Product Description

Product Description

Model selection

1.Installation method: Horizontal ( foot) installation, Vertical ( flange) installation

2.Requirement for the output shaft of motor: 18,22,28,32,40,50mm

3.Power requirement: 100W, 200W….3700W

4.Speed of the motor you need

5.Ratio: Motor input speed/output speed. Or advise your required output speed. We have 3,5,10…1800

6.Voltage: Three phase 220V/380V 50/60Hz; Single phase 110, 220V 50/60Hz

7.Additional parts:DC 90V brake unit; Hand release brake unit; DC 24V brake unit, 110V forced draft fan; 220V forced draft fan.

8.Position of terminal box: view from output shaft

9.Wire inlet direction

GH:Horizontal installation gear motor

GV:Vertical installation gear motor

GHM:Horizontal installation straight gear motor

GVM:Vertical installation straight gear motor

GHD :Horizontal installation dual axis gear motor

GVD:Vertical installation dual axis gear motor

Features of AC Gear motor

1.Small size, light weight, knot no noise, compact, maintenance-free

2.High tightness. Geared motor output section has the configuration of seals and O-ring to avoid grease refluxing and damage of insulation aging .

3.High efficiency. The gear motor products using the new silicon steel stamping die design, high precision core, strong magnetic properties, geared motor cooling structure using the new shape .

4.Optimal design, the ST ( speed – torque ) features optimized so that gear motors can work for a variety of operating environments.

5.Customized, our company has developed its own design team, geared motors can be customized according to the customer ‘s specific needs specifications.

Application:

Various industrial production lines, coveyor machinery, food machinery, medical machinery, printing machinery, office facility, instrument, automatic mahjong machine

|

Output Shaft |

18 |

22 |

28 |

32 |

40 |

50 |

60 |

|

Ratio |

3~50 |

3~90 |

3~200 |

3~200 |

3~200 |

3~200 |

3~100 |

|

Power |

100W/200W |

100w. 200w. 400w |

1/4HP. 1/2HP, 1HP |

1/2HP, 1HP, 2HP |

1HP, 2HP, 3HP |

2.3.5.7.5.10(HP) |

7.5HP. 10HP |

|

Output Torque |

0.19~19.3 kg-m |

0.19~36 kg-m |

0.37~69 kg-m |

1.3~123 kg-m |

1.3~145 kg-m |

2.6~267 kg-m |

9.8~267 kg-m |

|

Output Speed (RPM) |

0.1~1800 |

0.1~1800 |

0.1~1800 |

0.1~1800 |

0.1~1800 |

0.1~1800

|

0.1~1800 |

Detailed Photos

Our Advantages

We have more than 30years on all kinds of ac motors and gearmotor ,worm reducers producing ,nice price

What we do:

1.Stamping of lamination

2.Rotor die-casting

3.Winding and inserting – both manual and semi-automatically

4.Vacuum varnishing

5.Machining shaft, housing, end shields, etc…

6.Rotor balancing

7.Painting – both wet paint and powder coating

8.assembly

9.Packing

10.Inspecting spare parts every processing

11.100% test after each process and final test before packing.,

FAQ

Q: Do you offer OEM service?

A: Yes

Q: What is your payment term?

A: 30% T/T in advance, 70% balance when receiving B/L copy. Or irrevocable L/C.

Q: What is your lead time?

A: About 30 days after receiving deposit or original L/C.

Q: What certifiicates do you have?

A: We have CE, ISO. And we can apply for specific certificate for different country such as SONCAP for Nigeria, COI for Iran, SASO for Saudi Arabia, etc

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Helical |

| Gear Shape: | Helical |

| Step: | Three-Step |

| Samples: |

US$ 96/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What are the maintenance requirements for gear motors, and how can longevity be maximized?

Gear motors, like any mechanical system, require regular maintenance to ensure optimal performance and longevity. Proper maintenance practices help prevent failures, minimize downtime, and extend the lifespan of gear motors. Here are some maintenance requirements for gear motors and ways to maximize their longevity:

1. Lubrication:

Regular lubrication is essential for gear motors to reduce friction, wear, and heat generation. The gears, bearings, and other moving parts should be properly lubricated according to the manufacturer’s recommendations. Lubricants should be selected based on the motor’s specifications and operating conditions. Regular inspection and replenishment of lubricants, as well as periodic oil or grease changes, should be performed to maintain optimal lubrication levels and ensure long-lasting performance.

2. Inspection and Cleaning:

Regular inspection and cleaning of gear motors are crucial for identifying any signs of wear, damage, or contamination. Inspecting the gears, bearings, shafts, and connections can help detect any abnormalities or misalignments. Cleaning the motor’s exterior and ventilation channels to remove dust, debris, or moisture buildup is also important in preventing malfunctions and maintaining proper cooling. Any loose or damaged components should be repaired or replaced promptly.

3. Temperature and Environmental Considerations:

Monitoring and controlling the temperature and environmental conditions surrounding gear motors can significantly impact their longevity. Excessive heat can degrade lubricants, damage insulation, and lead to premature component failure. Ensuring proper ventilation, heat dissipation, and avoiding overloading the motor can help manage temperature effectively. Similarly, protecting gear motors from moisture, dust, chemicals, and other environmental contaminants is vital to prevent corrosion and damage.

4. Load Monitoring and Optimization:

Monitoring and optimizing the load placed on gear motors can contribute to their longevity. Operating gear motors within their specified load and speed ranges helps prevent excessive stress, overheating, and premature wear. Avoiding sudden and frequent acceleration or deceleration, as well as preventing overloading or continuous operation near the motor’s maximum capacity, can extend its lifespan.

5. Alignment and Vibration Analysis:

Proper alignment of gear motor components, such as gears, couplings, and shafts, is crucial for smooth and efficient operation. Misalignment can lead to increased friction, noise, and premature wear. Regularly checking and adjusting alignment, as well as performing vibration analysis, can help identify any misalignment or excessive vibration that may indicate underlying issues. Addressing alignment and vibration problems promptly can prevent further damage and maximize the motor’s longevity.

6. Preventive Maintenance and Regular Inspections:

Implementing a preventive maintenance program is essential for gear motors. This includes establishing a schedule for routine inspections, lubrication, and cleaning, as well as conducting periodic performance tests and measurements. Following the manufacturer’s guidelines and recommendations for maintenance tasks, such as belt tension checks, bearing replacements, or gear inspections, can help identify and address potential issues before they escalate into major failures.

By adhering to these maintenance requirements and best practices, the longevity of gear motors can be maximized. Regular maintenance, proper lubrication, load optimization, temperature control, and timely repairs or replacements of worn components contribute to the reliable operation and extended lifespan of gear motors.

Are there environmental benefits to using gear motors in certain applications?

Yes, there are several environmental benefits associated with the use of gear motors in certain applications. Gear motors offer advantages that can contribute to increased energy efficiency, reduced resource consumption, and lower environmental impact. Here’s a detailed explanation of the environmental benefits of using gear motors:

1. Energy Efficiency:

Gear motors can improve energy efficiency in various ways:

- Torque Conversion: Gear reduction allows gear motors to deliver higher torque output while operating at lower speeds. This enables the motor to perform tasks that require high torque, such as lifting heavy loads or driving machinery with high inertia, more efficiently. By matching the motor’s power characteristics to the load requirements, gear motors can operate closer to their peak efficiency, minimizing energy waste.

- Controlled Speed: Gear reduction provides finer control over the motor’s rotational speed. This allows for more precise speed regulation, reducing the likelihood of energy overconsumption and optimizing energy usage.

2. Reduced Resource Consumption:

The use of gear motors can lead to reduced resource consumption and environmental impact:

- Smaller Motor Size: Gear reduction allows gear motors to deliver higher torque with smaller, more compact motors. This reduction in motor size translates to reduced material and resource requirements during manufacturing. It also enables the use of smaller and lighter equipment, which can contribute to energy savings during operation and transportation.

- Extended Motor Lifespan: The gear mechanism in gear motors helps reduce the load and stress on the motor itself. By distributing the load more evenly, gear motors can help extend the lifespan of the motor, reducing the need for frequent replacements and the associated resource consumption.

3. Noise Reduction:

Gear motors can contribute to a quieter and more environmentally friendly working environment:

- Noise Dampening: Gear reduction can help reduce the noise generated by the motor. The gear mechanism acts as a noise dampener, absorbing and dispersing vibrations and reducing overall noise emission. This is particularly beneficial in applications where noise reduction is important, such as residential areas, offices, or noise-sensitive environments.

4. Precision and Control:

Gear motors offer enhanced precision and control, which can lead to environmental benefits:

- Precise Positioning: Gear motors, especially stepper motors and servo motors, provide precise positioning capabilities. This accuracy allows for more efficient use of resources, minimizing waste and optimizing the performance of machinery or systems.

- Optimized Control: Gear motors enable precise control over speed, torque, and movement. This control allows for better optimization of processes, reducing energy consumption and minimizing unnecessary wear and tear on equipment.

In summary, using gear motors in certain applications can have significant environmental benefits. Gear motors offer improved energy efficiency, reduced resource consumption, noise reduction, and enhanced precision and control. These advantages contribute to lower energy consumption, reduced environmental impact, and a more sustainable approach to power transmission and control. When selecting motor systems for specific applications, considering the environmental benefits of gear motors can help promote energy efficiency and sustainability.

How does the gearing mechanism in a gear motor contribute to torque and speed control?

The gearing mechanism in a gear motor plays a crucial role in controlling torque and speed. By utilizing different gear ratios and configurations, the gearing mechanism allows for precise manipulation of these parameters. Here’s a detailed explanation of how the gearing mechanism contributes to torque and speed control in a gear motor:

The gearing mechanism consists of multiple gears with varying sizes, tooth configurations, and arrangements. Each gear in the system engages with another gear, creating a mechanical connection. When the motor rotates, it drives the rotation of the first gear, which then transfers the motion to subsequent gears, ultimately resulting in the output shaft’s rotation.

Torque Control:

The gearing mechanism in a gear motor enables torque control through the principle of mechanical advantage. The gear system utilizes gears with different numbers of teeth, known as gear ratio, to adjust the torque output. When a smaller gear (pinion) engages with a larger gear (gear), the pinion rotates faster than the gear but exerts more force or torque. This results in torque amplification, allowing the gear motor to deliver higher torque at the output shaft while reducing the rotational speed. Conversely, if a larger gear engages with a smaller gear, torque reduction occurs, resulting in higher rotational speed at the output shaft.

By selecting the appropriate gear ratio, the gearing mechanism effectively adjusts the torque output of the gear motor to match the requirements of the application. This torque control capability is essential in applications that demand high torque for heavy lifting or overcoming resistance, as well as applications that require lower torque but higher rotational speed.

Speed Control:

The gearing mechanism also contributes to speed control in a gear motor. The gear ratio determines the relationship between the rotational speed of the input shaft (driven by the motor) and the output shaft. When a gear motor has a higher gear ratio (more teeth on the driven gear compared to the driving gear), it reduces the output speed while increasing the torque. Conversely, a lower gear ratio increases the output speed while reducing the torque.

By choosing the appropriate gear ratio, the gearing mechanism allows for precise speed control in a gear motor. This is particularly useful in applications that require specific speed ranges or variations, such as conveyor systems, robotic movements, or machinery that needs to operate at different speeds for different tasks. The speed control capability of the gearing mechanism enables the gear motor to match the desired speed requirements of the application accurately.

In summary, the gearing mechanism in a gear motor contributes to torque and speed control by utilizing different gear ratios and configurations. It enables torque amplification or reduction, depending on the gear arrangement, allowing the gear motor to deliver the required torque output. Additionally, the gear ratio also determines the relationship between the rotational speed of the input and output shafts, providing precise speed control. These torque and speed control capabilities make gear motors versatile and suitable for a wide range of applications in various industries.

editor by CX 2024-05-17

China factory Medium Motor with Shaft Mounting Flange Gearbox High Torque AC Reduction Gear Speed Reducer vacuum pump adapter

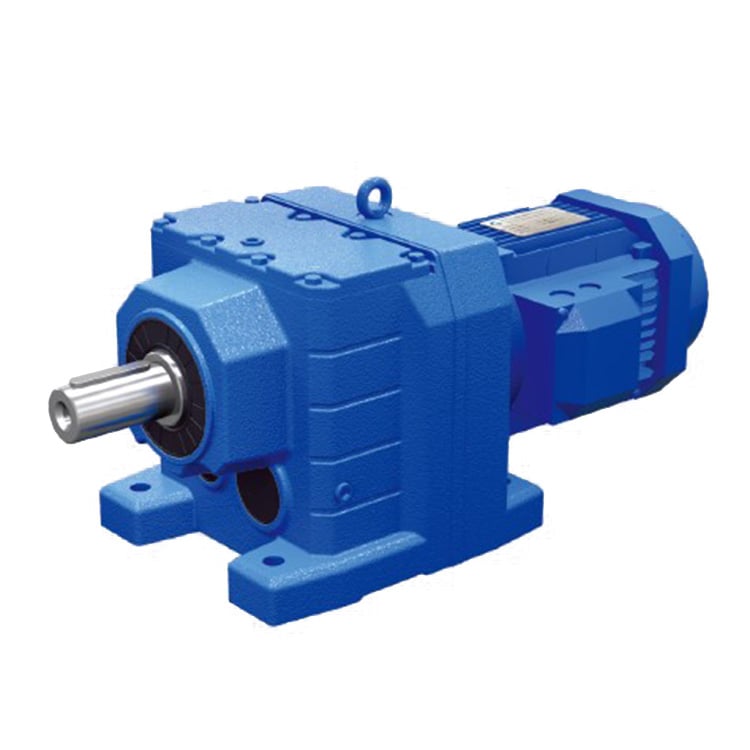

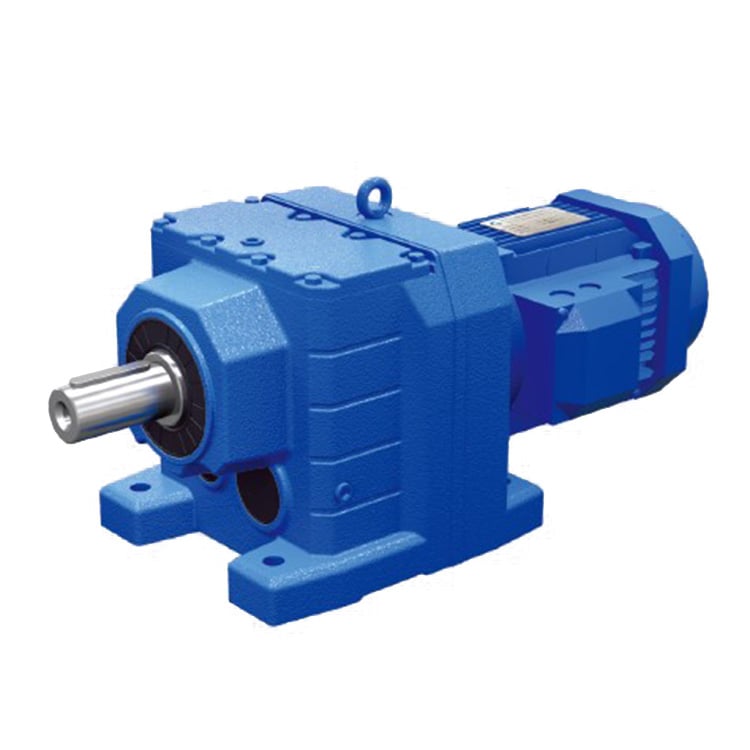

Product Description

3 Phase AC Reducer Motor 1/2hp 220V 380V 400W Gear Precision Foot Mounted Reducer Motor

CV and CH series motor can be designed as Single phase and 3 phases type. And power range is from 0.1KW to 3.7KW. The motor can be mounted with brake, and brake type is No excitation type. Material of gears is advanced special alloy steel and all gears are carburizing hardening. This gear motor has been added with senior lubricants, and no needs to added lubricants again.

Helical gear reducer has the characteristics of strong versatility, good combination, and strong bearing capacity, and has the advantages of easy access to various transmission ratios, high efficiency, small vibration, and high allowable axial and radial loads.

This series of products can not only be used in combination with various reducers and vibrators to meet the requirements, but also has the advantage of localization of related transmission equipment.

Mostly used in metallurgy, sewage treatment,chemical, pharmaceutical and other industries.

| Type | CH series three phase or single phase ac motors for industrial use | |

| Voltage | 220VAC, 380VAC, 415VAC | |

| Power range | Power range is 0.1KW to 3.7KW | |

| Output Speed | Speed range is from 7rpm to 500rpm | |

| Phase | Single phase and 3phases for choice | |

| Gears | Special alloy steel and high precise gears | |

| Grease | Good grease and no need add grease during using | |

| Cooling | Full closed fan | |

| USE | This motor is widely used in packing machine, textil machine |

motor is widely used in mix machine,elevator, conveyor,etc. |

| OEM Service | We offer OEM service. | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Bevel Gear |

| Step: | Three-Step |

| Samples: |

US$ 70/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about gear motors and their applications?

Individuals seeking to learn more about gear motors and their applications have access to various reliable resources that provide valuable information and insights. Here are some sources where individuals can find reliable information about gear motors:

1. Manufacturer Websites:

Manufacturer websites are a primary source of information about gear motors. Gear motor manufacturers often provide detailed product specifications, application guides, technical documentation, and educational materials on their websites. These resources offer insights into different gear motor types, features, performance characteristics, and application considerations. Manufacturer websites are a reliable and convenient starting point for learning about gear motors.

2. Industry Associations and Organizations:

Industry associations and organizations related to mechanical engineering, automation, and motion control often have resources and publications dedicated to gear motors. These organizations provide technical articles, whitepapers, industry standards, and guidelines related to gear motor design, selection, and application. Examples of such associations include the American Gear Manufacturers Association (AGMA), International Electrotechnical Commission (IEC), and Institute of Electrical and Electronics Engineers (IEEE).

3. Technical Publications and Journals:

Technical publications and journals focused on engineering, robotics, and motion control are valuable sources of in-depth knowledge about gear motors. Publications like IEEE Transactions on Industrial Electronics, Mechanical Engineering magazine, or Motion System Design magazine often feature articles, case studies, and research papers on gear motor technology, advancements, and applications. These publications provide authoritative and up-to-date information from industry experts and researchers.

4. Online Forums and Communities:

Online forums and communities dedicated to engineering, robotics, and automation can be excellent resources for discussions, insights, and practical experiences related to gear motors. Websites like Stack Exchange, engineering-focused subreddits, or specialized forums provide platforms for individuals to ask questions, share knowledge, and engage in discussions with professionals and enthusiasts in the field. Participating in these communities allows individuals to learn from real-world experiences and gain practical insights.

5. Educational Institutions and Courses:

Technical colleges, universities, and vocational training centers often offer courses or programs in mechanical engineering, mechatronics, or automation that cover gear motor fundamentals and applications. These educational institutions provide comprehensive curricula, textbooks, and lecture materials that can serve as reliable resources for individuals interested in learning about gear motors. Additionally, online learning platforms like Coursera, Udemy, or LinkedIn Learning offer courses on topics related to gear motors and motion control.

6. Trade Shows and Exhibitions:

Attending trade shows, exhibitions, and industry conferences related to automation, robotics, or motion control provides opportunities to learn about the latest advancements in gear motor technology. These events often feature product demonstrations, technical presentations, and expert panels where individuals can interact with gear motor manufacturers, industry experts, and other professionals. It’s a great way to stay updated on the latest trends, innovations, and applications of gear motors.

When seeking reliable resources, it’s important to consider the credibility of the source, the expertise of the authors, and the relevance to the specific area of interest. By leveraging these resources, individuals can gain a comprehensive understanding of gear motors and their applications, from basic principles to advanced topics, enabling them to make informed decisions and effectively utilize gear motors in their projects or applications.

Can you explain the role of backlash in gear motors and how it’s managed in design?

Backlash plays a significant role in gear motors and is an important consideration in their design and operation. Backlash refers to the slight clearance or play between the teeth of gears in a gear system. It affects the precision, accuracy, and responsiveness of the gear motor. Here’s an explanation of the role of backlash in gear motors and how it is managed in design:

1. Role of Backlash:

Backlash in gear motors can have both positive and negative effects:

- Compensation for Misalignment: Backlash can help compensate for minor misalignments between gears, shafts, or the load. It allows a small amount of movement before engaging the next set of teeth, reducing the risk of damage due to misalignment. This can be particularly beneficial in applications where precise alignment is challenging or subject to variations.

- Negative Impact on Accuracy and Responsiveness: Backlash can introduce a delay or “dead zone” in the motion transmission. When changing the direction of rotation or reversing the load, the gear teeth must first overcome the clearance or play before engaging in the opposite direction. This delay can reduce the overall accuracy, responsiveness, and repeatability of the gear motor, especially in applications that require precise positioning or rapid changes in direction or speed.

2. Managing Backlash in Design:

Designers employ various techniques to manage and minimize backlash in gear motors:

- Tight Manufacturing Tolerances: Proper manufacturing techniques and tight tolerances can help minimize backlash. Precision machining and quality control during the production of gears and gear components ensure closer tolerances, reducing the amount of play between gear teeth.

- Preload or Pre-tensioning: Applying a preload or pre-tensioning force to the gear system can help reduce backlash. This technique involves introducing an initial force or tension that eliminates the clearance between gear teeth. It ensures immediate contact and engagement of the gear teeth, minimizing the dead zone and improving the overall responsiveness and accuracy of the gear motor.

- Anti-Backlash Gears: Anti-backlash gears are designed specifically to minimize or eliminate backlash. They typically feature modifications to the gear tooth profile, such as modified tooth shapes or special tooth arrangements, to reduce clearance. Anti-backlash gears can be used in gear motor designs to improve precision and minimize the effects of backlash.

- Backlash Compensation: In some cases, backlash compensation techniques can be employed. These techniques involve monitoring the position or movement of the load and applying control algorithms to compensate for the backlash. By accounting for the clearance and adjusting the control signals accordingly, the effects of backlash can be mitigated, improving accuracy and responsiveness.

3. Application-Specific Considerations:

The management of backlash in gear motors should be tailored to the specific application requirements:

- Positioning Accuracy: Applications that require precise positioning, such as robotics or CNC machines, may require tighter backlash control to ensure accurate and repeatable movements.

- Dynamic Response: Applications that involve rapid changes in direction or speed, such as high-speed automation or servo control systems, may require reduced backlash to maintain responsiveness and minimize overshoot or lag.

- Load Characteristics: The nature of the load and its impact on the gear system should be considered. Heavy loads or applications with significant inertial forces may require additional backlash management techniques to maintain stability and accuracy.

In summary, backlash in gear motors can affect precision, accuracy, and responsiveness. While it can compensate for misalignments, backlash may introduce delays and reduce the overall performance of the gear motor. Designers manage backlash through tight manufacturing tolerances, preload techniques, anti-backlash gears, and backlash compensation methods. The management of backlash depends on the specific application requirements, considering factors such as positioning accuracy, dynamic response, and load characteristics.

How does the gearing mechanism in a gear motor contribute to torque and speed control?

The gearing mechanism in a gear motor plays a crucial role in controlling torque and speed. By utilizing different gear ratios and configurations, the gearing mechanism allows for precise manipulation of these parameters. Here’s a detailed explanation of how the gearing mechanism contributes to torque and speed control in a gear motor:

The gearing mechanism consists of multiple gears with varying sizes, tooth configurations, and arrangements. Each gear in the system engages with another gear, creating a mechanical connection. When the motor rotates, it drives the rotation of the first gear, which then transfers the motion to subsequent gears, ultimately resulting in the output shaft’s rotation.

Torque Control:

The gearing mechanism in a gear motor enables torque control through the principle of mechanical advantage. The gear system utilizes gears with different numbers of teeth, known as gear ratio, to adjust the torque output. When a smaller gear (pinion) engages with a larger gear (gear), the pinion rotates faster than the gear but exerts more force or torque. This results in torque amplification, allowing the gear motor to deliver higher torque at the output shaft while reducing the rotational speed. Conversely, if a larger gear engages with a smaller gear, torque reduction occurs, resulting in higher rotational speed at the output shaft.

By selecting the appropriate gear ratio, the gearing mechanism effectively adjusts the torque output of the gear motor to match the requirements of the application. This torque control capability is essential in applications that demand high torque for heavy lifting or overcoming resistance, as well as applications that require lower torque but higher rotational speed.

Speed Control:

The gearing mechanism also contributes to speed control in a gear motor. The gear ratio determines the relationship between the rotational speed of the input shaft (driven by the motor) and the output shaft. When a gear motor has a higher gear ratio (more teeth on the driven gear compared to the driving gear), it reduces the output speed while increasing the torque. Conversely, a lower gear ratio increases the output speed while reducing the torque.

By choosing the appropriate gear ratio, the gearing mechanism allows for precise speed control in a gear motor. This is particularly useful in applications that require specific speed ranges or variations, such as conveyor systems, robotic movements, or machinery that needs to operate at different speeds for different tasks. The speed control capability of the gearing mechanism enables the gear motor to match the desired speed requirements of the application accurately.

In summary, the gearing mechanism in a gear motor contributes to torque and speed control by utilizing different gear ratios and configurations. It enables torque amplification or reduction, depending on the gear arrangement, allowing the gear motor to deliver the required torque output. Additionally, the gear ratio also determines the relationship between the rotational speed of the input and output shafts, providing precise speed control. These torque and speed control capabilities make gear motors versatile and suitable for a wide range of applications in various industries.

editor by CX 2024-04-24

China Professional Best Price High Torque PA140 Helical Gear Planetary Gearbox Speed Reducer with Hot selling

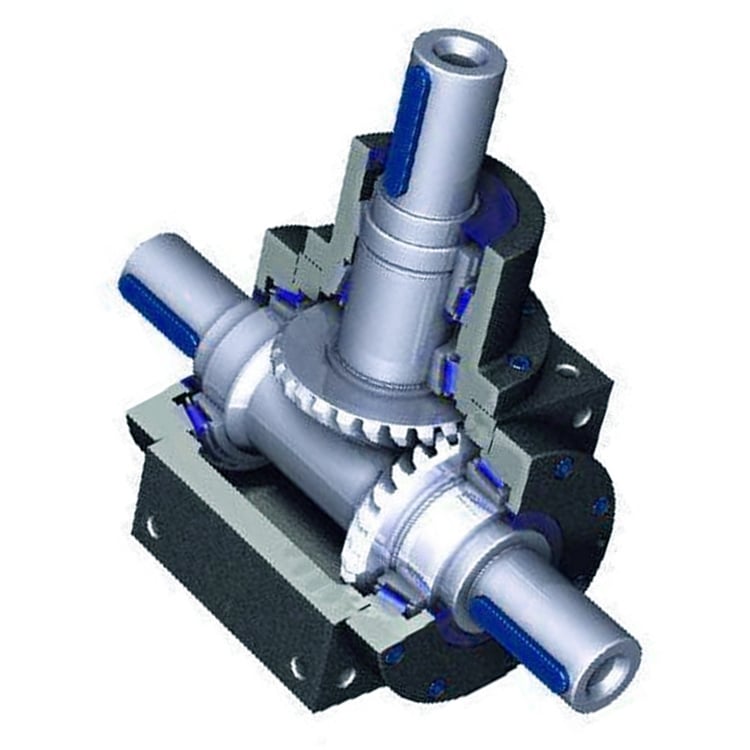

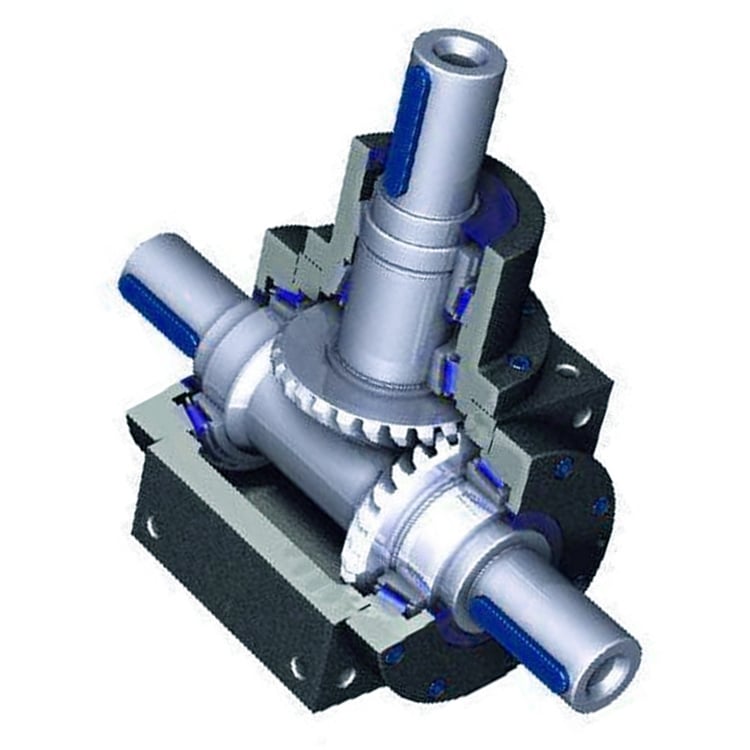

Product Description

Best Price High Torque PA140 Helical Gear Planetary Gearbox Speed Reducer

The high-precision planetary gearbox adopts spur gear design, and is used in various control transmission fields with servo motors, such as precision machine tools, laser cutting equipment, battery processing equipment, etc. It has the advantages of large torsional rigidity and large output torque.

*PA series helical gear shaft output planetary reducer

*PX series helical gear shaft output planetary reducer

*PG series helical gear flange output planetary reducer

*PW series helical gear shaft output planetary reducer

*PXR series helical gear right angle planetary reducer

*PAR series helical gear right angle planetary reducer

*PRF series spur gear shaft output planetary reducer

*PRL series spur gear shaft output planetary reducer

*PRN series spur gear flange output planetary reducer

*PFN series spur gear square output planetary reducer

*PVFN series spur gear 90 degree right angle planetary reducer

*PVLN series spur gear 90 degree right angle planetary reducer

Product Parameters

| Specifications | PA60 | PA90 | PA120 | PA140 | PA180 | PA220 | |||

| Technal Parameters | |||||||||

| Max. Torque | Nm | 1.5times rated torque | |||||||

| Emergency Stop Torque | Nm | 2.5times rated torque | |||||||

| Max. Radial Load | N | 1530 | 3250 | 6700 | 9400 | 14500 | 16500 | ||

| Max. Axial Load | N | 630 | 1300 | 3000 | 4700 | 7250 | 8250 | ||

| Torsional Rigidity | Nm/arcmin | 6 | 12 | 23 | 47 | 130 | 205 | ||

| Max.Input Speed | rpm | 8000 | 6000 | 6000 | 6000 | 6000 | 3000 | ||

| Rated Input Speed | rpm | 4000 | 3000 | 3000 | 3000 | 3000 | 1500 | ||

| Noise | dB | ≤58 | ≤60 | ≤65 | ≤68 | ≤68 | ≤72 | ||

| Average Life Time | h | 20000 | |||||||

| Efficiency Of Full Load | % | L1≥95% L2≥90% | |||||||

| Return Backlash | P1 | L1 | arcmin | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | arcmin | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| P2 | L1 | arcmin | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |

| L2 | arcmin | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| Moment Of Inertia Table | L1 | 3 | Kg*cm2 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.7 |

| 4 | Kg*cm2 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.61 | ||

| 5 | Kg*cm2 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.51 | ||

| 7 | Kg*cm2 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.92 | ||

| 8 | Kg*cm2 | 0.13 | 0.45 | 2.6 | 7.14 | / | / | ||

| 10 | Kg*cm2 | 0.13 | 0.4 | 2.57 | 7.03 | 22.51 | 50.18 | ||

| L2 | 12 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.63 | 7.3 | 23.59 | |

| 15 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.63 | 7.3 | 23.59 | ||

| 20 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.63 | 6.92 | 23.33 | ||

| 25 | Kg*cm2 | 0.13 | 0.45 | 0.4 | 2.63 | 6.92 | 22.68 | ||

| 28 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.43 | 6.92 | 23.33 | ||

| 30 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.43 | 7.3 | 25.59 | ||

| 35 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.43 | 6.92 | 22.68 | ||

| 40 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.43 | 6.92 | 23.33 | ||

| 50 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.39 | 6.92 | 22.68 | ||

| 70 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.39 | 6.72 | 22.68 | ||

| 100 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.39 | 6.72 | 22.68 | ||

| Technical Parameter | Level | Ratio | PA60 | PA90 | PA120 | PA140 | PA180 | PA220 | |

| Rated Torque | L1 | 3 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 |

| 4 | Nm | 45 | 130 | 230 | 480 | 880 | 1800 | ||

| 5 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 7 | Nm | 45 | 100 | 220 | 480 | 1100 | 1600 | ||

| 8 | Nm | 40 | 90 | 200 | 440 | / | / | ||

| 10 | Nm | 30 | 75 | 175 | 360 | 770 | 1200 | ||

| L2 | 12 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 | |

| 15 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 | ||

| 20 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 25 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 28 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 30 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 | ||

| 35 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 40 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 50 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 70 | Nm | 45 | 100 | 220 | 480 | 1100 | 1600 | ||

| 100 | Nm | 30 | 75 | 175 | 360 | 770 | 1200 | ||

| Degree Of Protection | IP65 | ||||||||

| Operation Temprature | ºC | – 10ºC to -90ºC | |||||||

| Weight | L1 | kg | 1.25 | 3.75 | 8.5 | 16 | 28.5 | 49.3 | |

| L2 | kg | 1.75 | 5.1 | 12 | 21.5 | 40 | 62.5 | ||

Company Profile

Packaging & Shipping

1. Lead time: 7-10 working days as usual, 20 working days in busy season, it will be based on the detailed order quantity;

2. Delivery: DHL/ UPS/ FEDEX/ EMS/ TNT

FAQ

1. who are we?

Hefa Group is based in ZheJiang , China, start from 1998,has a 3 subsidiaries in total.The Main Products is planetary gearbox,timing belt pulley, helical gear,spur gear,gear rack,gear ring,chain wheel,hollow rotating platform,module,etc

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.how to choose the suitable planetary gearbox?

First of all,we need you to be CZPT to provide relevant parameters.If you have a motor drawing,it will let us recommend a suitable gearbox for you faster.If not,we hope you can provide the following motor parameters:output speed,output torque,voltage,current,ip,noise,operating conditions,motor size and power,etc

4. why should you buy from us not from other suppliers?

We are a 22 years experiences manufacturer on making the gears, specializing in manufacturing all kinds of spur/bevel/helical gear, grinding gear, gear shaft, timing pulley, rack, planetary gear reducer, timing belt and such transmission gear parts

5. what services can we provide?

Accepted Delivery Terms: Fedex,DHL,UPS;

Accepted Payment Currency:USD,EUR,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union;

Language Spoken:English,Chinese,Japanese

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Automation Equipment |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Bevel Gear |

| Step: | Double-Step |

| Samples: |

US$ 350/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

The Benefits of Using a Gear Motor

A gear motor works on the principle of conservation of angular momentum. As the smaller gear covers more RPM and the larger gear produces more torque, the ratio between the two is greater than one. Similarly, a multiple gear motor follows the principle of energy conservation, with the direction of rotation always opposite to the one that is adjacent to it. It’s easy to understand the concept behind gear motors and the various types available. Read on to learn about the different types of gears and their applications.

Electric motor

The choice of an electric motor for gear motor is largely dependent on the application. There are various motor and gearhead combinations available, and some are more efficient than others. However, it is critical to understand the application requirements and select a motor that meets these needs. In this article, we’ll examine some of the benefits of using a gear motor. The pros and cons of each type are briefly discussed. You can buy new gear motors at competitive prices, but they aren’t the most reliable or durable option for your application.

To determine which motor is best for your application, you’ll need to consider the load and speed requirements. A gear motor’s efficiency (e) can be calculated by taking the input and output values and calculating their relation. On the graph below, the input (T) and output (P) values are represented as dashed lines. The input (I) value is represented as the torque applied to the motor shaft. The output (P) is the amount of mechanical energy converted. A DC gear motor is 70% efficient at 3.75 lb-in / 2,100 rpm.

In addition to the worm gear motor, you can also choose a compact DC worm gear motor with a variable gear ratio from 7.5 to 80. It has a range of options and can be custom-made for your specific application. The 3-phase AC gear motor, on the other hand, works at a rated power of one hp and torque of 1.143.2 kg-m. The output voltage is typically 220V.

Another important factor is the output shaft orientation. There are two main orientations for gearmotors: in-line and offset. In-line output shafts are most ideal for applications with high torque and short reduction ratios. If you want to avoid backlash, choose a right angle output shaft. An offset shaft can cause the output shaft to become excessively hot. If the output shaft is angled at a certain angle, it may be too large or too small.

Gear reducer

A gear reducer is a special kind of speed reducing motor, usually used in large machinery, such as compressors. These reducers have no cooling fan and are not designed to handle heavy loads. Different purposes require different service factors. For instance, a machine that requires frequent fast accelerations and occasional load spikes needs a gear reducer with a high service factor. A gear reducer that’s designed for long production shifts should be larger than a machine that uses it for short periods of time.

A gear reducer can reduce the speed of a motor by a factor of two. The reduction ratio changes the rotation speed of the receiving member. This change in speed is often required to solve problems of inertia mismatch. The torque density of a gear reducer is measured in newton meters and will depend on the motor used. The first criterion is the configuration of the input and output shafts. A gear ratio of 2:1, for example, means that the output speed has been cut in half.

Bevel gear reducers are a good option if the input and output shafts are perpendicular. This type is very robust and is perfect for situations where the angle between two axes is small. However, bevel gear reducers are expensive and require constant maintenance. They are usually used in heavy-duty conveyors and farm equipment. The correct choice of gear reducer for gear motor is crucial for the efficiency and reliability of the mechanism. To get the best gear reducer for your application, talk to a qualified manufacturer today.

Choosing a gear reducer for a gear motor can be tricky. The wrong one can ruin an entire machine, so it’s important to know the specifics. You must know the torque and speed requirements and choose a motor with the appropriate ratio. A gear reducer should also be compatible with the motor it’s intended for. In some cases, a smaller motor with a gear reducer will work better than a larger one.

Motor shaft

Proper alignment of the motor shaft can greatly improve the performance and life span of rotating devices. The proper alignment of motors and driven instruments enhances the transfer of energy from the motor to the instrument. Incorrect alignment leads to additional noise and vibration. It may also lead to premature failure of couplings and bearings. Misalignment also results in increased shaft and coupling temperatures. Hence, proper alignment is critical to improve the efficiency of the driven instrument.

When choosing the correct type of gear train for your motor, you need to consider its energy efficiency and the torque it can handle. A helical geared motor is more efficient for high output torque applications. Depending on the required speed and torque, you can choose between an in-line and a parallel helical geared motor. Both types of gears have their advantages and disadvantages. Spur gears are widespread. They are toothed and run parallel to the motor shaft.

A planetary gear motor can also have a linear output shaft. A stepping motor should not operate at too high current to prevent demagnetization, which will lead to step loss or torque drop. Ensure that the motor and gearbox output shafts are protected from external impacts. If the motor and gearbox are not protected against bumps, they may cause thread defects. Make sure that the motor shafts and rotors are protected from external impacts.

When choosing a metal for your gear motor’s motor shaft, you should consider the cost of hot-rolled bar stock. Its outer layers are more difficult to machine. This type of material contains residual stresses and other problems that make it difficult to machine. For these applications, you should choose a high-strength steel with hard outer layers. This type of steel is cheaper, but it also has size considerations. It’s best to test each material first to determine which one suits your needs.

In addition to reducing the speed of your device, a geared motor also minimizes the torque generated by your machine. It can be used with both AC and DC power. A high-quality gear motor is vital for stirring mechanisms and conveyor belts. However, you should choose a geared motor that uses high-grade gears and provides maximum efficiency. There are many types of planetary gear motors and gears on the market, and it’s important to choose the right one.

First stage gears

The first stage gears of a gear motor are the most important components of the entire device. The motor’s power transmission is 90% efficient, but there are many factors that can affect its performance. The gear ratios used should be high enough to handle the load, but not too high that they are limiting the motor’s speed. A gear motor should also have a healthy safety factor, and the lubricant must be sufficient to overcome any of these factors.

The transmission torque of the gear changes with its speed. The transmission torque at the input side of the gear decreases, transferring a small torque to the output side. The number of teeth and the pitch circle diameters can be used to calculate the torque. The first stage gears of gear motors can be categorized as spur gears, helical gears, or worm gears. These three types of gears have different torque capacities.

The first stage helical gear is the most important part of a gear motor. Its function is to transfer rotation from one gear to the other. Its output is the gearhead. The second stage gears are connected by a carrier. They work in tandem with the first stage gear to provide the output of the gearhead. Moreover, the first stage carrier rotates in the same direction as the input pinion.

Another important component is the output torque of the gearmotor. When choosing a gearmotor, consider the starting torque, running torque, output speed, overhung and shock loads, duty cycles, and more. It is crucial to choose a gearmotor with the right ratio for the application. By choosing the proper gearmotor, you will get maximum performance with minimal operating costs and increase plant productivity. For more information on first stage gears, check out our blog.

The first stage of a gear motor is composed of a set of fixed and rotating sprockets. The first stage of these gears acts as a drive gear. Its rotational mass is a limiting factor for torque. The second stage consists of a rotating shaft. This shaft rotates in the direction of the torque axis. It is also the limiting force for the motor’s torque.

editor by CX 2023-11-15

China best Hot Sale High Toruqe Helical Bevel Gear Speed Reducer For Motor worm gear motor

Warranty: 1 years

Applicable Industries: Building Material Shops, Construction works , Energy & Mining, Farms, Food & Beverage Factory, Food & Beverage Shops, Machinery Repair Shops, Manufacturing Plant, Printing Shops, Retail

Customized support: OBM, ODM, OEM

Gearing Arrangement: Planetary

Output Torque: 78 N.M

Input Speed: 3

Q1: What’re your main products?A1: High Precision Planetary Gearbox; High Precision Quality Wpa Transmission Gear Reducer Horizontal Gear Box Hollow Rotating Platform; Precision Steering Box; Worm Speed Reducer; Worm Screw Jack; R/K/F/S GearboxQ2: What industries are your gearboxes being used in?A2: Gearboxes are widely used in the areas of robotics, textile, food processing, beverage, chemical industry, escalator, automatic storage equipment, metallurgy, environmental protection, logistics, etc.Q3: Can you offer OEM or ODM service?A3: Yes, we are a professional manufacturer so we can do customized orders.Q4: How to choose a model?A4: We have one-1 service team for model selection, and we can provide CAD drawings and 3D models in 5 minutes with technical information of required output torque, output speed and motor parameters etc. So just contact us.Q5: What information shall we give before placing a purchase order?A5: We understand your needs from the following information: a) Type of the gearbox, ratio, input and output type, input flange, High Temperature Resistance NMRV Series 9-4 Copper Worm High Efficiency Durable Worm Gear Speed Reducer mounting position, and motor information etc.b) Housing color.c) Purchase quantity.d) Other special requirements.Q6: How long is the delivery time?A6: Most planetary gearboxes are in stock. 7 working days for worm speed reducer and worm screw jack, 15 working days for R/K/F/S gearbox.

The Difference Between Planetary Gears and Spur Gears

A spur gear is a type of mechanical drive that turns an external shaft. The angular velocity is proportional to the rpm and can be easily calculated from the gear ratio. However, to properly calculate angular velocity, it is necessary to know the number of teeth. Fortunately, there are several different types of spur gears. Here’s an overview of their main features. This article also discusses planetary gears, which are smaller, more robust, and more power-dense.

Planetary gears are a type of spur gear

One of the most significant differences between planetary gears and spurgears is the way that the two share the load. Planetary gears are much more efficient than spurgears, enabling high torque transfer in a small space. This is because planetary gears have multiple teeth instead of just one. They are also suitable for intermittent and constant operation. This article will cover some of the main benefits of planetary gears and their differences from spurgears.

While spur gears are more simple than planetary gears, they do have some key differences. In addition to being more basic, they do not require any special cuts or angles. Moreover, the tooth shape of spur gears is much more complex than those of planetary gears. The design determines where the teeth make contact and how much power is available. However, a planetary gear system will be more efficient if the teeth are lubricated internally.

In a planetary gear, there are three shafts: a sun gear, a planet carrier, and an external ring gear. A planetary gear is designed to allow the motion of one shaft to be arrested, while the other two work simultaneously. In addition to two-shaft operation, planetary gears can also be used in three-shaft operations, which are called temporary three-shaft operations. Temporary three-shaft operations are possible through frictional coupling.

Among the many benefits of planetary gears is their adaptability. As the load is shared between several planet gears, it is easier to switch gear ratios, so you do not need to purchase a new gearbox for every new application. Another major benefit of planetary gears is that they are highly resistant to high shock loads and demanding conditions. This means that they are used in many industries.

They are more robust

An epicyclic gear train is a type of transmission that uses concentric axes for input and output. This type of transmission is often used in vehicles with automatic transmissions, such as a Lamborghini Gallardo. It is also used in hybrid cars. These types of transmissions are also more robust than conventional planetary gears. However, they require more assembly time than a conventional parallel shaft gear.

An epicyclic gearing system has three basic components: an input, an output, and a carrier. The number of teeth in each gear determines the ratio of input rotation to output rotation. In some cases, an epicyclic gear system can be made with two planets. A third planet, known as the carrier, meshes with the second planet and the sun gear to provide reversibility. A ring gear is made of several components, and a planetary gear may contain many gears.

An epicyclic gear train can be built so that the planet gear rolls inside the pitch circle of an outer fixed gear ring, or “annular gear.” In such a case, the curve of the planet’s pitch circle is called a hypocycloid. When epicycle gear trains are used in combination with a sun gear, the planetary gear train is made up of both types. The sun gear is usually fixed, while the ring gear is driven.

Planetary gearing, also known as epicyclic gear, is more durable than other types of transmissions. Because planets are evenly distributed around the sun, they have an even distribution of gears. Because they are more robust, they can handle higher torques, reductions, and overhung loads. They are also more energy-dense and robust. In addition, planetary gearing is often able to be converted to various ratios.

They are more power dense

The planet gear and ring gear of a compound planetary transmission are epicyclic stages. One part of the planet gear meshes with the sun gear, while the other part of the gear drives the ring gear. Coast tooth flanks are used only when the gear drive works in reversed load direction. Asymmetry factor optimization equalizes the contact stress safety factors of a planetary gear. The permissible contact stress, sHPd, and the maximum operating contact stress (sHPc) are equalized by asymmetry factor optimization.

In addition, epicyclic gears are generally smaller and require fewer space than helical ones. They are commonly used as differential gears in speed frames and in looms, where they act as a Roper positive let off. They differ in the amount of overdrive and undergearing ratio they possess. The overdrive ratio varies from fifteen percent to forty percent. In contrast, the undergearing ratio ranges from 0.87:1 to 69%.

The TV7-117S turboprop engine gearbox is the first known application of epicyclic gears with asymmetric teeth. This gearbox was developed by the CZPT Corporation for the Ilyushin Il-114 turboprop plane. The TV7-117S’s gearbox arrangement consists of a first planetary-differential stage with three planet gears and a second solar-type coaxial stage with five planet gears. This arrangement gives epicyclic gears the highest power density.

Planetary gearing is more robust and power-dense than other types of gearing. They can withstand higher torques, reductions, and overhung loads. Their unique self-aligning properties also make them highly versatile in rugged applications. It is also more compact and lightweight. In addition to this, epicyclic gears are easier to manufacture than planetary gears. And as a bonus, they are much less expensive.

They are smaller

Epicyclic gears are small mechanical devices that have a central “sun” gear and one or more outer intermediate gears. These gears are held in a carrier or ring gear and have multiple mesh considerations. The system can be sized and speeded by dividing the required ratio by the number of teeth per gear. This process is known as gearing and is used in many types of gearing systems.

Planetary gears are also known as epicyclic gearing. They have input and output shafts that are coaxially arranged. Each planet contains a gear wheel that meshes with the sun gear. These gears are small and easy to manufacture. Another advantage of epicyclic gears is their robust design. They are easily converted into different ratios. They are also highly efficient. In addition, planetary gear trains can be designed to operate in multiple directions.

Another advantage of epicyclic gearing is their reduced size. They are often used for small-scale applications. The lower cost is associated with the reduced manufacturing time. Epicyclic gears should not be made on N/C milling machines. The epicyclic carrier should be cast and tooled on a single-purpose machine, which has several cutters cutting through material. The epicyclic carrier is smaller than the epicyclic gear.

Epicyclic gearing systems consist of three basic components: an input, an output, and a stationary component. The number of teeth in each gear determines the ratio of input rotation to output rotation. Typically, these gear sets are made of three separate pieces: the input gear, the output gear, and the stationary component. Depending on the size of the input and output gear, the ratio between the two components is greater than half.

They have higher gear ratios

The differences between epicyclic gears and regular, non-epicyclic gears are significant for many different applications. In particular, epicyclic gears have higher gear ratios. The reason behind this is that epicyclic gears require multiple mesh considerations. The epicyclic gears are designed to calculate the number of load application cycles per unit time. The sun gear, for example, is +1300 RPM. The planet gear, on the other hand, is +1700 RPM. The ring gear is also +1400 RPM, as determined by the number of teeth in each gear.

Torque is the twisting force of a gear, and the bigger the gear, the higher the torque. However, since the torque is also proportional to the size of the gear, bigger radii result in lower torque. In addition, smaller radii do not move cars faster, so the higher gear ratios do not move at highway speeds. The tradeoff between speed and torque is the gear ratio.

Planetary gears use multiple mechanisms to increase the gear ratio. Those using epicyclic gears have multiple gear sets, including a sun, a ring, and two planets. Moreover, the planetary gears are based on helical, bevel, and spur gears. In general, the higher gear ratios of epicyclic gears are superior to those of planetary gears.

Another example of planetary gears is the compound planet. This gear design has two different-sized gears on either end of a common casting. The large end engages the sun while the smaller end engages the annulus. The compound planets are sometimes necessary to achieve smaller steps in gear ratio. As with any gear, the correct alignment of planet pins is essential for proper operation. If the planets are not aligned properly, it may result in rough running or premature breakdown.

in Bishkek Kyrgyzstan sales price shop near me near me shop factory supplier High Quality Wpa Worm Gearbox Worm Gear Speed Reducer manufacturer best Cost Custom Cheap wholesaler

EPG has set up a comprehensive established of high quality management method which is provided with sophisticated inspection and take a look at gear. It has recognized stable cooperation with a lot of well identified universities and institutes in china this sort of as, Zhejiang College, Jilin College, Technological committee of nationwide chain push common, Institute of national chain travel, Zhejiang software engineering material institute, Huhan materials safety institute and it cooperated to identified China 1st Vehicle chain institute with Nationwide chain travel institute. The new merchandise include a collection of large-tech and large quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator action-chains, high-velocity tooth chains, timing chains, self-lubrication chains, between which have kind high speed tooth chain for car department dynamic box and aerial chains fill in the blanks of chain in China.

Higher good quality WPA worm EPT worm gear pace EPT

Elements:

one. Housing: Cast Iron

two. Gears: Worm Gears, one stage

3. Input Configurations:Reliable Enter Shaft,Motor Flange – IEC EPT5

4. Output Configurations:Reliable Output Shaft,Hollow Output Shaft

Functions:

one. Diverse variants, each enter and output shafts can be mounted horizontally or vertically

two. Compact composition

three. Immediate push or oblique drive available

four. Output could be solid shaft or hollow hole

Types amp Variants:

WPA Sequence – Lower Enter Shaft

WPS Sequence – Upper Enter Shaft

WPDA Sequence – Lower Enter Flange

WPDS Sequence – Upper Enter Flange

WPO Series – Vertical Upward Output Shaft

WPX Sequence – Vertical Downward Output Shaft

WPDO Sequence – Vertical Upward Output Shaft, Enter Flange

WPDX Series – Vertical Downward Output Shaft, Enter Flange

| Frame Dimension | CEPTr Length | Equipment Ratio |

| WPA40 | 40 |

10/1, fifteen/one, 20/one, twenty five/1, thirty/1, forty/one, fifty/1, 60/one |

| WPA50 | fifty | |

| WPA60 | 60 | |

| WPA70 | 70 | |

| WPA80 | eighty | |

| WPA100 | a hundred | |

| WPA120 | 120 | |

| WPA135 | a hundred thirty five | |

| WPA147 | 147 | |

| WPA155 | one hundred fifty five | |

| WPA175 | one hundred seventy five | |

| WPA200 | two hundred |

1. Far more than 35 many years encounter in R ampD and production, export equipment motors amp EPT EPTes.

2. StXiHu (West Lake) Dis.Hu (West Lake) Dis.rdization of the EPT sequence

3. Strong layout capability for big EPT amp personalized EPTes.

four. High high quality EPTes and established solutions company.

5. Strict top quality control procedure, stable top quality.

6. Significantly less than two% of the top quality problems.

seven. Modular layout, brief shipping time.

8. Quick reaction amp professional services.

EPT reg was established in 1982, which has more than 36 several years in R amp D and manufacturing of EPTes, gears, shaft, motor and spare elements.

We can offer the correct solution for uncountable applications. Our items are extensively employed in the ranges of metallurgical, metal, mining, pulp and paper, suXiHu (West Lake) Dis.Hu (West Lake) Dis. and alcohol marketplace and various other varieties of EPTs with a powerful presence in the international marketplace.

EPT reg has grow to be a reputable supplier, capable to source substantial quality EPTes.With 36 years expertise, we guarantee you the utmost reliability and security for each merchandise and companies.

in Genoa Italy sales price shop near me near me shop factory supplier Gear Reducer Box Gearbox Reducer Speed Drive Reduction Electric Motor Good Price Transmission Prices Variator Sumitomo Excavator High Rpm China Gear Reducer Box manufacturer best Cost Custom Cheap wholesaler

Furthermore, WE CAN Make Customized VARIATORS, GEARED MOTORS, Electric MOTORS AND OTHER HYDRAULIC Products According TO CUSTOMERS’ DRAWINGS. We are aiming to satisfy the needs of the clients close to the globe.. In this way, our merchandise have continued to obtain industry acceptance and buyers gratification in excess of the earlier couple of a long time.

Equipment EPT EPTox EPT EPT Pace Generate Reduction Electric powered Motor Very good Cost EPT Charges Variator Sumitomo Excavator High Rpm EPT Gear EPT EPTox

in Agartala India sales price shop near me near me shop factory supplier High Quality Hard Tooth Surface S K F R Speed Reducer K Series Helical Bevel Gear Reducer K47 Helical Gear Reducer manufacturer best Cost Custom Cheap wholesaler

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

China manufacturer & factory supplier for HangZhou in Meerut India EPG professional R17 helical gear speed reducer With high quality best price & service

Company of roller generate chains for electrical power transmission programs from standard industrial to functions in specialized locations this kind of as food processing, large development equipment, and oil field solutions. Available in double pitch travel and common roller chains with one and multiple strand configurations. Specifications incorporate .twenty five to 3 in. chain pitch, .thirteen to 1.88 in. length amongst sidebars, and .09 to .94 in. pin diameter. Obtainable with characteristics this kind of as scenario-hardened and armor-cased pins, pre-pressured procedure, corrosion and shock resistance, and stainless metal components. Gives submit-sale assistance solutions.The team has taken portion in the producing and revising of ISO/TC100 international chain normal several a long time in success and hosted the sixteenth ISO/TC100 International once-a-year conference in 2004.

Overview

Quick Specifics

- Applicable Industries:

-

Manufacturing Plant

- Gearing Arrangement:

-

Helical

- Product Number:

-

Adhering to “Survival by Quality, Growth by Technological innovation & Credit score”, The firm will continually improve solution performance to fulfill the growing consumer specifications in the demanding fashion of work.

R17-R167

PTO Shaft A PTO Adapter will be beneficial when functioning Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could trigger the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 stage hitch.

- Rated Energy:

-

.12kw-160kw

- Product identify:

-

Shanghai Goldgun skilled R17 helical gear speed reducer

- Model No.:

-

R17

- Ratio:

-

three.83 – 8164

- Input electricity ranking:

-

.twelve – .seventy five

- Pernissble torque (N .M):

-

87

- Color:

-

Silver Green Blue

- Certification:

-

ISO9001:2008

- Send inquiry:

-

commercial @goldgun.cn

Source Ability

- Offer Capability:

- 5000 Established/Sets for every Year

Packaging & Shipping

- Packaging Information

- Seaworthy wooden scenario

- Port

- Shanghai ,Ningbo,Shenzhen ,Tianjin ect

On the internet Customization

Item Info

Item Description

| Place of Origin | China |

| Model Identify | 202001EPG |

| Gearing Arrangement | Helical |

| Output Torque | 1.4~22900 |

| Enter Speed | 1400rpm |

| Output Pace | .06-1095rpm |

| China | Zhejiang |

| Model Quantity | R17-R167 |

| Rated Electrical power | .12kw-160kw |

| Item identify | Shanghai Goldgun specialist R17 helical gear velocity reducer |

| Design No. | R17 |

| Ratio | 3.83 – 8164 |

| Enter electricity ranking | .12 – .seventy five |

| Pernissble torque (N .M) | 87 |

| Coloration | Silver Inexperienced Blue |

| Certification | ISO9001:2008 |

| Ship inquiry | professional @goldgun.cn |

Product Screen

Item Screen

Related Goods

EK sequence helical- …

ER sequence helical …

S series Helical – …

CompanyInfo

Business Profile

Solution Process

Manufacturing Approach

Certifications

Certifications

user-described

Cargo & Payment

Our Rewards

A: Your inquiry relevant to our goods or rates will be replied in 24 several hours.

B: Protection of your income location, tips of layout and all your personal details.

C: Greatest quality and aggressive price.

……

faq

FAQ

1) How can I area buy?

A: You can contact us by email about your buy specifics, or location buy on line.

2) How can I shell out you?

A: After you verify our PI, we will request you to spend. T/T (HSBC bank) and Paypal, Western Union are the most usual techniques we are using.

……

Best China manufacturer & factory Worm in Muzaffarpur India gear industrial sewing machine speed reducer flange mounted worm gearbox nmrv40 reducer with motor With high quality best price

With EPG brand name registered in much more than 70 international locations like America , Europe , Japan and so on, it has companions among planet best enterprises, this kind of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so forth.

Overview

Swift Details

- Relevant Industries:

-

Production Plant

- Model Name:

-

OEM

- Merchandise NO:

-

SYF

- Design Variety:

-

NMRV

- Solution Key phrases:

-

rv gearbox

- Shade:

-

Blue/Silver

- Product name:

-

Electrical power Transmission

- Software:

-

Stepper Motor

- Bearing:

-

NSK

- Certification:

-

ISO9001

- Ratio:

-

five-one hundred

- Mounting Placement:

-

Foot Mounted. Flange Mounted

Packaging & Delivery

-

Lead Time

: -

Quantity(Items) 1 – one hundred >100 Est. Time(days) 2 To be negotiated

On-line Customization

Mounting Dimension

The merchandise are broadly utilized in the producing equipments of all sorts of industries inside and outside China. They are the best choices for these days contemporary facilities of mechanical minimizing drive control to understand huge twisting length, large equipment ratio, little noise, high performance and security.

|

Model: |

NMRV025, 030, 040, 050, 063, 075, 090, a hundred and ten, a hundred thirty, 150 |

|

Ratio: |

1:5,7.5,ten,15,20,25,thirty,40,50,sixty,eighty,100 |

|

Shade: |

Blue, Silver Or On Consumer Ask for |

|

Sounds: |

reduced noise (<50DB) |

|

Edge: |

Efficient and secure functioning |

|

Materials: |

Housing: Die-Solid Aluminum Alloy |

|

Worm Gear-Bronze 9-4# |

|

|

Worm-20CrMnTi with carburizing and quenching, area harness is 56-62HRC |

|

|

Shaft-chromium metal-forty five# |

|

|

Packing: |

Carton and Wood Situation |

|

Bearing: |

C&U Bearing |

|

Seal: |

NAK SKF |

|

Certificate: |

ISO9001,CE,3C,OEM |

|

Guarantee: |

twelve months |

|

Input Electrical power: |

.06kw, .09kw, .12kw, .18kw, .25kw, .37kw, .55kw, .75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

|

Usages: |

Industrial Machine: Foodstuff Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

|

Lubricant: |

Synthetic & Mineral |

Firm profile

HangZhou EPT Team – 1 of the greatest gearbox producer in China – Electromechanical Services Co. Ltd

HangZhou EPT Team – one of the greatest gearbox company in China – Electromechanical Products Co., Ltd.is a present enterprise integrating development, style, generation and product sales,Principal promoting items consist of reducer motor,h2o pump,building equipment and components,bearings,components and electrical products,plastic merchandise,Labour security equipment.Our organization constantly adhere to the operation concept which is made up of individuals-oriented, innovation as the soul,be geared up for threat in times of peace, unremitting……

Item Deseription

Solitary Phase Worm Gear Reducer.

The reducer which model is twenty five~ninety produced of Aluminum alloy die-casting box,good hunting in physical appearance,compact in framework,rust proofing on area and small quantity to save mounting room.

It could be explained that the conditions under which irreversibility can come about are as follows: The reducer design of a hundred and ten~150 is produced of cast iron which casted with Aluminum mould.It`s good looking and strong, and can be utilised via the setting of multi-azimuth.

Good radiating characterstic sales opportunities protected and dependability,and high effectiveness for utilizing.

The sturdy ability of loading guarantee steady transmission,make significantly less vibration and sound.

Differs of connecting composition for electricity input and torque output meet up with various call for-meritsthe design of box define and the established of foot hole with excellent versality is apt to a lot of types of mounting.

The NMRV worm gearbox is new generation of goods by our manufacturing unit on the foundation of perfecting WJ series items with compromise of innovative engineering both at house and overseas.It really is apprearance adopts sophisticated sq. box structure.It really is outer body is created of higher high quality aluminium alloy die casting into forming.It’s modest in quantity,light excess weight,large in radiating performance,huge in output torque,sleek in working and reduced sound.It’s suitbale for all positions.

Strategy for product picked

You should realize the adhering to at first in purchase to delect the model of RV speed reducer properly.

– Loading issue

– Speed scope or ratio in application

– Operating condition and environment

– Set up space

Application region

Certifications

Comprehensive Images

Packing & Shipping

|

Packaging |

|

|

Measurement |

500 (L) * 500 (W) * 400 (D) |

|

Bodyweight |

1.2 T |

|

Packaging Specifics |

The typical package is picket box(Measurement: L*W*H). If export to european international locations,the picket box will be fumigated.If container is way too tigher,we will use pe movie for packing or pack it accordingClose up of two yokes with the common joint. Be aware the slight oozing of grease from the UJ seal finishes, the clump of grease is from inside the yoke splined shaft area –Generate (outer) yoke has a woman (usual spline) gap and “Y” condition conclude that is the universal joint (UJ) mount. –UJ is a cross formed casting obtaining roller bearings enclosed with caps at all four points and is held into the yoke with 4 “C” clips –Internal yoke and travel shaft is an additional yoke welded to the generate stop, of the push shaft. –Pushed shaft and internal yoke is the driven shaft that rides inside of the travel shaft and has a yoke welded at the driven finish –UJ yet another UJ as above to buyers unique request. |

|

Packaging |

|

|

Dimensions |

five hundred (L) * 500 (W) * four hundred (D) |

|

Weight |

one.2 T |

|

Packaging Information |

The standard package deal is wooden box(Dimensions: L*W*H). If export to european international locations,the picket box will be fumigated.If container is as well tigher,we will use pe film for packing or pack it according to customers special ask for. |

FAQ

Q1: Are you trading firm or manufacturer ?

A: We are a producer in ZheJiang China.welcome to our factory to have a go to.

Q2: How we decide on models and requirements?

A:You can electronic mail us the collection name & code (for illustration: WJ series worm gearbox) as effectively as need particulars, this sort of as motor energy, output pace or ratio, support issue or your application…as considerably info as achievable. If you can source some images or drawings, it is better.

Q3: How is your cost? Can you provide any discount?

A: We will give the best price we can base on your requirements and the portions.

Q4: How prolonged should I hold out for the feedback right after I ship the enquiry?

A: Within 12 several hours.

Q5: What is your solution guarantee interval?

A:We offOur merchandise is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The usa, Thailand, Pakistan, Indonesia, a lot more than sixty nations around the world and regions.er one yr guarantee given that the vessel departure date left China.

Q6: What industries are your gearboxes being utilised?

A:Our gearboxes are commonly utilized to metallurgical tools, mining tools, automation tools, foodstuff machinery, packaging tools, tobacco tools and so on.

Get in touch with us

Cellular: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Insert:No.789 ShenHua Street, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT Group – a single of the most significant gearbox company in China – Electromechanical Facilities Co. Ltd.