialized forums provide platforms for individuals to ask questions, share knowledge, and engage in discussions with professionals and enthusiasts in the field. Participating in these communities allows individuals to learn from real-world experiences and gain practical insights.

5. Educational Institutions and Courses:

Technical colleges, universities, and vocational training centers often offer courses or programs in mechanical engineering, mechatronics, or automation that cover gear motor fundamentals and applications. These educational institutions provide comprehensive curricula, textbooks, and lecture materials that can serve as reliable resources for individuals interested in learning about gear motors. Additionally, online learning platforms like Coursera, Udemy, or LinkedIn Learning offer courses on topics related to gear motors and motion control.

6. Trade Shows and Exhibitions:

Attending trade shows, exhibitions, and industry conferences related to automation, robotics, or motion control provides opportunities to learn about the latest advancements in gear motor technology. These events often feature product demonstrations, technical presentations, and expert panels where individuals can interact with gear motor manufacturers, industry experts, and other professionals. It’s a great way to stay updated on the latest trends, innovations, and applications of gear motors.

When seeking reliable resources, it’s important to consider the credibility of the source, the expertise of the authors, and the relevance to the specific area of interest. By leveraging these resources, individuals can gain a comprehensive understanding of gear motors and their applications, from basic principles to advanced topics, enabling them to make informed decisions and effectively utilize gear motors in their projects or applications.

Can you explain the role of backlash in gear motors and how it’s managed in design?

Backlash plays a significant role in gear motors and is an important consideration in their design and operation. Backlash refers to the slight clearance or play between the teeth of gears in a gear system. It affects the precision, accuracy, and responsiveness of the gear motor. Here’s an explanation of the role of backlash in gear motors and how it is managed in design:

1. Role of Backlash:

Backlash in gear motors can have both positive and negative effects:

- Compensation for Misalignment: Backlash can help compensate for minor misalignments between gears, shafts, or the load. It allows a small amount of movement before engaging the next set of teeth, reducing the risk of damage due to misalignment. This can be particularly beneficial in applications where precise alignment is challenging or subject to variations.

- Negative Impact on Accuracy and Responsiveness: Backlash can introduce a delay or “dead zone” in the motion transmission. When changing the direction of rotation or reversing the load, the gear teeth must first overcome the clearance or play before engaging in the opposite direction. This delay can reduce the overall accuracy, responsiveness, and repeatability of the gear motor, especially in applications that require precise positioning or rapid changes in direction or speed.

2. Managing Backlash in Design:

Designers employ various techniques to manage and minimize backlash in gear motors:

- Tight Manufacturing Tolerances: Proper manufacturing techniques and tight tolerances can help minimize backlash. Precision machining and quality control during the production of gears and gear components ensure closer tolerances, reducing the amount of play between gear teeth.

- Preload or Pre-tensioning: Applying a preload or pre-tensioning force to the gear system can help reduce backlash. This technique involves introducing an initial force or tension that eliminates the clearance between gear teeth. It ensures immediate contact and engagement of the gear teeth, minimizing the dead zone and improving the overall responsiveness and accuracy of the gear motor.

- Anti-Backlash Gears: Anti-backlash gears are designed specifically to minimize or eliminate backlash. They typically feature modifications to the gear tooth profile, such as modified tooth shapes or special tooth arrangements, to reduce clearance. Anti-backlash gears can be used in gear motor designs to improve precision and minimize the effects of backlash.

- Backlash Compensation: In some cases, backlash compensation techniques can be employed. These techniques involve monitoring the position or movement of the load and applying control algorithms to compensate for the backlash. By accounting for the clearance and adjusting the control signals accordingly, the effects of backlash can be mitigated, improving accuracy and responsiveness.

3. Application-Specific Considerations:

The management of backlash in gear motors should be tailored to the specific application requirements:

- Positioning Accuracy: Applications that require precise positioning, such as robotics or CNC machines, may require tighter backlash control to ensure accurate and repeatable movements.

- Dynamic Response: Applications that involve rapid changes in direction or speed, such as high-speed automation or servo control systems, may require reduced backlash to maintain responsiveness and minimize overshoot or lag.

- Load Characteristics: The nature of the load and its impact on the gear system should be considered. Heavy loads or applications with significant inertial forces may require additional backlash management techniques to maintain stability and accuracy.

In summary, backlash in gear motors can affect precision, accuracy, and responsiveness. While it can compensate for misalignments, backlash may introduce delays and reduce the overall performance of the gear motor. Designers manage backlash through tight manufacturing tolerances, preload techniques, anti-backlash gears, and backlash compensation methods. The management of backlash depends on the specific application requirements, considering factors such as positioning accuracy, dynamic response, and load characteristics.

How does the gearing mechanism in a gear motor contribute to torque and speed control?

The gearing mechanism in a gear motor plays a crucial role in controlling torque and speed. By utilizing different gear ratios and configurations, the gearing mechanism allows for precise manipulation of these parameters. Here’s a detailed explanation of how the gearing mechanism contributes to torque and speed control in a gear motor:

The gearing mechanism consists of multiple gears with varying sizes, tooth configurations, and arrangements. Each gear in the system engages with another gear, creating a mechanical connection. When the motor rotates, it drives the rotation of the first gear, which then transfers the motion to subsequent gears, ultimately resulting in the output shaft’s rotation.

Torque Control:

The gearing mechanism in a gear motor enables torque control through the principle of mechanical advantage. The gear system utilizes gears with different numbers of teeth, known as gear ratio, to adjust the torque output. When a smaller gear (pinion) engages with a larger gear (gear), the pinion rotates faster than the gear but exerts more force or torque. This results in torque amplification, allowing the gear motor to deliver higher torque at the output shaft while reducing the rotational speed. Conversely, if a larger gear engages with a smaller gear, torque reduction occurs, resulting in higher rotational speed at the output shaft.

By selecting the appropriate gear ratio, the gearing mechanism effectively adjusts the torque output of the gear motor to match the requirements of the application. This torque control capability is essential in applications that demand high torque for heavy lifting or overcoming resistance, as well as applications that require lower torque but higher rotational speed.

Speed Control:

The gearing mechanism also contributes to speed control in a gear motor. The gear ratio determines the relationship between the rotational speed of the input shaft (driven by the motor) and the output shaft. When a gear motor has a higher gear ratio (more teeth on the driven gear compared to the driving gear), it reduces the output speed while increasing the torque. Conversely, a lower gear ratio increases the output speed while reducing the torque.

By choosing the appropriate gear ratio, the gearing mechanism allows for precise speed control in a gear motor. This is particularly useful in applications that require specific speed ranges or variations, such as conveyor systems, robotic movements, or machinery that needs to operate at different speeds for different tasks. The speed control capability of the gearing mechanism enables the gear motor to match the desired speed requirements of the application accurately.

In summary, the gearing mechanism in a gear motor contributes to torque and speed control by utilizing different gear ratios and configurations. It enables torque amplification or reduction, depending on the gear arrangement, allowing the gear motor to deliver the required torque output. Additionally, the gear ratio also determines the relationship between the rotational speed of the input and output shafts, providing precise speed control. These torque and speed control capabilities make gear motors versatile and suitable for a wide range of applications in various industries.

editor by CX 2024-04-24

China High Precision Round Flange Planetary Reducer Gearbox Stepping Servo Motor 60 Double Stage with high quality

Merchandise Description

PLANETX planetary decrease

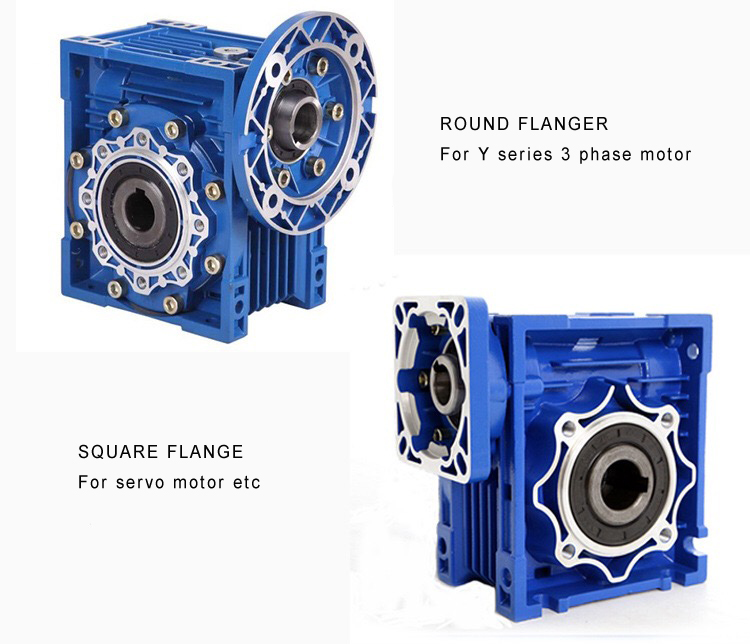

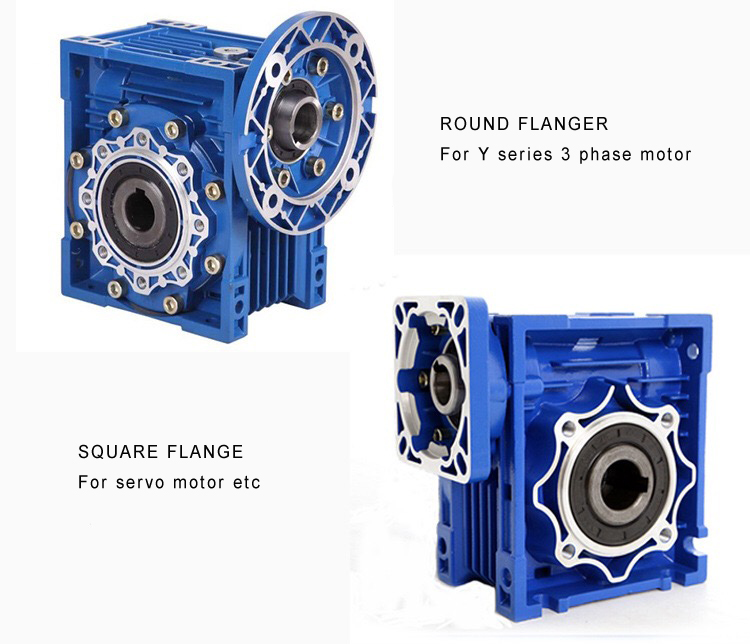

Planetary reducer square flange:

Planetary reducer is commonly employed in industrial goods thanks to its little measurement, gentle fat, massive torque, vast velocity ratio variety, higher rigidity, large precision, substantial transmission effectiveness, routine maintenance totally free and other qualities.

The planetary reducer framework is composed of a sunshine equipment and a planet gear to kind an exterior mesh, and a world gear and an inside gear ring to form an internal mesh, so that the earth equipment can realize revolution even though realizing self rotation and maximum transmission of guarantee power The minimal velocity ratio of single-phase reduction is 3, and the optimum velocity ratio is typically not much more than 10. Widespread reduction ratios are 3, 4, 5, 6, 7, 8, and ten. The variety of reducer stages is usually not much more than 3, and the pace ratio is not far more than 1.

Most planetary reducers are employed with servo motors to minimize pace, improve torque, boost inertia, and make certain return accuracy (the larger the return precision, the increased the value). The greatest rated enter velocity of planetary reducers can achieve 12000 rpm (based on the dimension of the reducer alone, the greater the reducer, the smaller the rated input velocity), and the running temperature is normally in between – 40 ºC and 120 ºC.

Large Performance Planetary Equipment Motor Precision Speed Reducer WAB060 Design Planetary Gearbox

1.Planetary provider and output shaft are intergrated composition to guarantee maximum torsional rigidity. 2.Planetary wheel with complete needle style, boost the make contact with spot to enhance the rigidity and output torque. 3.The Equipment adopts lower carbon alloy steel, via carburizing and quenching, surface area hardness is HRC62, anti-effect and robust abrasion resistance. 4.Gears refer to foreign imported software program-assisted design to obtain the very best tooth shape to decrease sounds. 5.The enter terminal is related to the motor shaft in a double-tight way to obtain the greatest clamping drive and zero backlash electrical power transmission. 6.Adopt spiral bevel equipment style, allow substantial output torque, much more than thirty% increased than straight bevel equipment. 7.High tolerance enter speed, much more than 8 occasions greater than straight bevel gear input. 8.The meshing tooth imprint of spiral bevel gear has been optimized by the best possible design, and the speak to tooth floor load is uniform, and long running life. 9.Bevel gears are meshed by optimum movement mistake examination and stringent method handle to guarantee large precision managing backlash. ten.IP65, anti-dust, anti-h2o low backlash, <3arcmin low noise, <58dB 11.high efficiency(96%)Gear grinding processeasy motor mountinglife-time lubricationvarious figure diameters.

Q: How to get a swift quote

A: Please offer the adhering to info when contacting us

- Motor brand

- Motor design

- Motor dimension drawing

- What is the equipment ratio

Q: How extended is your shipping day

A: We all put in it now, but it takes 3-5 days if it is not non-common. Non normal 10-fifteen times, relying on the distinct scenario

Q:Do you give samples, cost-free or extra

A: A: You can reserve 1 1st, and buy it on demand

|

US $48 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Any |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | 1-3 |

|

US $48 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Any |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | 1-3 |

Dynamic Modeling of a Planetary Motor

A planetary gear motor consists of a series of gears rotating in perfect synchrony, allowing them to deliver torque in a higher output capacity than a spur gear motor. Unlike the planetary motor, spur gear motors are simpler to build and cost less, but they are better for applications requiring lower torque output. That is because each gear carries the entire load. The following are some key differences between the two types of gearmotors.

planetary gear system

A planetary gear transmission is a type of gear mechanism that transfers torque from one source to another, usually a rotary motion. Moreover, this type of gear transmission requires dynamic modeling to investigate its durability and reliability. Previous studies included both uncoupled and coupled meshing models for the analysis of planetary gear transmission. The combined model considers both the shaft structural stiffness and the bearing support stiffness. In some applications, the flexible planetary gear may affect the dynamic response of the system.

In a planetary gear device, the axial end surface of the cylindrical portion is rotatable relative to the separating plate. This mechanism retains lubricant. It is also capable of preventing foreign particles from entering the planetary gear system. A planetary gear device is a great choice if your planetary motor’s speed is high. A high-quality planetary gear system can provide a superior performance than conventional systems.

A planetary gear system is a complex mechanism, involving three moving links that are connected to each other through joints. The sun gear acts as an input and the planet gears act as outputs. They rotate about their axes at a ratio determined by the number of teeth on each gear. The sun gear has 24 teeth, while the planet gears have three-quarters that ratio. This ratio makes a planetary motor extremely efficient.

planetary gear train

To predict the free vibration response of a planetary motor gear train, it is essential to develop a mathematical model for the system. Previously, static and dynamic models were used to study the behavior of planetary motor gear trains. In this study, a dynamic model was developed to investigate the effects of key design parameters on the vibratory response. Key parameters for planetary gear transmissions include the structure stiffness and mesh stiffness, and the mass and location of the shaft and bearing supports.

The design of the planetary motor gear train consists of several stages that can run with variable input speeds. The design of the gear train enables the transmission of high torques by dividing the load across multiple planetary gears. In addition, the planetary gear train has multiple teeth which mesh simultaneously in operation. This design also allows for higher efficiency and transmittable torque. Here are some other advantages of planetary motor gear trains. All these advantages make planetary motor gear trains one of the most popular types of planetary motors.

The compact footprint of planetary gears allows for excellent heat dissipation. High speeds and sustained performances will require lubrication. This lubricant can also reduce noise and vibration. But if these characteristics are not desirable for your application, you can choose a different gear type. Alternatively, if you want to maintain high performance, a planetary motor gear train will be the best choice. So, what are the advantages of planetary motor gears?

planetary gear train with fixed carrier train ratio

The planetary gear train is a common type of transmission in various machines. Its main advantages are high efficiency, compactness, large transmission ratio, and power-to-weight ratio. This type of gear train is a combination of spur gears, single-helical gears, and herringbone gears. Herringbone planetary gears have lower axial force and high load carrying capacity. Herringbone planetary gears are commonly used in heavy machinery and transmissions of large vehicles.

To use a planetary gear train with a fixed carrier train ratio, the first and second planets must be in a carrier position. The first planet is rotated so that its teeth mesh with the sun’s. The second planet, however, cannot rotate. It must be in a carrier position so that it can mesh with the sun. This requires a high degree of precision, so the planetary gear train is usually made of multiple sets. A little analysis will simplify this design.

The planetary gear train is made up of three components. The outer ring gear is supported by a ring gear. Each gear is positioned at a specific angle relative to one another. This allows the gears to rotate at a fixed rate while transferring the motion. This design is also popular in bicycles and other small vehicles. If the planetary gear train has several stages, multiple ring gears may be shared. A stationary ring gear is also used in pencil sharpener mechanisms. Planet gears are extended into cylindrical cutters. The ring gear is stationary and the planet gears rotate around a sun axis. In the case of this design, the outer ring gear will have a -3/2 planet gear ratio.

planetary gear train with zero helix angle

The torque distribution in a planetary gear is skewed, and this will drastically reduce the load carrying capacity of a needle bearing, and therefore the life of the bearing. To better understand how this can affect a gear train, we will examine two studies conducted on the load distribution of a planetary gear with a zero helix angle. The first study was done with a highly specialized program from the bearing manufacturer INA/FAG. The red line represents the load distribution along a needle roller in a zero helix gear, while the green line corresponds to the same distribution of loads in a 15 degree helix angle gear.

Another method for determining a gear’s helix angle is to consider the ratio of the sun and planet gears. While the sun gear is normally on the input side, the planet gears are on the output side. The sun gear is stationary. The two gears are in engagement with a ring gear that rotates 45 degrees clockwise. Both gears are attached to pins that support the planet gears. In the figure below, you can see the tangential and axial gear mesh forces on a planetary gear train.

Another method used for calculating power loss in a planetary gear train is the use of an auto transmission. This type of gear provides balanced performance in both power efficiency and load capacity. Despite the complexities, this method provides a more accurate analysis of how the helix angle affects power loss in a planetary gear train. If you’re interested in reducing the power loss of a planetary gear train, read on!

planetary gear train with spur gears

A planetary gearset is a type of mechanical drive system that uses spur gears that move in opposite directions within a plane. Spur gears are one of the more basic types of gears, as they don’t require any specialty cuts or angles to work. Instead, spur gears use a complex tooth shape to determine where the teeth will make contact. This in turn, will determine the amount of power, torque, and speed they can produce.

A two-stage planetary gear train with spur gears is also possible to run at variable input speeds. For such a setup, a mathematical model of the gear train is developed. Simulation of the dynamic behaviour highlights the non-stationary effects, and the results are in good agreement with the experimental data. As the ratio of spur gears to spur gears is not constant, it is called a dedendum.

A planetary gear train with spur gears is a type of epicyclic gear train. In this case, spur gears run between gears that contain both internal and external teeth. The circumferential motion of the spur gears is analogous to the rotation of planets in the solar system. There are four main components of a planetary gear train. The planet gear is positioned inside the sun gear and rotates to transfer motion to the sun gear. The planet gears are mounted on a joint carrier that is connected to the output shaft.

planetary gear train with helical gears

A planetary gear train with helical teeth is an extremely powerful transmission system that can provide high levels of power density. Helical gears are used to increase efficiency by providing a more efficient alternative to conventional worm gears. This type of transmission has the potential to improve the overall performance of a system, and its benefits extend far beyond the power density. But what makes this transmission system so appealing? What are the key factors to consider when designing this type of transmission system?

The most basic planetary train consists of the sun gear, planet gear, and ring gear elements. The number of planets varies, but the basic structure of planetary gears is similar. A simple planetary geartrain has the sun gear driving a carrier assembly. The number of planets can be as low as two or as high as six. A planetary gear train has a low mass inertia and is compact and reliable.

The mesh phase properties of a planetary gear train are particularly important in designing the profiles. Various parameters such as mesh phase difference and tooth profile modifications must be studied in depth in order to fully understand the dynamic characteristics of a PGT. These factors, together with others, determine the helical gears’ performance. It is therefore essential to understand the mesh phase of a planetary gear train to design it effectively.

editor by czh 2022-12-17

in London United Kingdom sales price shop near me near me shop factory supplier Atg Pgh Series Square Flange Helical Gear Planetary Reducer for Motor manufacturer best Cost Custom Cheap wholesaler

Ever-Energy Group CO., LTD. IS Expert IN Creating ALL Sorts OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Speed REDUCERS, PARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Equipment REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Automobile GEARBOXES, PTO Travel SHAFTS, Specific REDUCER & Connected Equipment Components AND OTHER Relevant Goods, SPROCKETS, HYDRAULIC System, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Minimal BACKLASH WORM REDUCERS AND SO ON. There is a specialized heart of province amount, EPG academician doing work station, experiment station for EPG post medical doctors, and countrywide 863 plan set up in EPG group. With these platforms and strong technical capability, the far more than 400 experts have created all assortment of unique higher specific and high power products, executed mould applications for crucial elements in the vehicle and nationwide business revitalizing program, ensuing a lot more than 5000 designed more than, between which 33 things are autonomous patent technology with four patent approved . ensures the stability and consistency of the key perform of components. PGH SERERS

Goods Characteristics:

(1) Low Sounds:UnEPTT65db.

(2) Reduced Backlash:Backlash is unEPTT3 arcmin . Backlash for two-phase speed reduction is with in 5 arcmin.

(3) EPT Effectiveness:one-phase up to 95% or more,2-phase up to 92% or more.

(4) EPT Enter Velocity:Input velocity enables for up to 8000RPM.

(five) EPT Torque:EPT torque output than that of typical planetary EPT EPTTs

(six) Upkeep-Cost-free:Lower grease use,can be life time lubrication

(seven) EPT Speed Reduction Ratio:Pace ratio is in excess of 1/one thousand.

Benefit:

Use:

- Aerospace,army sector.

- Health-related overall health,electronic data industry.

- Market robots,Creation EPTT,CNC EPTT instrument producing sector.

- EPT,EPT,EPT,Foodstuff,EPTlurgical.

- EPTal security engineering,Warehouse EPT market.

Model ILLUMINATE:

Equipment BOX Performance Details:

| MODUL NO. | Stage | RATIO sup1 | PGH42 | PGH60 | PGH90 | PGH115 | PGH142 | PGH180 | PGH220 | |

| Rated output torque T2N | Nm | one | 3 | twenty | fifty five | one hundred thirty | 208 | 342 | 588 | 1,one hundred forty |

| 4 | 19 | fifty | a hundred and forty | 290 | 542 | 1,050 | one,seven hundred | |||

| 5 | 22 | 60 | one hundred sixty | 330 | 650 | 1,200 | 2,000 | |||

| six | twenty | fifty five | 150 | 310 | 600 | 1,a hundred | one,900 | |||

| seven | 19 | 35 | 140 | 300 | 550 | 1,100 | one,800 | |||

| 8 | seventeen | 37 | a hundred and twenty | 260 | 500 | one,000 | one,600 | |||

| ten | 14 | 55 | 95 | 220 | 370 | 800 | 1,220 | |||

| two | twelve | twenty | 55 | 130 | 208 | 342 | 588 | one,one hundred forty | ||

| fifteen | 20 | 50 | 130 | 208 | 342 | 588 | 1,a hundred and forty | |||

| twenty | 19 | 60 | a hundred and forty | 290 | 542 | 1,050 | one,seven hundred | |||

| twenty five | 22 | 60 | 160 | 330 | 650 | one,200 | 2,000 | |||

| thirty | 22 | sixty | a hundred and sixty | 330 | 650 | 1,two hundred | 2,000 | |||

| 35 | 22 | 60 | 160 | 330 | 650 | 1,200 | 2,000 | |||

| forty | 22 | 60 | a hundred and sixty | 330 | 650 | one,200 | 2,000 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1,200 | two,000 | |||

| sixty | 20 | fifty five | a hundred and fifty | 310 | 600 | 1,100 | one,900 | |||

| 70 | 19 | 35 | one hundred forty | 300 | 50 | 1,one hundred | one,800 | |||

| eighty | seventeen | 35 | one hundred twenty | 260 | 500 | 1,000 | one,600 | |||

| 100 | fourteen | 37 | ninety five | 220 | 370 | 800 | 1,220 | |||

| MAX. output torqueT2B | Nm | 1,2 | 3~one hundred | three moments of Nominal Output Torque | ||||||

| Rated input speed n1 | rpm | one,two | three~a hundred | five,000 | 5,000 | 4,000 | four,000 | three,000 | 3,000 | two,000 |

| MAX.enter speed n1B | rpm | one,2 | three~a hundred | ten,000 | ten,000 | eight,000 | eight,000 | six,000 | 6,000 | four,000 |

| EPT Backlash P0 | arcmin | one | three~10 | – | – | le1 | le1 | le1 | le1 | le1 |

| 2 | twelve~one hundred | – | – | – | le3 | le3 | le3 | le3 | ||

| EPT Backlash P1 | arcmin | one | 3~10 | le3 | le3 | le3 | le3 | le3 | le3 | le3 |

| 2 | 12~one hundred | le5 | le5 | le5 | le5 | le5 | le5 | le5 | ||

| StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd Backlash P2 | arcmin | 1 | 3~10 | le5 | le5 | le5 | le5 | le5 | le5 | le5 |

| 2 | twelve~one hundred | le7 | le7 | le7 | le7 | le7 | le7 | le7 | ||

| Torsional stiffness | Nm/arcmin | one,2 | 3~one hundred | three | 7 | fourteen | twenty five | fifty | a hundred forty five | 225 |

| Max.radial power F2rB sup2 | N | one,two | 3~a hundred | 780 | 1,530 | 3,250 | 6,700 | nine,four hundred | 14,five hundred | fifty,000 |

| MAX.aXiHu (West EPT) Dis.al power F2a1B sup2 | N | 1,2 | three~100 | 350 | ||||||

| MAX.aXiHu (West EPT) Dis.al force F2a2B sup2 | N | 1,two | three~a hundred | 390 | ||||||

| 1,two | three~100 | twenty,000* | ||||||||

| Work effectiveness eta | % | one | 3~10 | ge97 | ||||||

| 2 | 12~one hundred | ge94 | ||||||||

| Excess weight | kg | one | three~ten | .5 | ||||||

| 2 | 12~one hundred | .eight | ||||||||

| Functioning temperature | ordmC | 1,two | 3~100 | -ten ordmC~ 90 ordmC | ||||||

| Lubrication | one,two | 3~a hundred | Artificial lubricating oil | |||||||

| Defense degree | 1,2 | 3~a hundred | IP65 | |||||||

| Installation route | 1,2 | three~one hundred | Any direction | |||||||

| Sounds degree(n1=3000rpm) | dB | one,2 | three~100 | le56 | le58 | le60 | le63 | le65 | le67 | le70 |

Outline DIMENSION:

Firm See:

HangEPT EPTEPTTndeyi EPT amp EPT EPTT, Ltd. is a subsidiary of EPTTiwan Jun Yi EPTTry. Jun Yi EPTTry was established in March 1972. The company EPTTizes in the design, deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment and manufacturing of substantial-tech different EPTed motors and helical EPT EPTTs, worm and worm EPT EPTTs and planetary EPTTs. Our items sold to a lot more than thirty countries about the globe and win good track record and quite a few awards in the overEPTT market for numerous years. In modern a long time, to accomplish EPTT generation and give outstanding services,we established up subsidiary of creation of planetary EPT EPTT in EPTT.

Historical past:

1972:EPTTiwan Jun Yi EPTTry is founded.

1989:It estabEPTTd a overEPTT branch company ATRUMP EPTTRY INC in Los Angeles

1995:Pass the ISO9002 EPTT certification.

2003:Pass the ISO9001 top quality certification and the European CE stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd test which enabled the items to be bought in Europe

2013:The business set up subsidiary in EPTT to attain EPTT creation.

Manufacturing facility:

Wisdom Manufactured In ATG,Knowledge The EPT.

EPT:

INSPECTION EPT:

FAQ:

(one) Can I be your agent?

Yes, welcome to deep cooperation. We have massive advertising of ATG brand name in the market place now. For the details remember to speak to me.

(two) Is OEM obtainable?

Indeed, OEM is offered. We have specialist designer to aid your manufacturer marketing.

(3) How can I get a sample to verify your high quality?

Soon after value affirmation, you can need for samples to examine our good quality. Totally free for the samples, but you need to have to pay out for the freight.

(4)What’s your top quality guarantee?

We have different sorts of items which can fulfill distinct high quality stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd.

Our QC department will test items ahead of shipping. We have a hundred% good quality ensure to buyers. We will be liable for any top quality problem.

(5) How about the shipping and delivery time?

The shipping and delivery time is dependent on the products and the quantity. But EPTTly, the shipping time for a container is about one particular month.

Welcome to our firm.

If any dilemma, really feel cost-free to go away message on the base of this page.

in Tabuk Saudi Arabia sales price shop near me near me shop factory supplier Custom Sintered Auto Gear Parts Speed Gear Reducer Small Planetary Motor Gearbox Transmission 12V 24V, 36V Gearbox with Input Output Flange manufacturer best Cost Custom Cheap wholesaler

In addition, all our generation techniques are in compliance with ISO9002 requirements. PersonnelOur income people are effectively skilled to accommodate your requests and converse English for your usefulness. We are seeking forward to developing successful company interactions with new customers all around the planet in the future. Our principal goods, steel EPTes ,gear elements for motors via powEPTmetallurgy processing.

We EPTize in developing and manufacturing highly engineered, custom made gear components , EPT , parts and assemblies. Our professional staff are geared towards providing consumers with large high quality merchandise and excellent support .

A EPT is a EPT EPT device to generate high torque by lowering the travel pace or increase the drive velocity the other way. Planetary EPT consisting 3 factors: EPTgear, planet equipment and ring gear . A EPT gear is a gearwheel in a planetary gear technique, that rotates close to its possess aXiHu (West Lake) Dis.s and has other gears (world gears) that rotate all around it. Significantly like the EPT and planets in our solar technique. EPT volume of planetary gears in a EPT differs primarily based on the equipment ratio. Most planetary EPTes have from two to 5 planet gears. When looking at planetary gears, the toughness of the EPT is generally determined by the size of the EPTgear. More substantial EPTgears will allow for larger torque values. EPT planet carrier,Its aim is to maintain up to gears of the very same dimensions, which mesh with the EPTgear. In a simple planetary EPT set up, enter EPT turns the EPTgear at higher velocity. EPT planets, spaced around the central aXiHu (West Lake) Dis.s of rotation, mesh with the EPTas nicely as the mounted ring gear, so they are compelled to orbit as they roll. All the planets are mounted to a single rotating member, named carrier. As the planet provider turns, it delivers lower-velocity, high-torque output. EPT EPT Gear Gets EPT Enter Whilst EPT three World Gears Supply EPT Ouput By way of A World Provider .

Our EPT,LigEPT bodyweight,small size, substantial carrying potential, EPT support life .Smooth procedure, low sound, big output torque, massive velocity ratio, higher performance, EPT diversion, and multi-tooth meshing by powEPTmetallurgy method .

EPT ratio 3 to one thousand .

Customized steel parts specification

| Merchandise type | personalized gear parts ,OEM planetary gear areas , pace EPT , motor gears , custom made motor EPT |

| EPT | metal |

| Procedure | PowEPTmetallurgy , steel injection molding , cnc machining |

| Therapy | plating ,sand blasting , PVD , coating |

| Tolerance | plusmn0.3% |

| Drawing format | DWG ,IGS , STP |

| Delivery time | ten daEPTfor mass production |

PowEPTmetallurgy (PM) is a steel parts / elements fabrication way and made from steel powders material . EPT approach of powEPTmetallurgy (PM) is blending fine powEPTmaterials , push them into a desired form or kind compacting , and heating the compressed materials in a controlled atmosphere to bond the substance sintering .PM method can keep away from , or drastically lessen the want to use steel removing procedures,thereby significantly minimizing produce losses in manufacture and oftern resulting in reduced expenses .

EPT powEPTmetallurgy (PM) consist a few steps : powEPTblending,compaction and sintering .Frequent merchandise incEPT gears , structural metal areas , bushings used for cars , appliances and powEPTequipments .

Benefits of powEPTmetallurgy

EPT created by powEPTmetallurgy (PM) EPTly do not want more finishing , because makes excellent surface area complete.

Maintains shut dimensional tolerances

Offers components which could be warmth handled for enhanced power or increased put on resistance .

EPTre is considerably less wastage of uncooked material , can be really economical for mass creation .

Intricate designs elements can be manufactured . Gives managed porosity for self-lubrication or filtration.

Suits to higher volume areas productions needs .

Personalized steel elements

Workshop

in Durban South Africa sales price shop near me near me shop factory supplier Nmrv 075 Flange 80b5 Aluminum Housing Worm Reducer manufacturer best Cost Custom Cheap wholesaler

With a lot of years’ expertise in these lines, we have been distinguished from other suppliers in China by our benefits in competitive pricing, on-time supply, prompt responses, on-hand engineering help and excellent following-product sales solutions. Our technicians and engineers have 23 several years of Expertise in the Bearing Sector. “We are usually serving our clients with our very best items.”

Technical knowledge listing:

| Type: | Worm Gear Pace EPT |

| Design: | NMRV571–one hundred fifty |

| Ratio: | 1:seven.5,ten,fifteen,20,25,30,40,fifty,sixty,80,100 |

| Shade: | EPTlue/Silver Or On Buyer Ask for |

| Materials | Housing: EPTlue-Colored Cast-Iron Worm Equipment-Copper-ten-3# Worm-20CrMn Ti with carburizing and quenching, area harness is 56-62HRC Shaft-chromium metal-forty five# |

| Lubricant: | Synthetic ampMineral |

| EPTearing: | C ampU EPTearing |

| Seal: | NAK SKF |

| Guarantee: | -30-40 degC |

| ICE FLANGE | 80EPT5,90EPT5,100EPT5,112EPT5,132EPT5,160EPT5 |

| Rated EPT: | .06KW,.12KW,.25KW,.75KW,one.5KW,3KW,5.5KW,7.5KW |

| Application | Metallurgical EPTry, food EPTry, phase EPTry, welding EPTry, street EPTry, amusement EPTs, EPT EPTry, Rubber and plastic EPTry, environmental security EPTry ,engineering EPTry, development EPTry, EPT tool business, automotive business, logistics and transportation and so on |

| NMRV | PAM | N | M | P | D | |||||||||||

| ICE | 5 | 7.5 | 10 | fifteen | twenty | 25 | thirty | forty | 50 | sixty | 80 | a hundred | ||||

| twenty five | 56EPT14 | 50 | sixty five | 80 | 9 | nine | 9 | nine | nine | nine | 9 | nine | 9 | |||

| thirty | 63EPT5 | 95 | 115 | a hundred and forty | 11 | 11 | 11 | 11 | 11 | eleven | 11 | 11 | eleven | |||

| 63EPT14 | sixty | seventy five | ninety | |||||||||||||

| 56EPT5 | 80 | 100 | 120 | 9 | 9 | 9 | nine | 9 | 9 | 9 | 9 | nine | nine | nine | ||

| 56EPT14 | 50 | sixty five | 80 | |||||||||||||

| 40 | 71EPT5 | a hundred and ten | a hundred thirty | a hundred and sixty | 14 | 14 | 14 | 14 | 14 | 14 | 14 | fourteen | ||||

| 71EPT14 | 70 | 85 | one zero five | |||||||||||||

| 63EPT5 | ninety five | a hundred and fifteen | a hundred and forty | 11 | eleven | 11 | eleven | eleven | 11 | eleven | 11 | eleven | eleven | eleven | eleven | |

| 63EPT14 | sixty | 75 | ninety | |||||||||||||

| 56EPT5 | eighty | 100 | 120 | 9 | 9 | nine | 9 | |||||||||

| 50 | 80EPT5 | one hundred thirty | a hundred sixty five | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | |||||

| 80EPT14 | 80 | a hundred | 120 | |||||||||||||

| 71EPT5 | one hundred ten | a hundred thirty | a hundred and sixty | fourteen | fourteen | 14 | fourteen | 14 | 14 | 14 | fourteen | 14 | fourteen | fourteen | ||

| 71EPT14 | 70 | 85 | one hundred and five | |||||||||||||

| 63EPT5 | 95 | a hundred and fifteen | 140 | eleven | 11 | eleven | eleven | 11 | ||||||||

| sixty three | 90EPT5 | 130 | one hundred sixty five | 200 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||

| 90EPT14 | ninety five | a hundred and fifteen | one hundred forty | |||||||||||||

| 80EPT5 | one hundred thirty | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | ||||

| 80EPT14 | 80 | 100 | a hundred and twenty | |||||||||||||

| 71EPT5 | one hundred ten | a hundred thirty | one hundred sixty | fourteen | fourteen | 14 | fourteen | fourteen | ||||||||

| 71EPT14 | 70 | eighty five | one hundred and five | |||||||||||||

| 75 | a hundred/112EPT5 | 180 | 215 | 250 | 28 | 28 | 28 | |||||||||

| 100/112EPT14 | 110 | one hundred thirty | one hundred fifty | |||||||||||||

| 90EPT5 | 130 | a hundred sixty five | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||

| 90EPT14 | ninety five | 115 | a hundred and forty | |||||||||||||

| 80EPT5 | a hundred thirty | 165 | two hundred | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | |||||

| 80EPT14 | 80 | one hundred | 120 | |||||||||||||

| 71EPT5 | 110 | one hundred thirty | a hundred and sixty | fourteen | fourteen | fourteen | fourteen | |||||||||

| 90 | a hundred/112EPT5 | one hundred ninety | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | ||||||

| a hundred/112EPT14 | a hundred and ten | one hundred thirty | 160 | |||||||||||||

| 90EPT5 | one hundred thirty | one hundred sixty five | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||

| 90EPT14 | 95 | a hundred and fifteen | 140 | |||||||||||||

| 80EPT5 | one hundred thirty | a hundred sixty five | two hundred | 19 | 19 | 19 | 19 | 19 | ||||||||

| 80EPT14 | eighty | 100 | a hundred and twenty | |||||||||||||

| 110 | 132EPT5 | 230 | 265 | three hundred | 38 | 38 | 38 | 38 | ||||||||

| a hundred/112EPT5 | a hundred and eighty | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | ||||

| 90EPT5 | one hundred thirty | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||

| 80EPT5 | 130 | a hundred sixty five | 200 | 19 | 19 | |||||||||||

| one hundred thirty | 132EPT5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | 38 | 38 | 38 | |||||

| a hundred/112EPT5 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | ||||||

| 90EPT5 | 130 | 165 | 200 | 24 | 24 | |||||||||||

| one hundred fifty | 160EPT5 | 250 | 300 | 350 | 42 | 42 | forty two | 42 | 42 | |||||||

| 132EPT5 | 230 | 265 | 250 | 38 | 38 | 38 | 38 | 38 | 38 | |||||||

| one hundred/112EPT5 | one hundred eighty | 215 | 200 | 28 | 28 | 28 | 28 | |||||||||

Elements:

one. Housing: Die-solid Aluminum Alloy EPT (RV571~RV090)

Solid Iron EPT (RV110~RV150)

two. Worm Wheel: Wearable Tin EPTronze Alloy, Aluminum EPTronze Alloy

three. Worm Shaft: 20Cr Metal, carburizing, quenching, grinding, area hardness fifty six-62HRC, .three-.5mm remaining carburized layer after precise grinding

4. Enter Configurations:

Geared up with Electric Motors (AC Motor, EPTrake Motor, DC Motor, Servo Motor)

IEC-normalized Motor Flange

Sound Shaft Input

Worm Shaft EPTil Extension Enter

5. Output Configurations: Keyed Hollow Shaft Output

Hollow Shaft with Output Flange

Plug-in Sound Shaft Output

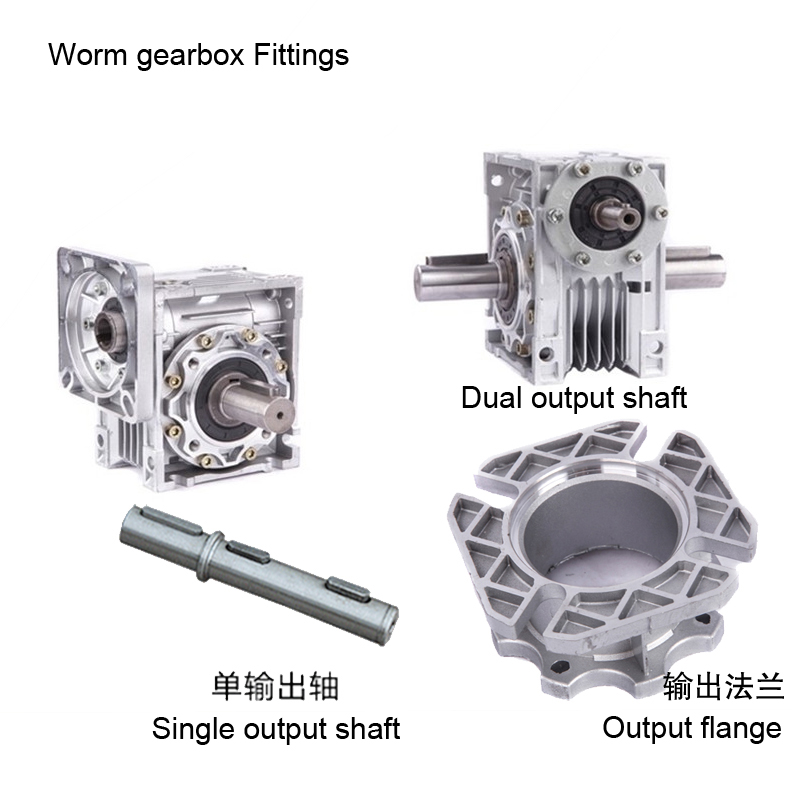

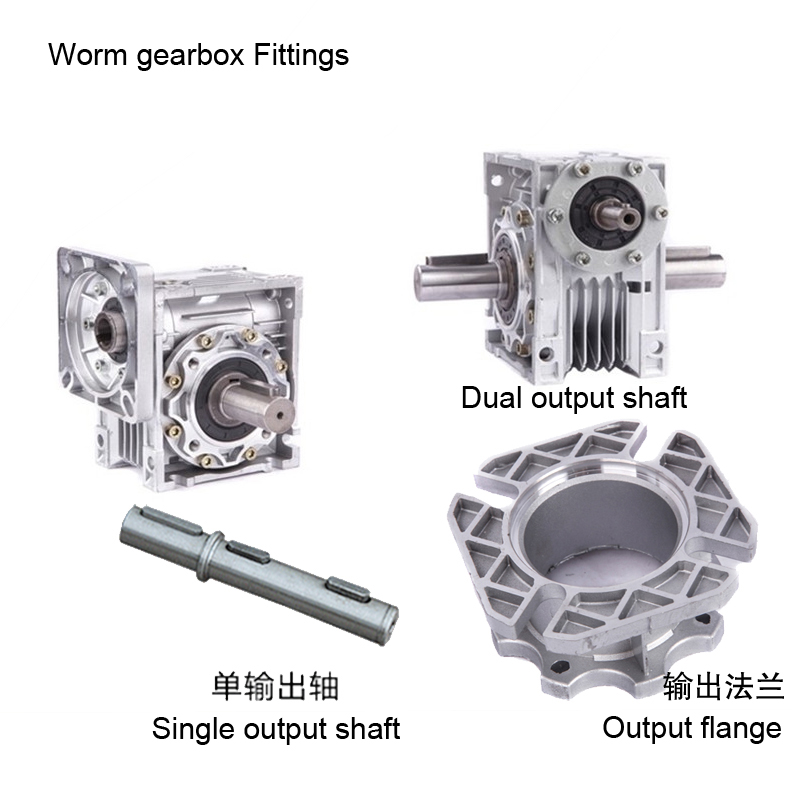

six. Spare Areas: Worm Shaft EPTil Extension, One Output Shaft, Double Output Shaft, Output Flange, Torque Arm, Dust Protect

seven. EPT Portray:

Aluminum Alloy EPT:

Following Shot EPTlasting, Anticorrosion Treatment method and Phosphating, Paint with the Coloration of RAL 5571 Gentian EPTlue or RAL 7035 LigEPT Grey

Solid Iron EPT:

After Portray with Crimson Antirust Paint, Paint with the Colour of RAL 5571 Gentian EPTlue

Workshop present

FAQ

Qone. What is your conditions of EPT?

A: EPTly, we pack our products in solitary color box. If you have EPT ask for about EPT, pls negotiate with us EPT, we can pack the products as your ask for.

Q2. What is your conditions of payment?

A: T/T thirty% as deposit, and 70% just before delivery. We’ll display you the images of the merchandise and deals

before you pay the harmony. Other payments terms, pls negotiate with us EPT, we can talk about.

Q3. What is your phrases of shipping?

A: EXW, FOEPT, CFR, CEPT.

Q4. How about your supply time?

A: EPTly, it will just take 25 to 30 daEPTafter obtaining your progress payment. The distinct delivery time depends

on the things and the quantity of your purchase.

Q5. Can you create in accordance to the samples?

A: Yes, we can generate by your samples or specialized drawings. We can construct the molds and fixtures.

Q6. What is your sample plan?

A: We can offer the sample if we have ready elements in inventory, but the consumers have to pay out the sample price and

the courier expense.We welcome sample get.

Q7. Do you check all your merchandise prior to supply?

A: Sure, we have 100% examination just before shipping

Q8: How do you make our business EPT-term and very good partnership?

1. We maintain excellent top quality and competitive cost to guarantee our clients gain

two. We respect each and every buyer as our good friend and we sincerely do company and make pals with them,

no matter in which they occur from.

in Kolhapur India sales price shop near me near me shop factory supplier Right-Angle Flange Moutned Planetary Gearbox Reducer manufacturer best Cost Custom Cheap wholesaler

We will supply ideal solutions and high top quality products with all sincerity. we offer 1-quit solution for the obtain of mechanical power transmission goods in China. In this way, our goods have continued to achieve market place acceptance and customers fulfillment more than the past number of many years. Appropriate-Angle Flange Moutned Planetary EPT EPT

Technical knowledge:

one. Ratio selection: 3.fifteen-9000

two. Input EPT: .twenty five-55KW

3. Allow torque rang: le 800000N. M

4. Output speed: .425-445 r/min

5. Structure mode: Likelihood of flange, foot, or shaft mounting remedies

Characteristic:

one. Wide and extensive assortment of N collection for EPT purposes

two. Lower pace shaft layout: Cylindrical with crucial, splined, hollow with shrink disc or splined hollow shaft

3. Rigid and exact nodular solid iron casing

4. Minimal sound operating, substantial manufacturing high quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd

5. Large and reliable functionality, load capability and low velocity shaft bearing

Characteristic of Foot Mounted Substantial Torque Planetary EPT :

1. The vast and thorough variety of N series for EPT apps

two. Minimal-velocity shaft design and style: Cylindrical with key, splined, hollow with shrink disc or splined hollow shaft

3. Rigid and precise nodular solid iron casing

four. Lower noise operating, high production good quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd

five. Substantial and reliable efficiency, load potential and lower-speed shaft bearing

| Ratio | 3.15:one to 9000:one |

| Reduction Stages | up to six reduction stages in one particular EPT |

| Nominal Output Torque | up to 800,000N.m |

in Bauchi Nigeria sales price shop near me near me shop factory supplier Small Flange Mounted Helical Worm Gear Reducer manufacturer best Cost Custom Cheap wholesaler

our items are marketing well in the American, European, South American and Asian markets. guarantees the security and consistency of the important purpose of components. we have received the trust of consumers throughout the world. EWS series adopts helical gear – worm gear speed EPT motor integrated push to increase the torque and performance of the pace EPT with wide assortment of rotating velocity and very good EPTity, it is applicable to varied installation modes and attributes protected and dependable overall performance, and EPT support life, additionally, it also complies with the global stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd.

Characteristic benefit

1.Mix of helical equipment and worm, vertical output, compact framework, large speed ratio.

2.The concave-convex surface area of the merchandise offers the perform of heat dissipation, and features powerful vibration absorption, minimal temperature rise, minimal noise.

3.The item functions higher generate precision, and is eEPTly appropriate for the internet site with repeated start off, is can be linked with diverse velocity EPTs and configuring diverse motor drives, and can be put in at the ninety ordm generate procedure internet site.

Specification parameter

Installation sort : Foot,flange,little flange,torque arm.

Output variety : Sound shaft,hollow shaft,hollow shaft with shrink disk,spline hollow shaft.

Input sort : Motor,enter shaft and flange

technical parameters : ratio i=23.8~389,combination of EWS/EWR is up to26688

Performance : ratio i=23.8~389,seventy seven%ratio i=73.7~389,sixty two%and mixture of EWS/EWR57%.

EPT Software

EPT Plant Tools

Metallurgical Business

Metal Forming EPTry

Petrochemical Sector

Mining EPT

Hoisting EPTry

Development Sector

Environmental Protection Sector

Cable Market

Food EPTry

Certificates

Handed quot ISO 9001 Intercontinental EPT Technique Certification quot, quotEurope CE Certificate quot, quot Swiss SGS Certification quot, quotHigh-tech EPTrprise certification of ZheJiang metropolis quot, quotExcellent functionality management EPTrprise of ZheJiang city quot,etc.

FAQ

1. Q: Can you make as per customized drawing?

A: Indeed, we offer you personalized services for customers.

two. Q: Are you a manufacturing facility or investing firm?

A. We are manufacturer in ZheJiang EPT.

3. Q: What is your MOQ?

A: 1 piece.

4. Q: What is actually your generation time?

A: seven-fifteen working daEPTafter getting payment.

five. Q: What is actually your payment phrases?

A: T/T, thirty% payment EPT, 70% harmony payment ought to be paid prior to transport.

six. Q: What’s your bundle?

A: In picket box EPT.

ZheJiang EPT Equipment EPT Co.,Ltd., previous a joint enterprise invested by is a ZheJiang EAST PUMP Group and Nicely Firm of The united states.We are expert maker of the gear EPTs and EPTize in the gear EPTs region in EPT for 20 a long time. EPT has outstanding R ampD team,top-ranking production and test tools.So we have the powerful EPT in the deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ing and production the stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds sort as properly as the customized sort gear EPT for our buyers.

in Riga Latvia sales price shop near me near me shop factory supplier Standard IEC Input Flange Worm Gear Reducer with Motor manufacturer best Cost Custom Cheap wholesaler

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

in Kampala Uganda sales price shop near me near me shop factory supplier Cycloidal Pin-Wheel Gear Reducer Bld Xld Flange Mount Reducer manufacturer best Cost Custom Cheap wholesaler

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

Best China manufacturer & factory Worm in Muzaffarpur India gear industrial sewing machine speed reducer flange mounted worm gearbox nmrv40 reducer with motor With high quality best price

With EPG brand name registered in much more than 70 international locations like America , Europe , Japan and so on, it has companions among planet best enterprises, this kind of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so forth.

Overview

Swift Details

- Relevant Industries:

-

Production Plant

- Model Name:

-

OEM

- Merchandise NO:

-

SYF

- Design Variety:

-

NMRV

- Solution Key phrases:

-

rv gearbox

- Shade:

-

Blue/Silver

- Product name:

-

Electrical power Transmission

- Software:

-

Stepper Motor

- Bearing:

-

NSK

- Certification:

-

ISO9001

- Ratio:

-

five-one hundred

- Mounting Placement:

-

Foot Mounted. Flange Mounted

Packaging & Delivery

-

Lead Time

: -

Quantity(Items) 1 – one hundred >100 Est. Time(days) 2 To be negotiated

On-line Customization

Mounting Dimension

The merchandise are broadly utilized in the producing equipments of all sorts of industries inside and outside China. They are the best choices for these days contemporary facilities of mechanical minimizing drive control to understand huge twisting length, large equipment ratio, little noise, high performance and security.

|

Model: |

NMRV025, 030, 040, 050, 063, 075, 090, a hundred and ten, a hundred thirty, 150 |

|

Ratio: |

1:5,7.5,ten,15,20,25,thirty,40,50,sixty,eighty,100 |

|

Shade: |

Blue, Silver Or On Consumer Ask for |

|

Sounds: |

reduced noise (<50DB) |

|

Edge: |

Efficient and secure functioning |

|

Materials: |

Housing: Die-Solid Aluminum Alloy |

|

Worm Gear-Bronze 9-4# |

|

|

Worm-20CrMnTi with carburizing and quenching, area harness is 56-62HRC |

|

|

Shaft-chromium metal-forty five# |

|

|

Packing: |

Carton and Wood Situation |

|

Bearing: |

C&U Bearing |

|

Seal: |

NAK SKF |

|

Certificate: |

ISO9001,CE,3C,OEM |

|

Guarantee: |

twelve months |

|

Input Electrical power: |

.06kw, .09kw, .12kw, .18kw, .25kw, .37kw, .55kw, .75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

|

Usages: |

Industrial Machine: Foodstuff Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

|

Lubricant: |

Synthetic & Mineral |

Firm profile

HangZhou EPT Team – 1 of the greatest gearbox producer in China – Electromechanical Services Co. Ltd

HangZhou EPT Team – one of the greatest gearbox company in China – Electromechanical Products Co., Ltd.is a present enterprise integrating development, style, generation and product sales,Principal promoting items consist of reducer motor,h2o pump,building equipment and components,bearings,components and electrical products,plastic merchandise,Labour security equipment.Our organization constantly adhere to the operation concept which is made up of individuals-oriented, innovation as the soul,be geared up for threat in times of peace, unremitting……

Item Deseription

Solitary Phase Worm Gear Reducer.

The reducer which model is twenty five~ninety produced of Aluminum alloy die-casting box,good hunting in physical appearance,compact in framework,rust proofing on area and small quantity to save mounting room.

It could be explained that the conditions under which irreversibility can come about are as follows: The reducer design of a hundred and ten~150 is produced of cast iron which casted with Aluminum mould.It`s good looking and strong, and can be utilised via the setting of multi-azimuth.

Good radiating characterstic sales opportunities protected and dependability,and high effectiveness for utilizing.

The sturdy ability of loading guarantee steady transmission,make significantly less vibration and sound.

Differs of connecting composition for electricity input and torque output meet up with various call for-meritsthe design of box define and the established of foot hole with excellent versality is apt to a lot of types of mounting.

The NMRV worm gearbox is new generation of goods by our manufacturing unit on the foundation of perfecting WJ series items with compromise of innovative engineering both at house and overseas.It really is apprearance adopts sophisticated sq. box structure.It really is outer body is created of higher high quality aluminium alloy die casting into forming.It’s modest in quantity,light excess weight,large in radiating performance,huge in output torque,sleek in working and reduced sound.It’s suitbale for all positions.

Strategy for product picked

You should realize the adhering to at first in purchase to delect the model of RV speed reducer properly.

– Loading issue

– Speed scope or ratio in application

– Operating condition and environment

– Set up space

Application region

Certifications

Comprehensive Images

Packing & Shipping

|

Packaging |

|

|

Measurement |

500 (L) * 500 (W) * 400 (D) |

|

Bodyweight |

1.2 T |

|

Packaging Specifics |

The typical package is picket box(Measurement: L*W*H). If export to european international locations,the picket box will be fumigated.If container is way too tigher,we will use pe movie for packing or pack it accordingClose up of two yokes with the common joint. Be aware the slight oozing of grease from the UJ seal finishes, the clump of grease is from inside the yoke splined shaft area –Generate (outer) yoke has a woman (usual spline) gap and “Y” condition conclude that is the universal joint (UJ) mount. –UJ is a cross formed casting obtaining roller bearings enclosed with caps at all four points and is held into the yoke with 4 “C” clips –Internal yoke and travel shaft is an additional yoke welded to the generate stop, of the push shaft. –Pushed shaft and internal yoke is the driven shaft that rides inside of the travel shaft and has a yoke welded at the driven finish –UJ yet another UJ as above to buyers unique request. |

|

Packaging |

|

|

Dimensions |

five hundred (L) * 500 (W) * four hundred (D) |

|

Weight |

one.2 T |

|

Packaging Information |

The standard package deal is wooden box(Dimensions: L*W*H). If export to european international locations,the picket box will be fumigated.If container is as well tigher,we will use pe film for packing or pack it according to customers special ask for. |

FAQ

Q1: Are you trading firm or manufacturer ?

A: We are a producer in ZheJiang China.welcome to our factory to have a go to.

Q2: How we decide on models and requirements?

A:You can electronic mail us the collection name & code (for illustration: WJ series worm gearbox) as effectively as need particulars, this sort of as motor energy, output pace or ratio, support issue or your application…as considerably info as achievable. If you can source some images or drawings, it is better.

Q3: How is your cost? Can you provide any discount?

A: We will give the best price we can base on your requirements and the portions.

Q4: How prolonged should I hold out for the feedback right after I ship the enquiry?

A: Within 12 several hours.

Q5: What is your solution guarantee interval?

A:We offOur merchandise is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The usa, Thailand, Pakistan, Indonesia, a lot more than sixty nations around the world and regions.er one yr guarantee given that the vessel departure date left China.

Q6: What industries are your gearboxes being utilised?

A:Our gearboxes are commonly utilized to metallurgical tools, mining tools, automation tools, foodstuff machinery, packaging tools, tobacco tools and so on.

Get in touch with us

Cellular: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Insert:No.789 ShenHua Street, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT Group – a single of the most significant gearbox company in China – Electromechanical Facilities Co. Ltd.